Overview

Features

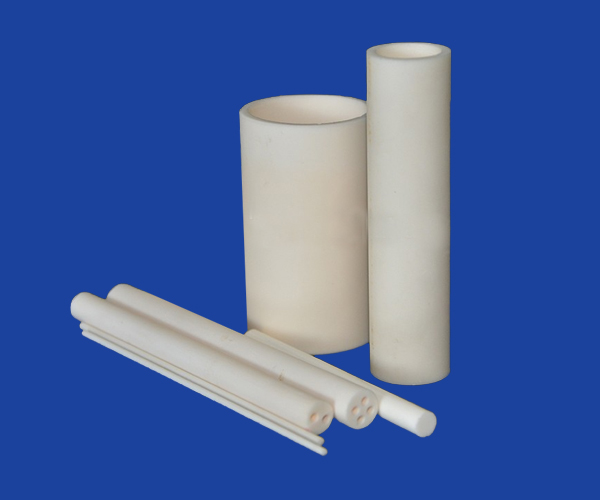

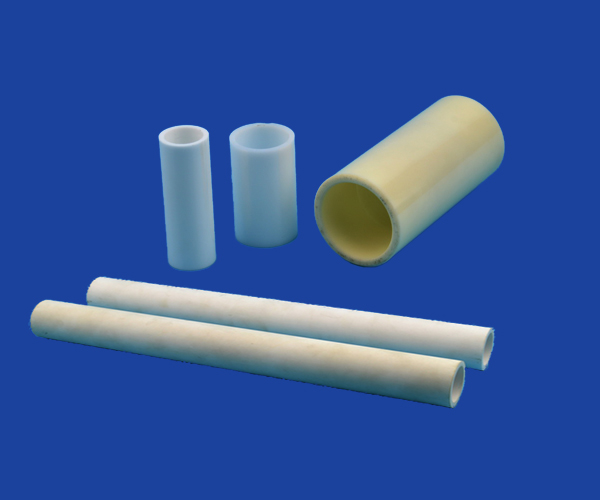

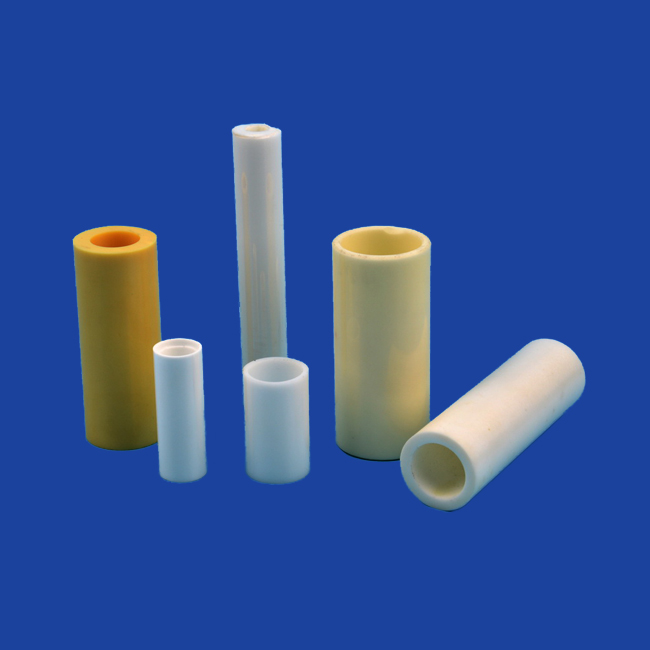

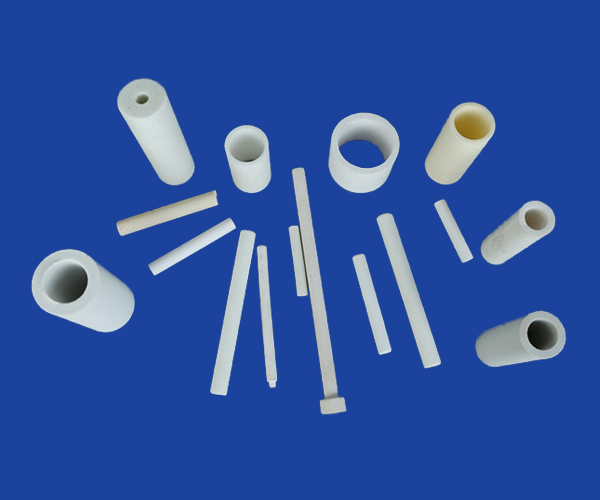

Sizes and types

Application

Machining

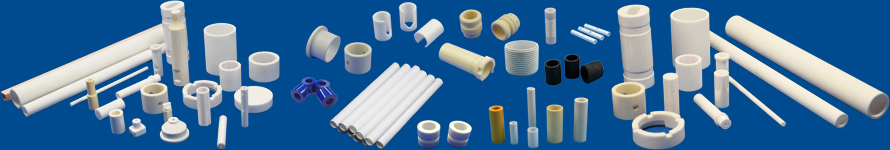

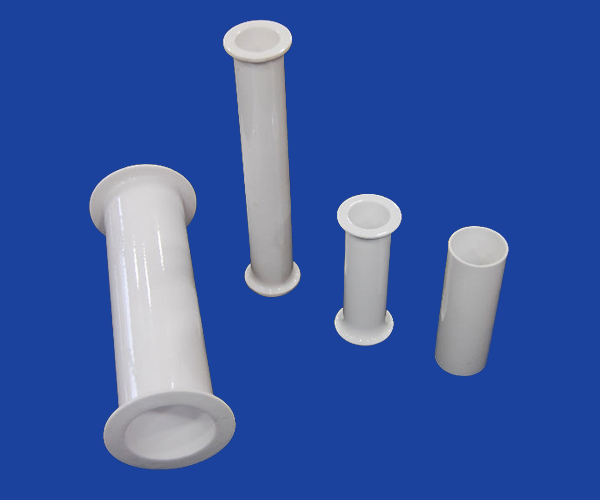

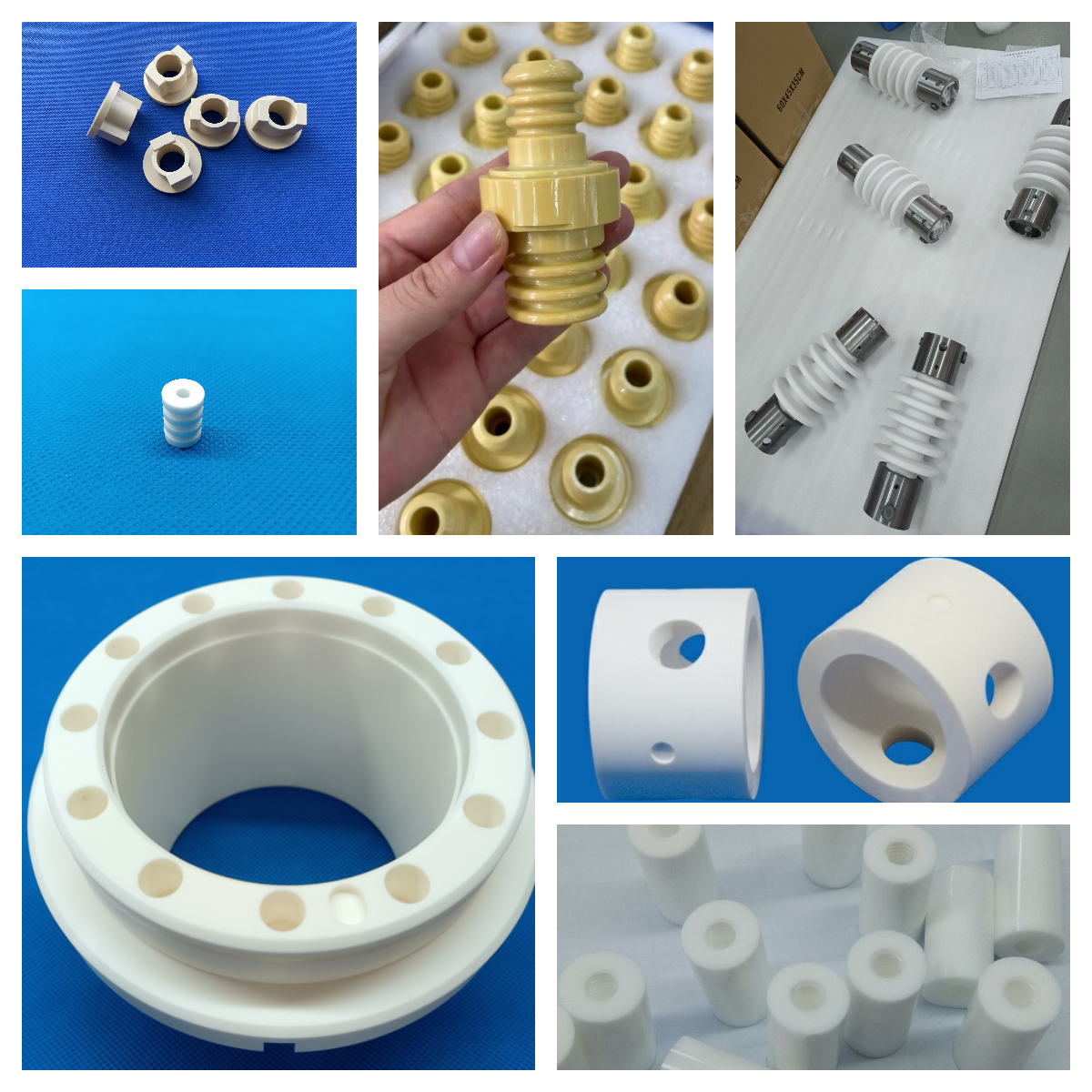

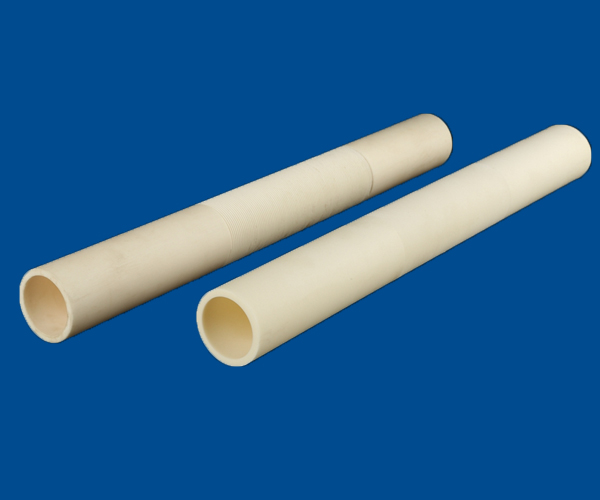

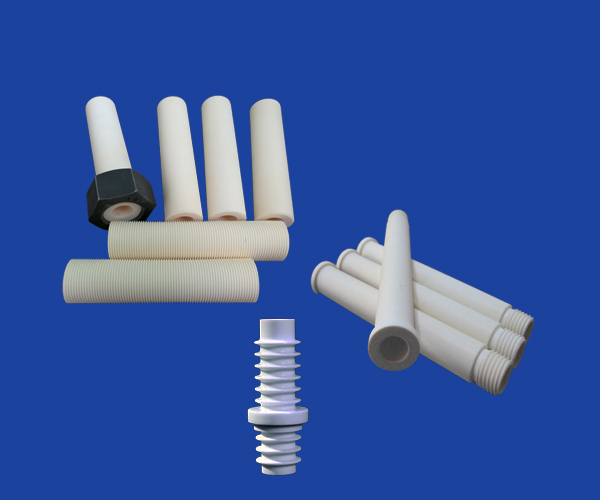

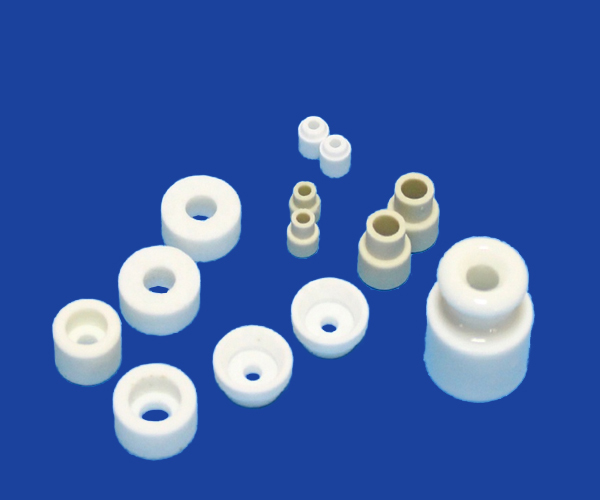

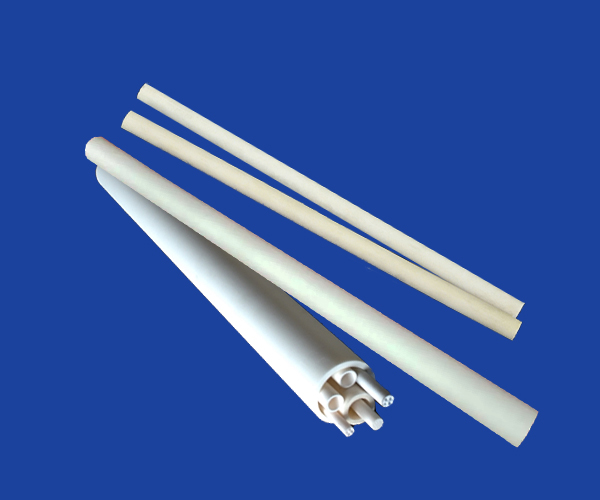

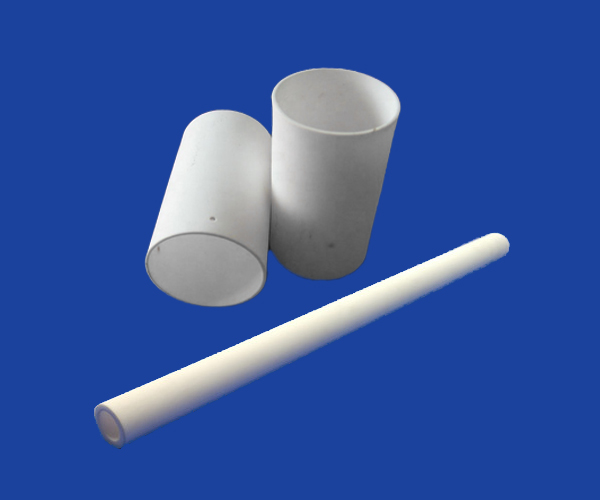

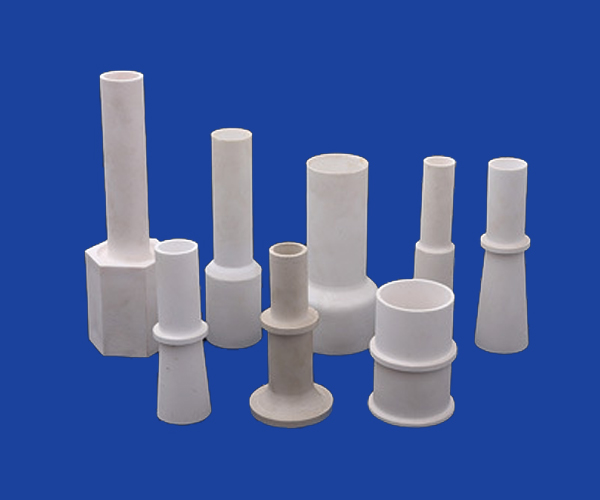

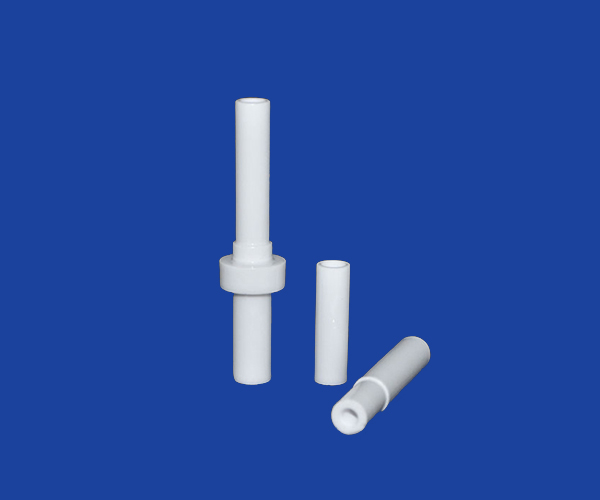

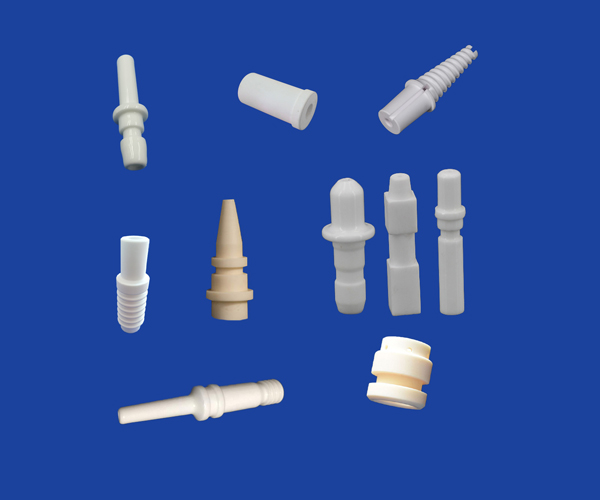

As a pro ceramic tube manufacturer, Us produce and sell multi sizes or shapes tube types ceramic products for our customer with factory price fast shipping, and offer customized service(Manufactured according to customer requirements).

The ceramic materials we use:95%--99.99%Alumina (Al2O3)/ Zirconia(ZrO2:TTZ,YTZP, ZDY) /Si3N4 /SiC...

Delivery times:2 -25 days(depends on the quantity) Factory price and shipment within 24 hours In stocks...

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)...

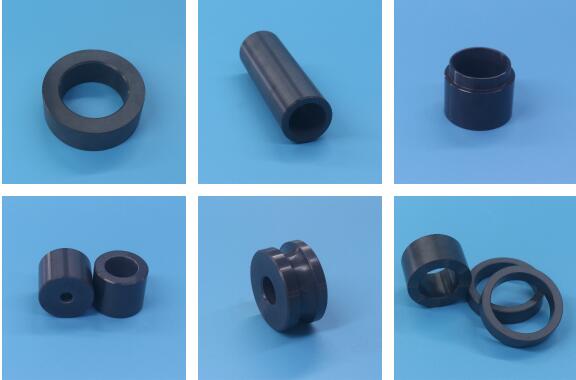

2. Hardness Strength, Wear Resistance Up To Mohz 9.0 ; HRA 80-90...

3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, MAX 10 MPa.m1/2 Fracture toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance...

8. Long Service Life...

9. Other excellent property

>More ceramics tube property

>More ceramic tube process

| Thermocouple protection tube | Furnace tube | Pump body tube | Bushing tube |

| Insulated tube | Heating tube | Inner liner tube | Roller tube |

| Inner core | Radiant tubes | Round tube | Single / mutli holes tube |

| automotive, aviation, space travel | laboratory technology |

| electrical and thermal insulation | laser technology |

| electronics and sensors | mechanical and chemical process engineering |

| energy technology, power generation | metal industry |

| environmental technology | optics |

| fluid technology | semiconductor processing equipment |

| friction-reduction, wear- and corrosion -protection | surface treatment |

| high temperature applications | vacuum technology |

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS