Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730

Alumina ceramic (Al2O3) -- Aluminium oxide ceramics |

|

|

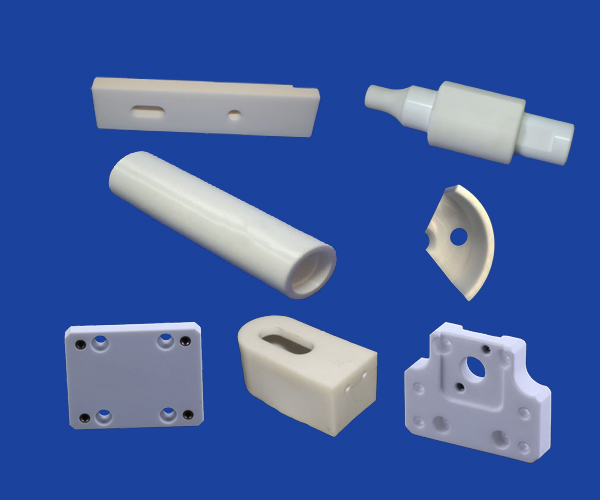

Alumina ceramic, Al2O3 aluminium oxide ceramics is an advance ceramic materials which used for the industry.It has excellent material properties over metal. Aluminum oxide ceramics is very hard and resistant to wear, providing high compressive strength even in extreme temperatures and corrosive environments.Alumina is also an excellent electrical insulator and gas tight. Typical Alumina property include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties (from DC to GHz frequencies) Low dielectric constant Low loss tangent Others |

|

Alumina ceramic composition(Al2O3 purity 95% to 99.99%):

High purity alumina ceramics

99.99% Alumina ceramic; 99.9% Alumina ceramic,

Ordinary alumina ceramics

99.7% Alumina ceramic,99.5% Alumina ceramic,99% Alumina ceramic,97% Alumina ceramic,96% Alumina ceramic,95% Alumina ceramic

Note: different industries, different environments, different equipment, different products have different requirements on the composition of alumina, different alumina ceramic components have different performance and service life.

| Properties | Unit | Alumina (AL2O3) | |||

| AL2O3≥95 | AL2O3≥99 | AL2O3≥99.5 | AL2O3≥99.8 | ||

| Volumetric density | g/cm3 | 3.7 | 3.80-3.85 | 3.85 | 3.9 |

| Hardness | HRA≥ | 86 | 88 | 88 | 88 |

| Flexural Strength | Mpa≥ | 300 | 350 | 400 | 400 |

| Maximum temperature | ℃ | 1500 | 1500 | 1500 | 1500 |

| Line expansion coefficient | ×10-6/℃ | 7.5 | 8.2 | 8.2 | 8.2 |

| Dielectric constant | εr(20℃,1MHz) | 9 | 9.2 | 9.2 | 9.2 |

| Media loss | tanδ×10-4,1MHz | 3 | 2 | 2 | 2 |

| Volumetric resistivity | Ω·cm(20℃) | 1013 | 1014 | 1014 | 1014 |

| Breakdown strength | KV/mm,DC≥ | 20 | 20 | 20 | 20 |

| Acidic resistance | mg/cm2≤ | 0.7 | 0.7 | 0.7 | 0.7 |

| Alkaline resistance | mg/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Abrasion resistance | g/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Compressive strength | Mpa≥ | 2500 | 2500 | 2500 | 2800 |

| Flexural Strength | Mpa≥ | 200 | 350 | 350 | 350 |

| Thermalcoefficient | W/m·K(20℃) | 20 | 25 | 25 | 25 |

|

Properties of Alumina/Aluminum Oxide (Al2O3) 1.Very good electrical insulation (1x10^14 to 1x10^15 Ωcm) 2.Moderate to extremely high mechanical strength (300 to 630 MPa) 3.Very high compressive strength (2,000 to 4,000 MPa) 4.High hardness (15 to 19 GPa) 5.Moderate thermal conductivity (20 to 30 W/mK) 6.High corrosion and wear resistance 7.Good gliding properties 8.Low density (3.75 to 3.9 g/cm3) 9.Operating temperature without mechanical load 1,000 to 1,500°C. 10.Bioinert and food compatible |

The composition types of Alumina ceramicAlumina(Al2O3)95%; 97%; 98%; 99%; 99.5%: 99.7%; 99.8%; 99.9%; 99.99%... Catalyst support:Alumina Al2O3 has been used as the carrier of platinum, palladium, cobalt, manganese, iron, nickel, vanadium and other compounds, forming oxidation-reduction and acid-base catalysis. |

Ceramic manufactures OEM ceramic components and enjoys on-going relationships with businesses of all sizes in dozens of industries, in addition to the markets showcased at the top of this page, including:

|

Products and Aplications – Pieces, Plates, Boards, Trays, etc. in Alumina-Ceramic / Cordierite-Mullite – Tubes, Rods, Rollers, Supports, etc. in Alumina-Ceramic / Cordierite-Mullite – Protection, Thermocouples, Insulation, etc. in Alumina-Ceramic / Cordierite-Mullite – Pieces, Plates, Tubes, Rods, Rollers, etc. in Zirconium Oxide – others |

User industries

automotive, aviation, space travel

electrical and thermal insulation electronics and sensors energy technology, power generation environmental technology fluid technology friction-reduction, wear- and corrosion -protection high temperature applications laboratory technology laser technology mechanical and chemical process engineering metal industry optics semiconductor processing equipment surface treatment vacuum technology |

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve