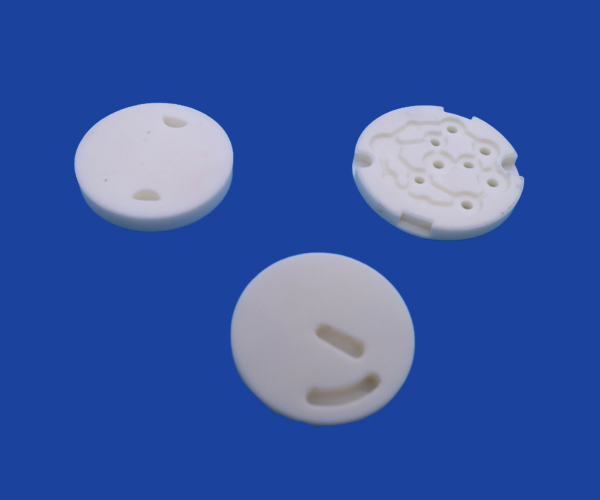

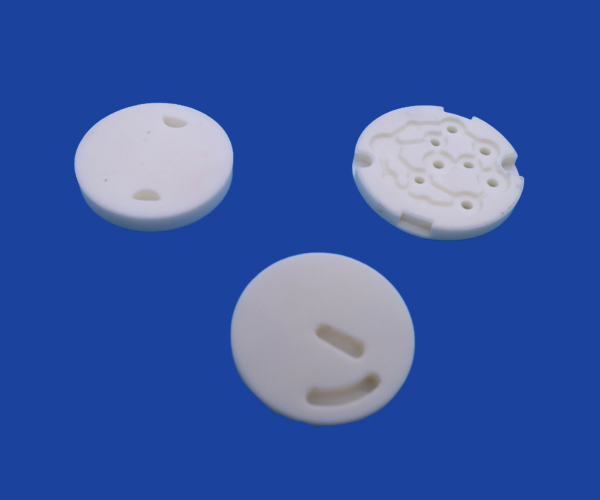

Alumina Ceramic Multihole Round Plate Precision Machined Zirconia Ceramic Discs

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Max Length/width:450mmThickness:0.2mm...

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

- Customized:Alumina Multihole Ceramic Round Plate

Can be customized for special sizes and shapes

1. Lead time: Factory price and shipment within 24 hours if parts in stocks

2. MOQ:1pc

3. Payment Term: PayPal; T/T; L/C etc.

4. Shipment: by sea / by air / by express

Alumina Ceramic Multihole Round Plate High temperature and wear resistant High Precision Machined Zirconia Ceramic Discs

Product name: alumina ceramic parts

Material: Al2O3-99.7% imported from Germany

Origin of raw materials: Germany

Shape: according to the drawing requirements

Heat resistance: 1600 ~ 1800 ℃

Application: widely used to meet the needs of daily use and special performance

Features: high hardness, good wear resistance, light weight

Whether to process custom: yes

Product characteristics:

the higher the purity of Al2O3, its high temperature strength, electrical insulation performance, wear resistance performance is better, in oxidizing or reducing atmosphere, can also be used to a very high temperature.Alumina has a high hardness and density, English hardness is 9, slightly lower than diamond, volume density is generally greater than 3.5g/m³, some up to 4.0g/m³.Alumina ceramics according to Al 2O 3 content is divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain and other varieties, 99 alumina ceramic materials for the production of high temperature crucible, furnace tube and special wear-resistant materials, such as ceramic bearings, ceramic seals;95 alumina ceramics are mainly used for corrosion resistance and wear resistance parts.

Application fields of alumina ceramic discs

Due to their excellent physical and chemical properties, alumina ceramic discs have a wide range of application scenarios in multiple fields. The following are some of the main application scenarios:

1. Mechanical and industrial processing:

Alumina ceramic discs are often used as mechanical parts such as bearings, sealing rings and wear-resistant plates due to their high hardness and wear resistance.

In the process of grinding and polishing, alumina ceramic discs can be used as grinding wheels, grinding discs or polishing pads for precision machining of materials such as metals, ceramics, and glass.

2. Electronics and electrical:

Due to their good insulation properties and high-temperature stability, alumina ceramic discs are widely used in electronic components such as electronic packaging, substrates, insulators, etc.

In the power industry, alumina ceramic discs can be used as insulating components of high-voltage switches to ensure the safe operation of power equipment.

3. Chemical and environmental protection:

Alumina ceramic discs are used to manufacture corrosion-resistant components in chemical equipment, such as pipes, valves, pump bodies, etc. due to their excellent corrosion resistance.

In the field of environmental protection, alumina ceramic discs can be used to treat corrosive wastewater and exhaust gas and protect equipment from corrosion.

4. Medical and Biological:

Alumina ceramics are widely used in the medical field due to their biocompatibility and chemical stability. Although the disc shape may not be directly used for human implants, alumina ceramic materials can be used to manufacture parts of medical devices, such as scalpels, bone screws, etc.

In the dental field, alumina ceramics can be used to make dental restoration materials, such as crowns and bridges.

5. Aerospace:

Alumina ceramic discs have potential applications in the aerospace field due to their high temperature stability and light weight and high strength. Although the specific shape may vary depending on the application, alumina ceramic materials can be used to manufacture engine parts, thermal protection systems, etc.

6. Optics and Lasers:

In the field of optics, alumina ceramic discs can be used as substrate materials for optical components such as reflectors and lenses. Due to their high flatness and low thermal expansion coefficient, they are conducive to maintaining the stability of the optical system.

In laser technology, alumina ceramic discs can be used as heat sinks or optical isolation elements for lasers.

7. Semiconductors and microelectronics:

In the semiconductor manufacturing process, alumina ceramic discs can be used as fixed rings or other precision parts of photolithography machines to ensure the stability and accuracy of the manufacturing process.

8. Beauty and health care:

In beauty instruments, alumina ceramic discs can be used as heating elements of radio frequency beauty instruments, using their good thermal conductivity and stability to achieve uniform heating and deep care.

Delivery:

Custom OEM will be shipped within 15 days after determining the parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the ceramic plates, please contact us or email:admin@cerampart.com

Machining process

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

Mingrui ceramic parts property

|

· Flexural strength |

· Chemical resistance |

· Electrical insulation |

· Corrosion resistance |

· Dielectric strength |

|

· Wear resistance |

· Temperature resistance |

· Thermal conductivity |

· High voltage |

· Hardness... |

Ceramic materials(include but not limited belows)

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

Al 2O 3 |

ZrO2/Y2O3 |

ZrO2/MgO |

MgO |

SiC |

Si3N4 Reaction sintered |

Si3N4 Hot pressed |

ALN |

|

Physical properties |

|

|

|

|

|

|

|

|

|

Density (g/cm3) |

3,9 |

5,9 |

5,75 |

3,58 |

3,2 |

3,27 |

3,29 |

3,26 |

|

Molecular weight (g/mole) |

102 |

- |

- |

40,4 |

40,1 |

140 |

140 |

41 |

|

Maximum service temperature air (°C) |

1700- 1800 |

1500 |

1000 |

2200 |

1500 |

1200- 1500 |

1100- 1600 |

1000- 1800 |

|

Mechanical properties |

|

|

|

|

|

|

|

|

|

Hardness (Mohs) |

9 |

- |

- |

5,5 |

9 |

- |

- |

7 |

|

Modulus of elasticity (GPa) |

300-400 |

200 |

200 |

250-300 |

420 |

170-220 |

280-310 |

318 |

|

Poisson's ratio |

0,25 |

- |

- |

0,18 |

0,14 |

0,25-0,26 |

0,27 |

0,25 |

|

Fracture toughness (MPa.m1/2) |

2-3 |

7-13 |

6-10 |

- |

2,5-3,5 |

3,5-5 |

6,1 |

4,5 |

|

Electrical properties |

|

|

|

|

|

|

|

|

|

Dielectric constant |

9-10 |

- |

- |

9-10 |

- |

10 |

10 |

9,2 |

|

Electrical resistivity at 20°C (Ohm.cm) |

>10 14 |

10 13-10 14 |

>10 10 |

- |

10 2-10 6 |

>10 7 |

10 12- 10 15 |

>10 14 |

|

Dielectric strength (kV/mm) |

10-20 |

9 |

2-10 |

- |

- |

- |

- |

15 |

|

Thermal properties |

|

|

|

|

|

|

|

|

|

Specific heat (J/K/kg) |

900 |

400-500 |

420 |

870-880 |

750 |

690 |

680-800 |

800 |

|

Thermal conductivity (W/m/K) at 20°C |

26-35 |

2,2-3,2 |

1,5-2,5 |

40-50 |

63-155 |

9-30 |

15-43 |

180 |

|

Coefficient of thermal expansion ( 10-6) from 20 to 1000°C |

8-9 |

10-11 |

5-16 |

10-13 |

4-5 |

3 |

3,3 |

4,4-5,3 |

|

Melting point (°C) |

2050 |

2590 |

- |

2800 |

2500 |

1900 |

1900 |

2200 |

Customization & Machining Service:

As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL.

Our Custom Capabilities:

1.High Purity Martoxid Powder

2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience

3.35000 ㎡workshop, annual output could reach hundred million pieces.

4.All crafts are inspected strictly based on drawings,checked each month.

5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

|

|

|

Technical reference of manufacture |

|

Dimensional accuracy |

Up to 0.001mm |

|

Concentricity |

Up to 0.003mm |

|

Parallelism |

Up to 0.002mm |

|

The inner hole tolerance |

The minimum 0.005mm |

|

Straight flute |

The narrowest 0.1x100mm |

|

The thickness of the size |

Minimum to 0.02mm |

|

The screw thread |

Minimum internal thread M2 |

|

Cylindricity |

Up to 0.004mm |

|

The linear tolerance |

Up to 0.001mm |

|

The smallest aperture |

The minimum 0.07mm |

|

Precision process |

CNC maching,grinding,lapping |

|

Surface finish |

Glazed,polishing or metallized

|

|

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730