Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730

|

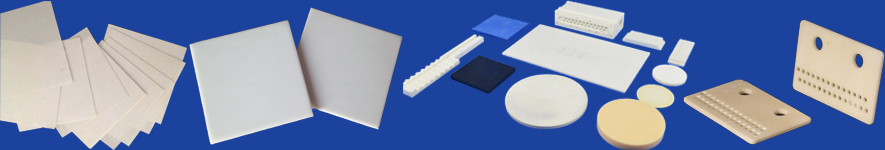

Ceramic plate materials: 1. Alumina ceramic(Al2O3): 95%;96%;97%;98%;99%;99.5%:99.7%;99.9% 2. Zirconia ceramic(Zro2): TTZ: Magnesia Partially Stabilized Zirconia (Zro2) YTZP: Yttria Partially Stabilized Zirconia (Zro2) ZDY: Yttria Fully Stabilized Zirconia (Zro2) 3. Silicon Carbide 4. Silicon Nitride 5. And others Size: Maximum length as 450mm; Thinnest thickness as 0.02mm; Widest width as 450mm... Shape: Rectangle, square, circle, semicircle, irregular, customizable.. |

Ceramic Specifications:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)... 2. Hardness Strength, Wear Resistance Up To Mohz 9.0 Levels... 3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm... 4. High Polished Surface Up To Rz0.8(Ra0.1) ... 5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness, 6. Pressure Resistance, Max 2300MPa compressive strength... 7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance... 8. High thermal conductivity 9. Other excellent property... |

| alumina ceramic plates | alumina ceramic sheets | alumina ceramic substrates |

| zirconia ceramic plates | zirconia ceramic sheets | zirconia ceramic substrates |

| Silicon Carbide plates | Silicon Carbide sheets | Silicon Carbide substrates |

| Silicon Nitride plates | Silicon Nitride sheets | Silicon Nitride substrates |

|

The best-selling sizes are as follows in stock: Alumina ceramic plates series: |

| 200mm(7.86in) | 200mm(7.86in) | 10mm(0.39in) | Get the latest price | contact us :admin@cerampart.com |

| 400mm(15.72in) | 135mm(5.31in) | 9mm(0.35in) | Get the latest price | contact us :admin@cerampart.com |

| 153mm(6.01in) | 100mm(3.93) | 5mm(0.20in) | Get the latest price | contact us :admin@cerampart.com |

| 120mm(4.72in) | 90mm(3.54in) | 19mm(0.75in) | Get the latest price | contact us :admin@cerampart.com |

| 80mm(3.14in) | 60mm(2.36in) | 0.1mm(0.004in) | Get the latest price | contact us :admin@cerampart.com |

| 90mm(3.54in) | 65mm(2.55in) | 0.8mm(0.03) | Get the latest price | contact us :admin@cerampart.com |

| 115mm(4.52in) | 75mm(2.95in) | 0.4mm(0.02) | Get the latest price | contact us :admin@cerampart.com |

|

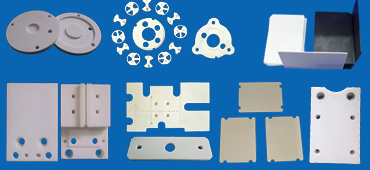

Customization and machining: We can produce different sizes and shapes of the ceramic plates sheets series for specific applications to different custom products.Such as drilling, polishing, stripes, concave and convex, screw holes, metal parts position and so on. Typical applications: LED packages, power modules, chip resistors,heat dissipation, thermal printer head, automotive parts, sgeneral thick film application, sensor parts, electronic devices...etc |

|

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS