The advantages of using advanced ceramic materials in ceramic substrates are significant, mainly reflected in thermal conductivity, mechanical properties, electrical properties, chemical stability, and matching with chip materials. These advantages make them ideal for high-power, high-frequency, and high-reliability electronic device packaging.

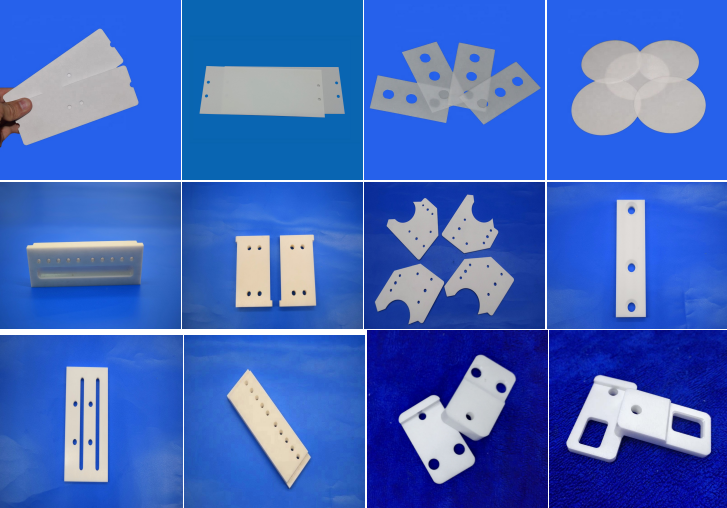

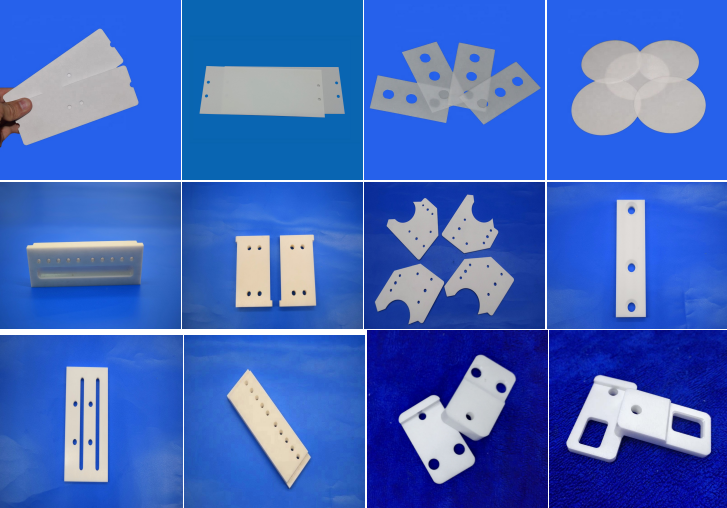

Some ceramic substrates produced by Mingrui Ceramics

The following lists the advantages of using advanced ceramic materials in ceramic substrates.

1. High thermal conductivity

· Advantages: Advanced ceramic materials such as aluminum nitride (AlN), silicon nitride (Si₃N₄), and silicon carbide (SiC) have excellent thermal conductivity, which can effectively dissipate heat, reduce device operating temperature, and improve device reliability and life.

· Application scenarios: In high-power electronic devices (such as LEDs, power modules, IGBTs, etc.), ceramic substrates with high thermal conductivity can quickly conduct heat away to prevent the device from failing due to overheating.

2. Excellent mechanical properties

· Advantages: Advanced ceramic materials have high hardness, high strength and good wear resistance, can withstand large mechanical and thermal stresses, and ensure the long-term stability of the substrate.

· Application scenarios: In applications that require high reliability (such as aerospace, automotive electronics, etc.), the mechanical properties of ceramic substrates can ensure that the device works normally in harsh environments.

3. Good electrical properties

· Advantages: Advanced ceramic materials have high insulation resistance, low dielectric constant and low dielectric loss, which can effectively reduce energy loss and interference during signal transmission and improve the electrical performance of the device.

· Application scenarios: In high-frequency electronic devices (such as radio frequency devices, microwave devices, etc.), the electrical properties of ceramic substrates can ensure efficient signal transmission.

4. Excellent chemical stability

· Advantages: Advanced ceramic materials have good corrosion resistance and chemical stability, can be used for a long time in high temperature, high humidity or corrosive environment, and are not prone to chemical reactions or degradation.

· Application scenarios: In the fields of chemical, medical, aerospace, etc., the chemical stability of ceramic substrates can ensure the reliability of devices in harsh environments.

5. Matching the thermal expansion coefficient with chip materials

· Advantages: The thermal expansion coefficient of advanced ceramic materials is similar to that of semiconductor chip materials (such as silicon), which can effectively reduce the thermal stress caused by mismatched thermal expansion coefficients and reduce the risk of device failure.

· Application scenarios: In integrated circuit packaging, matching the thermal expansion coefficients of ceramic substrates and chips can improve the reliability and life of the packaging.

6. High temperature stability

· Advantages: Advanced ceramic materials have excellent high temperature stability, can maintain their physical and chemical properties unchanged in high temperature environments, and are suitable for high temperature application scenarios.

· Application scenarios: In high temperature electronic devices (such as automotive engine control units, aerospace electronic equipment, etc.), the high temperature stability of ceramic substrates can ensure the reliability of devices at extreme temperatures.

7. Lightweight

· Advantages: Compared with metal substrates, ceramic substrates have lower density, which can achieve lightweight design of devices and are suitable for weight-sensitive applications (such as aerospace, portable electronic devices, etc.).

8. Design flexibility

· Advantages: Advanced ceramic materials can be processed through a variety of processes (such as thick film printing, thin film deposition, direct copper coating, etc.), which can achieve complex multi-layer structures and fine circuits to meet high-density integration requirements.

· Application scenarios: In miniaturized and highly integrated electronic devices, the design flexibility of ceramic substrates can meet complex packaging requirements.

Although the cost of advanced ceramic substrates is generally higher than that of organic or metal substrates, the irreplaceable value they bring in high-performance, high-reliability and extreme environment applications makes them the cornerstone material in these key areas. With the rapid development of 5G/6G communications, electric vehicles, renewable energy, high-end computing and industrial automation, the demand for advanced ceramic substrates will continue to grow.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730