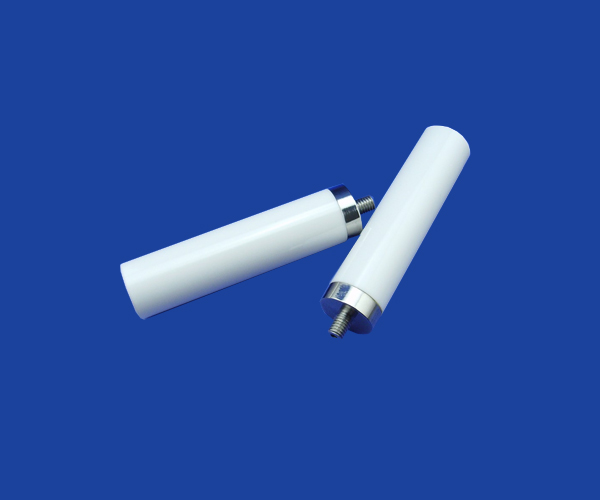

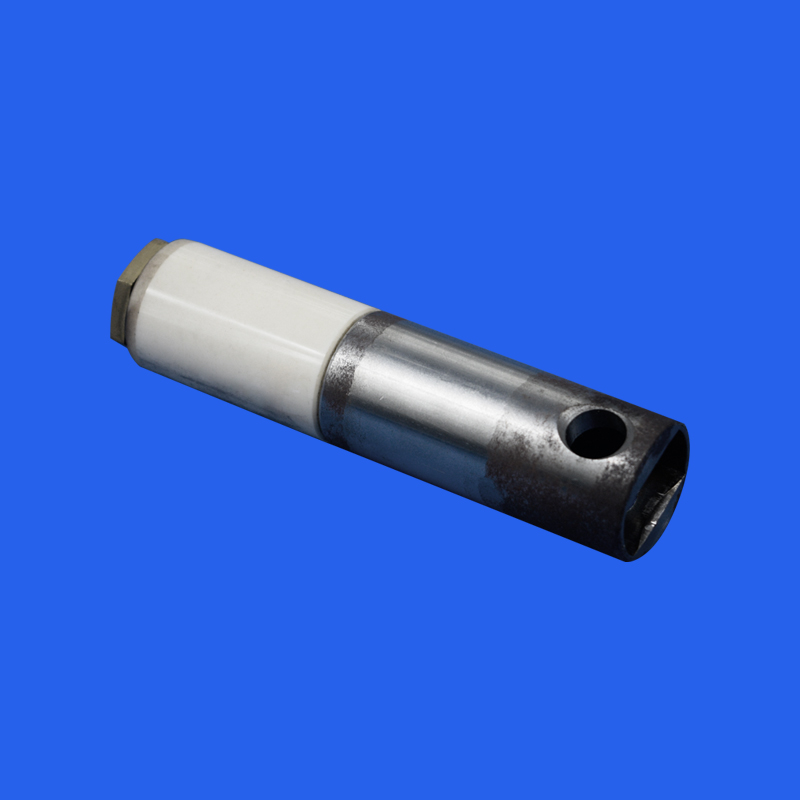

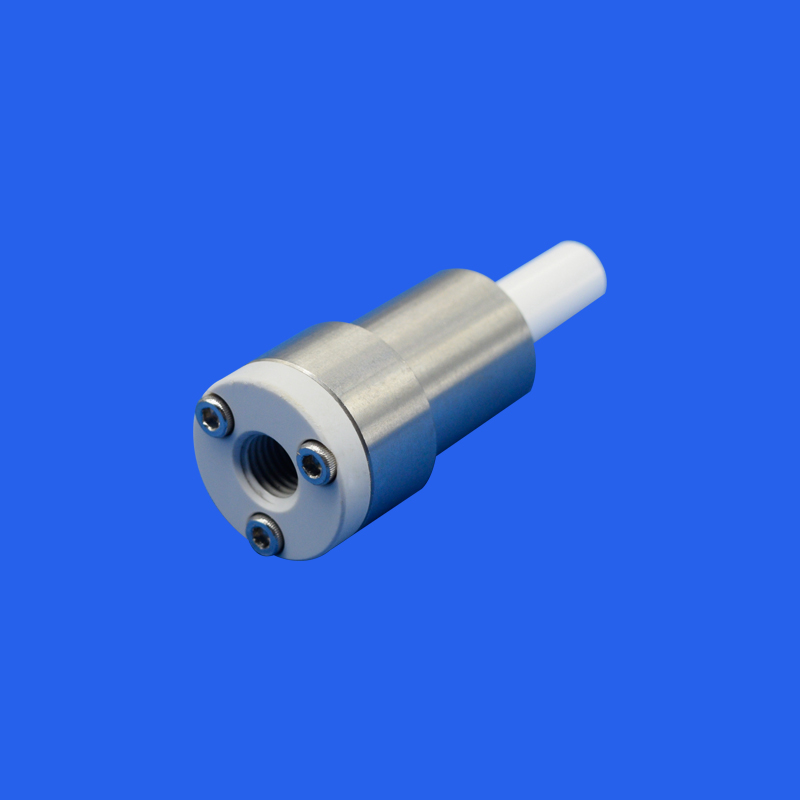

Ceramic pump |

|

|

| Ceramics is a advance material with excellent corrosion and wear resistance, ceramic pump is a reference to this performance, pump body and pump cover using acid-resistant ceramics manufacturing. Ceramic pump for chemical industry is generally centrifugal pump, its impeller, worm shell, shaft sealing cavity and suction,and discharge pipe are made of ceramics. |

|

|

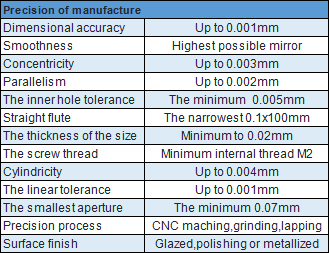

Material standard: High density, Superior roughness, High HV hardness, Never rusting Ceramic advantage: Ceramic meets above all performance standard, never rusting. Lead-time: 20-30 days for mass production, 7-15 days for samples. |

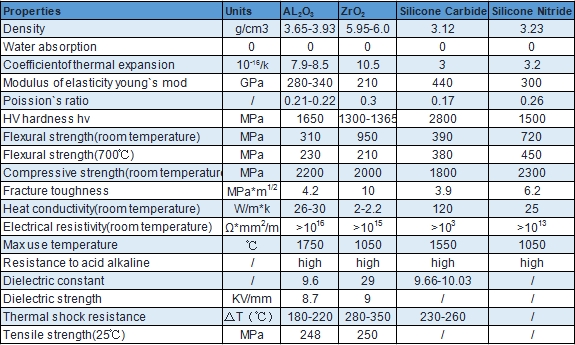

Ceramic materials:

· Alumina ceramic(AL2O3)

· Zirconia ceramic(ZrO2)

· Silicone carbide (SiC)

· Silicone nitride

|

|

|

| For more information about ceramics,please contact our engineers in time |

|

Dynamic information Ceramic technology FAQ Ceramice exhibition

Ceramics quality Ceramics technical Ceramice after-sale Customer witness Patent certificate

Ceramic flange Ceramic bushing Ceramic plunger Ceramic pump valve