Difference between solid diffusion welding and brazing of zirconia ceramics

Time: 2018-12-08 Writer: mingrui

Difference between solid diffusion welding and brazing of zirconia ceramics

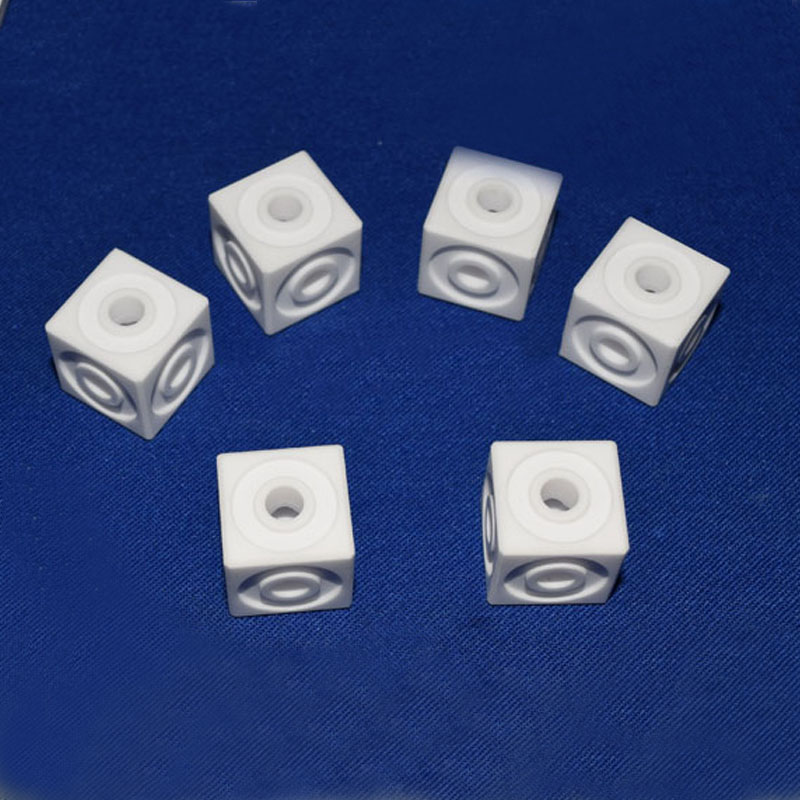

Zirconia ceramics is a new kind of high composite material, which is widely used in structural ceramics.

Firstly, it is indicated that fusion welding is not suitable for the welding of zirconia ceramic structure parts.Solid phase diffusion welding and brazing are more suitable for the welding of products and have been applied. The specific solid phase diffusion welding and brazing are compared as follows:

In addition to the active filler metal method, brazing ceramics also have a method of surface metallization of zirconia ceramic structural parts which is used in conjunction with conventional filler metal.Its disadvantage is that the process is rather complicated.The biggest advantage of solid phase diffusion welding is to avoid the wetting of zirconia ceramic structure parts by metal.However, it requires that the whole welding interface must keep close contact, so the machining accuracy of the interface is very high, which is not suitable for the welding of large area and complex boundary.

Brazing is mainly restricted by wettability, but it requires less precision of welding surface and is suitable for welding of large area and complex interface.in addition to diffusion welding, there are also friction welding and microwave welding in the solid phase welding method of zirconia ceramic structure parts, but these methods are not mature, and there are many shortcomings.Microwave welding is not suitable for free and metal welding because it USES the microwave absorption characteristics of zirconia ceramic structural parts to heat and diffuse connection.

There are some problems in the welding of zirconia ceramic structure parts with metal or with metal filler materials.Want to choose different welding way according to specific circumstance so, just can reflect the beautiful degree that gives a product so.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730