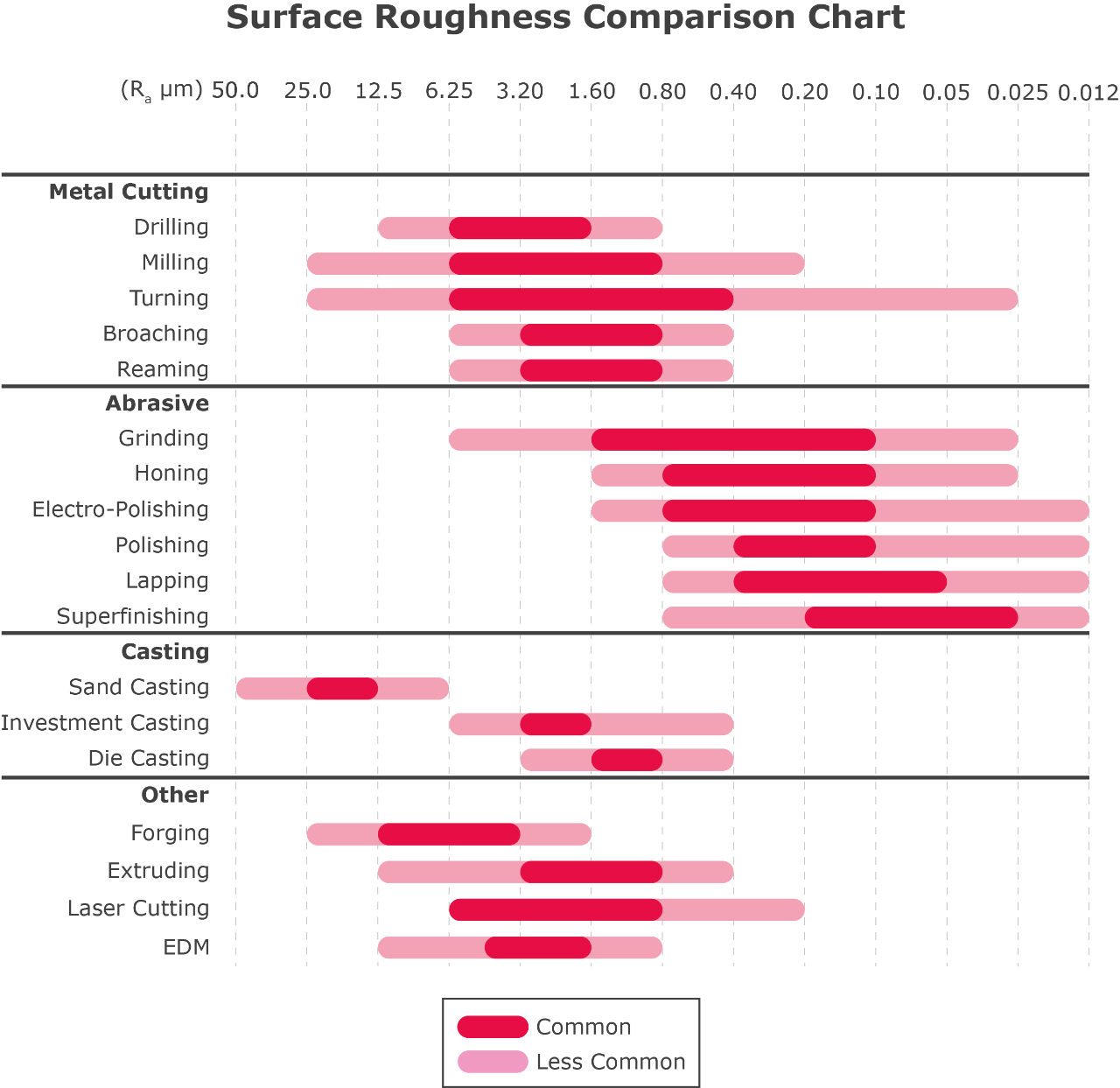

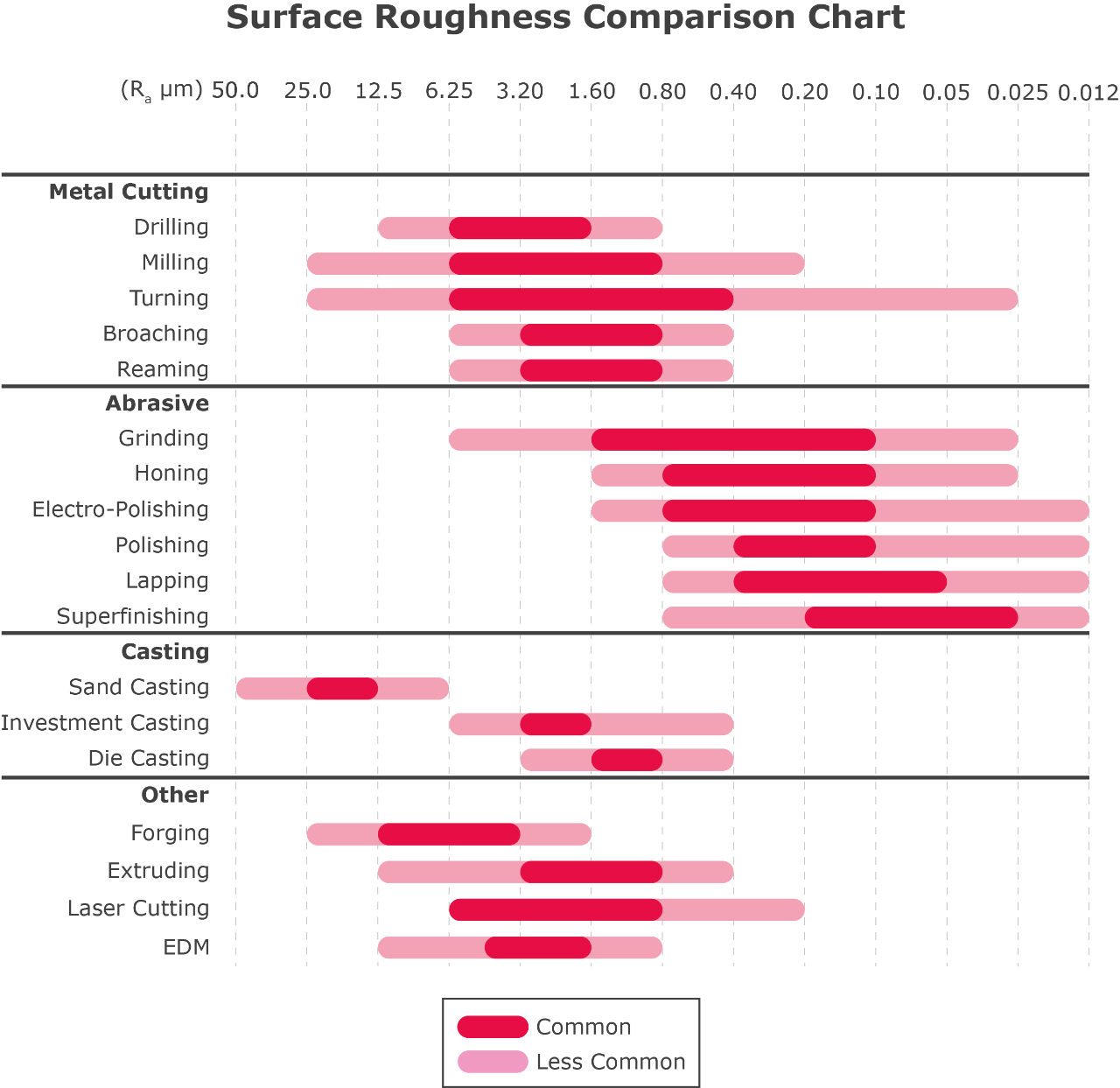

Roughness generally refers to surface roughness. Surface roughness refers to the unevenness of a machined surface, characterized by small gaps and tiny peaks and valleys. The smaller the surface roughness, the smoother the surface. The number Ra embodies the stringent requirements of manufacturing engineers for surface quality.

Why is surface roughness so important for industrial ceramic parts?

1. It provides a certain visual appearance and tactile feel.

2. It affects fatigue strength. The fatigue life of a component decreases with increasing surface roughness, especially under high-cycle fatigue conditions.

3. Cleaning. Greater roughness can cause dirt to adhere to the recesses of metal, making cleaning more difficult. Conversely, smooth surfaces are easier to clean due to their smooth contours.

4. Wear. Rough surfaces wear more easily and have greater friction; a high coefficient of friction means that greater force is required for sliding compared to smooth surfaces. Roughness is also crucial for corrosion and chemical resistance, as defects provide nucleation sites for fracture or corrosion.

5. Sealing. When two surfaces move in close contact with each other, roughness will affect their sealing or wear performance.

Therefore, the microscopic roughness Ra value has become a key technical indicator in manufacturing.

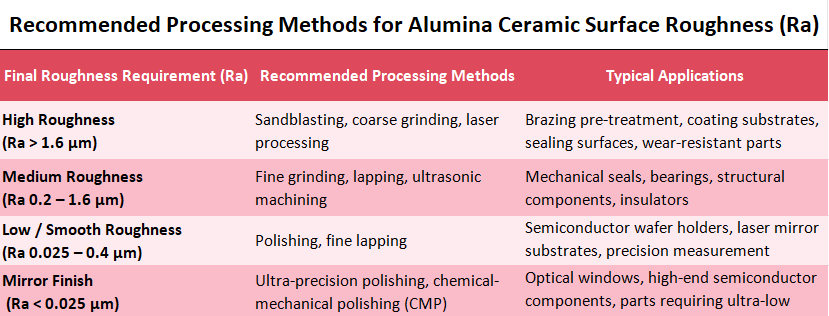

Alumina ceramics are not ordinary materials; they have considerable hardness. To improve product precision, most alumina materials undergo further finishing after sintering. Due to the excellent properties of alumina ceramics, harder abrasive and polishing materials are needed for finishing, such as SiC, B4C, or diamond. Furthermore, the surface lubricity of the alumina ceramic material must be improved beforehand during finishing. A common method for finishing alumina ceramics is to grind with progressively finer abrasives, followed by surface polishing. For polishing, Al2O3 micropowder smaller than 1µm or full-diameter diamond can be used. Of course, laser processing and ultrasonic processing can also achieve the same grinding and polishing results for alumina ceramics.

From rough to fine: The typical machining path for an alumina ceramic part (such as a mechanical seal ring) might be: Blank (after sintering) → Rough grinding (shaping, Ra~0.8μm) → Fine grinding (achieving dimensions, Ra~0.2μm) → Grinding (improving flatness, Ra~0.05μm) → Polishing (Ra≤0.02μm)

The surface roughness of alumina ceramics has a significant impact on the performance of the parts. Generally speaking, a lower surface roughness value improves the fit quality, reduces wear, and extends the service life of the parts, but it increases the machining cost of alumina ceramics. Therefore, it is crucial to select the correct and reasonable surface roughness value. When designing parts, the choice of surface roughness value is determined by the part's function within the machine.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730