Silicon carbide ceramic tubes are a high-performance ceramic material pipe, mainly made of silicon carbide (SiC) powder through molding, sintering and other processes.

The following is a detailed introduction to silicon carbide ceramic tubes:

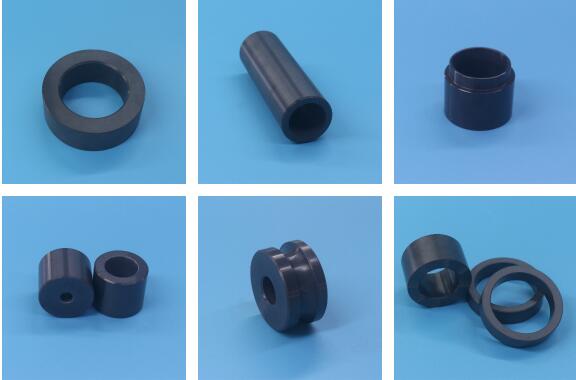

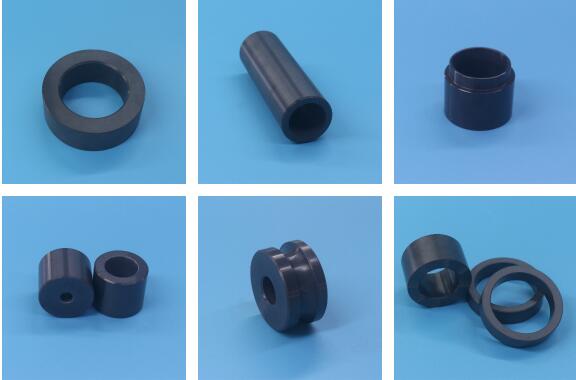

Silicon carbide ceramic tubes produced by Mingrui Ceramics

1. Material properties of silicon carbide ceramic tubes

High hardness and high strength: The hardness of silicon carbide ceramic tubes is very high, second only to diamond and boron nitride, which makes it highly wear-resistant and scratch-resistant. At the same time, its strength is also high and can withstand greater pressure and load.

High temperature resistance: Silicon carbide ceramic tubes have excellent high temperature resistance and can maintain stable physical and chemical properties in high temperature environments. This makes it widely used in high temperature equipment such as high temperature furnaces and heat exchangers.

Corrosion resistance: Silicon carbide ceramic tubes have good corrosion resistance to a variety of acids, alkalis and organic solvents, and can be used for a long time in harsh chemical environments without being corroded.

Good thermal conductivity: Silicon carbide ceramic tubes have good thermal conductivity and can quickly transfer heat, making them advantageous in heat conduction and heat exchange.

2. Manufacturing process of silicon carbide ceramic tubes

The manufacturing process of silicon carbide ceramic tubes mainly includes steps such as raw material preparation, molding, sintering and post-processing.

Raw material preparation: Select high-purity silicon carbide powder as the raw material, and add an appropriate amount of sintering aid to improve sintering performance and density.

Molding: After mixing the silicon carbide powder and the sintering aid evenly, the ceramic tube of the desired shape is made by pressing, grouting or injection molding.

Sintering: The formed ceramic tube is sintered at high temperature to form a close bond between the silicon carbide particles, thereby improving the strength and density of the ceramic tube.

Post-processing: The sintered ceramic tube is subjected to post-processing processes such as cutting, grinding, and polishing to meet the use requirements.

3. Application fields of silicon carbide ceramic tubes

Silicon carbide ceramic tubes have been widely used in many fields due to their excellent performance:

High-temperature furnaces: In high-temperature equipment such as electric furnaces and gas furnaces, silicon carbide ceramic tubes are used as furnace tubes, furnace linings and other components, which can withstand the test of high temperature and corrosive environment.

Heat exchanger: In the chemical, petroleum, metallurgical and other industries, silicon carbide ceramic tubes are used as heat transfer elements of heat exchangers to improve heat exchange efficiency and service life.

Corrosion-resistant pipelines: In pipeline systems that transport corrosive media, silicon carbide ceramic tubes are used as corrosion-resistant pipelines to protect the system from corrosion.

Other fields: Silicon carbide ceramic tubes are also widely used in aerospace, medical equipment, electronic components and other fields as high-temperature structural parts, corrosion-resistant parts, etc.

4. Precautions of silicon carbide ceramic tubes

Installation and maintenance: When installing silicon carbide ceramic tubes, ensure that the pipes are tightly connected and fixed reliably. During use, the pipes should be regularly checked for cracks, wear and other damage, and repaired or replaced in time.

Use environment: Although silicon carbide ceramic tubes have excellent high temperature resistance and corrosion resistance, they may still be damaged in certain extreme environments. Therefore, before use, you should fully understand its use environment and conditions to ensure its long-term stable operation.

In summary, silicon carbide ceramic tubes are a high-performance ceramic material pipeline with broad application prospects and huge market potential. During manufacturing and use, relevant standards and specifications should be strictly observed to ensure its quality and safety.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730