Alumina ceramic end effectors, also known as wafer handling end effectors or alumina ceramic manipulators, are an indispensable component of the semiconductor processing and manufacturing industry. The following is a detailed introduction to its characteristics, uses and market conditions:

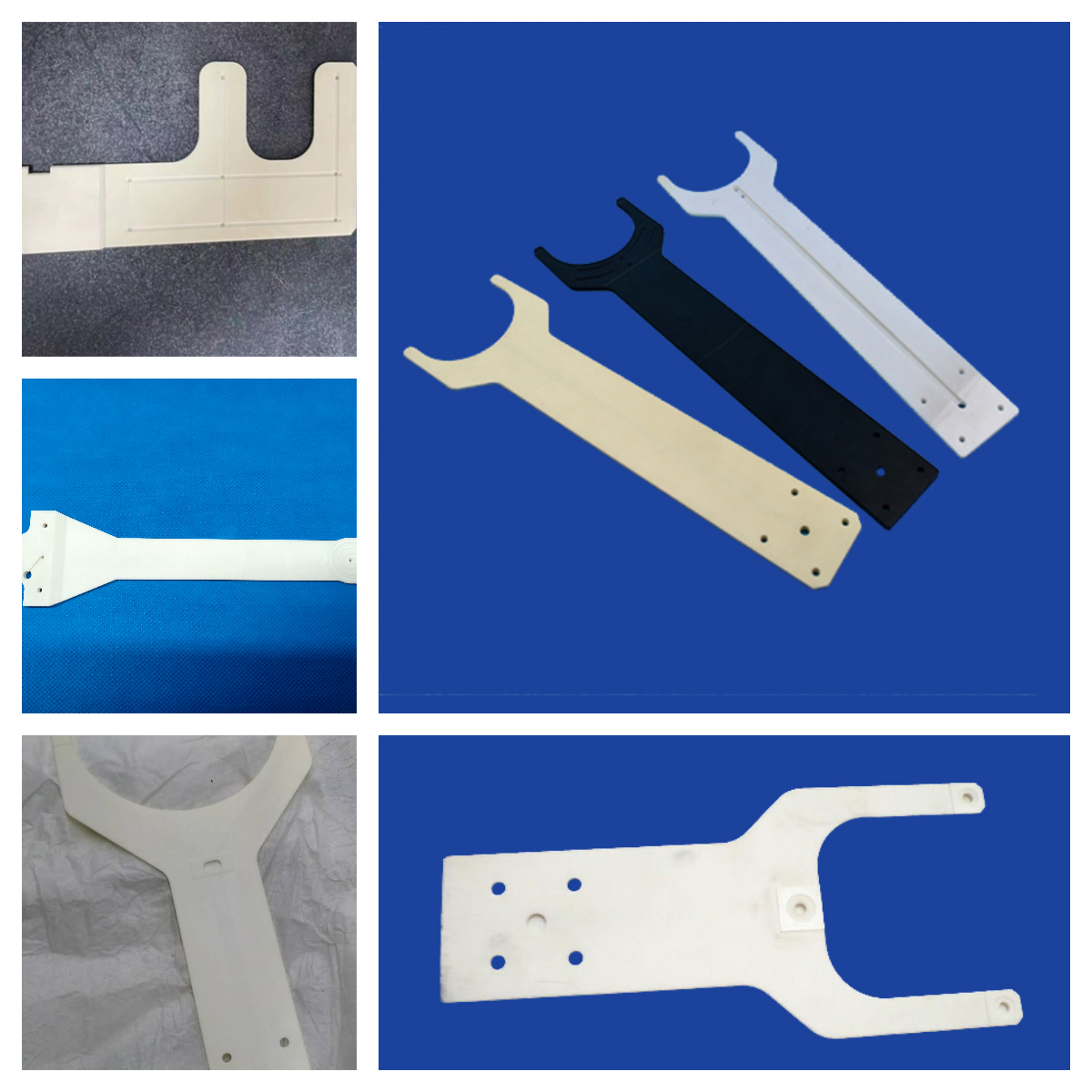

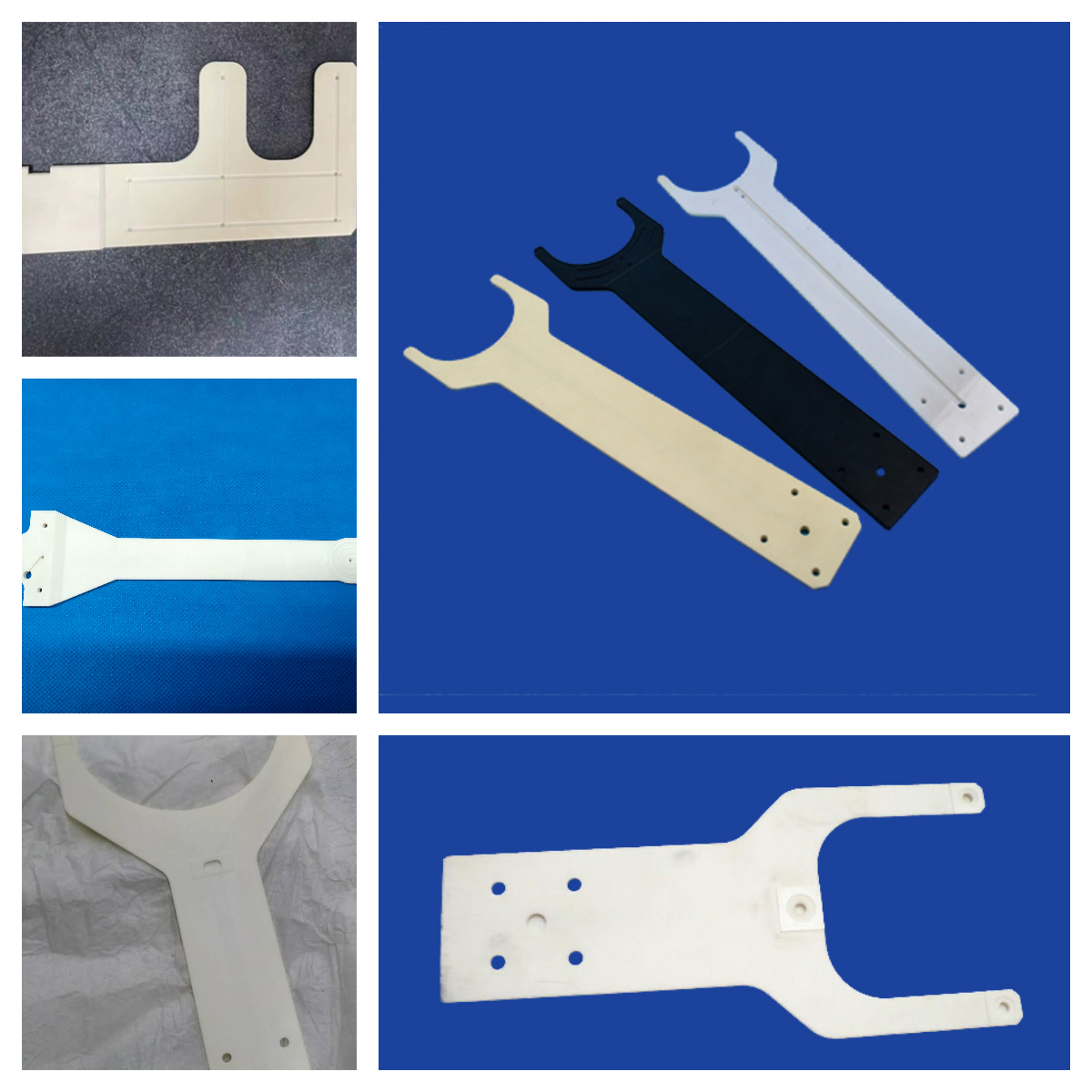

Alumina ceramic end effectors produced by Mingrui Ceramics

1. Characteristics of alumina ceramic end effectors

High temperature resistance: Alumina ceramics have excellent high temperature resistance, with a maximum operating temperature of 1600°C, suitable for high temperature environments in semiconductor manufacturing.

Corrosion resistance: In processes such as cleaning and etching, the alumina ceramic end effector can resist corrosion from various chemical liquids and maintain stability.

Wear resistance: Its wear resistance far exceeds that of steel and chrome steel, and it can maintain stable performance and extend service life during frequent operations.

Anti-static: Suitable for process environments that require isolation of current to ensure the safety of semiconductor devices.

Light weight: It can effectively reduce the load on equipment and increase the service life of equipment.

2. Uses of alumina ceramic end effectors

Alumina ceramic end effectors are mainly used in machines and equipment in semiconductor manufacturing environments, such as EFEM systems, SORTER machines (wafer sorting machines), wafer reversing machines, fully automatic probe test benches, etc. It mainly undertakes the precise positioning and fast and smooth handling of wafers, and can complete the efficient and stable transmission of ultra-thin wafers of various sizes in complex environments. Specific application scenarios include:

Wafer handling: During wafer manufacturing and testing, it is used to grab, carry and place wafers.

Chip pick-up and placement: During chip packaging, chips are picked up from wafers and placed on substrates or packages.

Wire bonding: Used to precisely place and fix wires during the wire bonding process of chip packaging.

Inspection and sorting: Transferring devices from one location to inspection equipment during the inspection and sorting of semiconductor devices.

Etching and deposition equipment: Used to carry and install components in high temperature or corrosive environments during the maintenance and operation of semiconductor equipment.

Cleaning and corrosion process: Operate in a chemical liquid environment without damage during wafer cleaning and corrosion.

3. Market situation of alumina ceramic end effectors

The global ceramic wafer end effector market size is expected to increase from 329 million yuan (RMB) in 2023 to 459 million yuan in 2029, with a compound annual growth rate of 5.73%. Among them, alumina wafer end effectors, as an important component, will also grow in market size. The domestic ceramic wafer end effector market is also showing a steady growth trend, with major companies including ASUZAC Fine Ceramics, CeramTec, JEL Corporation, Kyocera, etc.

4. Types of alumina ceramic end effectors

Alumina ceramic end effectors can be divided into various types such as load-bearing type, vacuum adsorption type, clamping type, Bernoulli type, etc. to meet the needs of different application scenarios.

In summary, alumina ceramic end effectors play an important role in the semiconductor manufacturing industry with their excellent performance and wide application scenarios. With the continuous development of the semiconductor industry, its market demand will continue to grow.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730