Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

Wear resistant ceramic components have best abrasion resistant performace due to the hardness and abrasion resisting of wear ceramic materials is more strength than most metals.

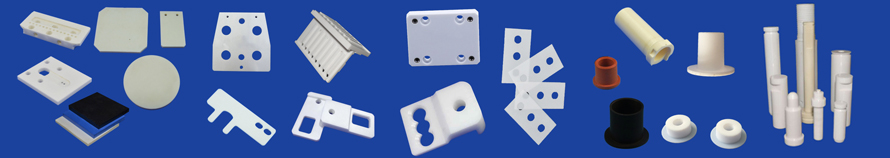

Advanced structural ceramic materials have high hardness and good wear resistance, high temperature resistance, oxidation resistance, excellent abrasion resistance, low expansion coefficient and corrosion resistance, and which wear ceramic component parts have been applied in some industrial fields.such as Silicon Nitride (Si3N4),Silicon Carbide (SiC) Ceramics, Zirconia Ceramics ,Alumina Ceramics,Boron Nitride Ceramics...

The performance of the wear resisting ceramic components and abrasion ceramic parts

1. The hardness

Wear ceramic components rockwell hardness of HRA 80-90, hardness second only to diamond, far more than the wear resistance of wear-resistant steel and stainless steel.

2. Excellent wear resistance

Its wear resistance is 266 times that of manganese steel and 171.5 times that of high chromium cast iron.Under the same working condition, the service life of the abrasion ceramic parts can be extended at least ten times.

3. Light weight

Its density is 3.6-3.9g/cm3, only half of that of steel, wear ceramic component can greatly reduce equipment load.

4. Firm bonding and good heat resistance

Wear-resistant ceramic parts are best glued with high strength ceramic component structure to ensure that the ceramic will not fall off during long-term operation at high temperature.

The some applications of the wear resistant ceramic components

|

1) Wear part Ceramic Nozzles Ceramic Sprayers Cyclones Homogenizing devices Ceramic Linings Milling Systems Ceramic Thread guides |

2) Precision component Ceramic Measuring Components Ceramic Control systems (Micro) dosing valves Electronics Mechatronics Optical applications |

3) Machine & Construction Positioning Guide parts Coatings Transport ceramic rollers Ceramic Dies Textile machine parts Furnace parts |

|

4) Rotating Equipment Ceramic Sliding Bearings Ceramic Ball bearings Mechanical seals Ceramic Plungers Ceramic Valves / fittings Dosing components |

5) Cutting & moulding Ceramic knives Metal-forming tools Seaming rolls Ceramic Punches Drawing dies |

Other industry applications We welcome any customer specific requests. Our engineer will be happy to assist you to define and select the suitable solution for each project. Our official E-mail: admin@cerampart.com |

|

Specification: 1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)... 2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance wear rate 0.68 mm3·m-2·h-1.... 3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm... 4. High Polished Surface Up To Rz0.8(Ra0.1) ... 5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture toughness, 6. Pressure Resistance, Max 2300MPa compressive strength... 7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance... 8. Long Service Life... 9. Other excellent property Ceramic materials for wear ceramic parts: · 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2) |

|

Custom and machining for wear resistant ceramic components

We can produce different sizes and shapes of the wear resistant ceramic component for specific applications to different custom products.Such as drilling, polishing, stripes, concave and convex, screw holes, metal parts position and so on.

|

Processing items: punching, external thread, internal thread, polishing, hollowing out, concave and convex, bending, etc. According to the customer requirement or the drawing.  |

|

||||||||||||||||||||||||||

|

Our Customers

OEM wear ceramic spare components and enjoys on-going relationships with businesses of all sizes in dozens of industries, in addition to the markets showcased at the top of this page, including: |

Contact us CEO : Mr Admin Mobile : +86 18122974730 Tel : +86 0769-85090316-8038 E-mail : admin@cerampart.com Skype: admin@cerampart.com We chat: +86 18122974730 Address:No. 21, Chuangxing Road, Shangsha SecondIndustrial Zone, Chang'an Town, Dongguan City,Guangdong Province,China For more details of the high temperature ceramic component parts , please contact us soon. Our ceramic engineer will be always online. Thanks |

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 | 2200 |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the wear ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

The some tips of the wear resistant ceramic components

Wear is ultimately caused by the material moving away from the worn surface, so the hardness of the ceramic material is no longer a predictive indicator of wear.The brittleness of ceramic materials directly affects the wear rate. With the increase of fracture toughness and hardness of ceramic materials, the wear rate of ceramics gradually decreases and the wear resistance becomes better.The wear rate of ceramics has a linear relationship with fracture toughness. The better the fracture toughness, the better the wear resistance of ceramics.The wear of ceramics is also closely related to the stress state of the surface. The smaller the boundary stress of ceramic fracture is, the more serious the wear of ceramics becomes under the same circumstance.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS