|

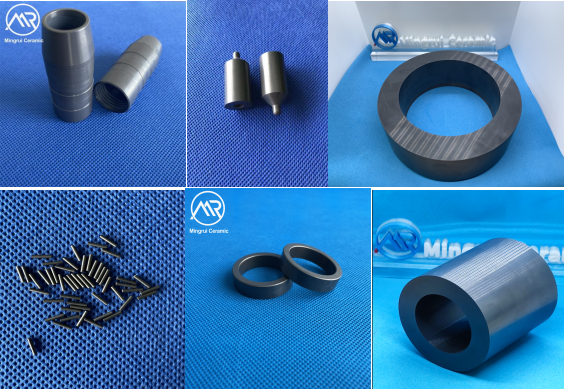

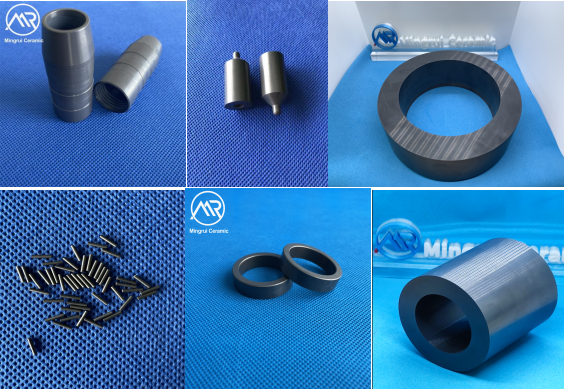

Silicon carbide ceramics (SiC ceramics) are advanced ceramic materials made of silicon carbide as the main component.

The hardness of silicon carbide ceramics is second only to diamonds, making it the second hardest substance in nature. At the same time, its strength is also very high and can withstand greater mechanical stress.

Silicon carbide ceramics have excellent thermal conductivity and can quickly transfer heat away, making them suitable for applications that require efficient heat dissipation.

Silicon carbide ceramics have excellent corrosion resistance to a variety of chemical media and can maintain the integrity of the material in harsh chemical environments.

|

|

| Silicon carbide ceramics have excellent mechanical properties such as high hardness, high strength, high wear resistance, and low friction coefficient. At the same time, it also has good oxidation resistance and corrosion resistance, and can maintain stable performance in high temperature environments. |

|

Properties of Silicon Carbide (SiC) :

Extremely high hardness, Mohs hardness can reach 9.2

Vickers microdensity is 3000-3300kg/mm2

Knoop hardness is 2670-2815kg/mm

Thermal conductivity can reach 120-180W/(m·K), about 4 times that of metal

Thermal expansion coefficient is 4.5×10^-6/K

At room temperature, it is a semiconductor material with a resistivity of more than 10,000Ω·cm

High tensile strength

Low fracture toughness and high brittleness

Excellent high temperature mechanical properties, high temperature strength can be maintained up to 1600℃

Excellent corrosion resistance

Oxidation resistance

Acid and alkali resistance

|

Applications of Silicon Carbide (SiC):

Mechanical industry: high-speed cutting tools, bearings, seals

Energy field: thermal insulation materials, reflectors or high-temperature structures

Aerospace: engine components, thermal protection systems

Chemical and environmental protection: corrosion-resistant pipes, valves, pump bodies

Electronics and semiconductors: integrated circuit substrate materials, packaging materials and heat dissipation materials

Bulletproof equipment: bulletproof equipment and armor materials |

| For more information about ceramics,please contact our engineers in time |

|

|

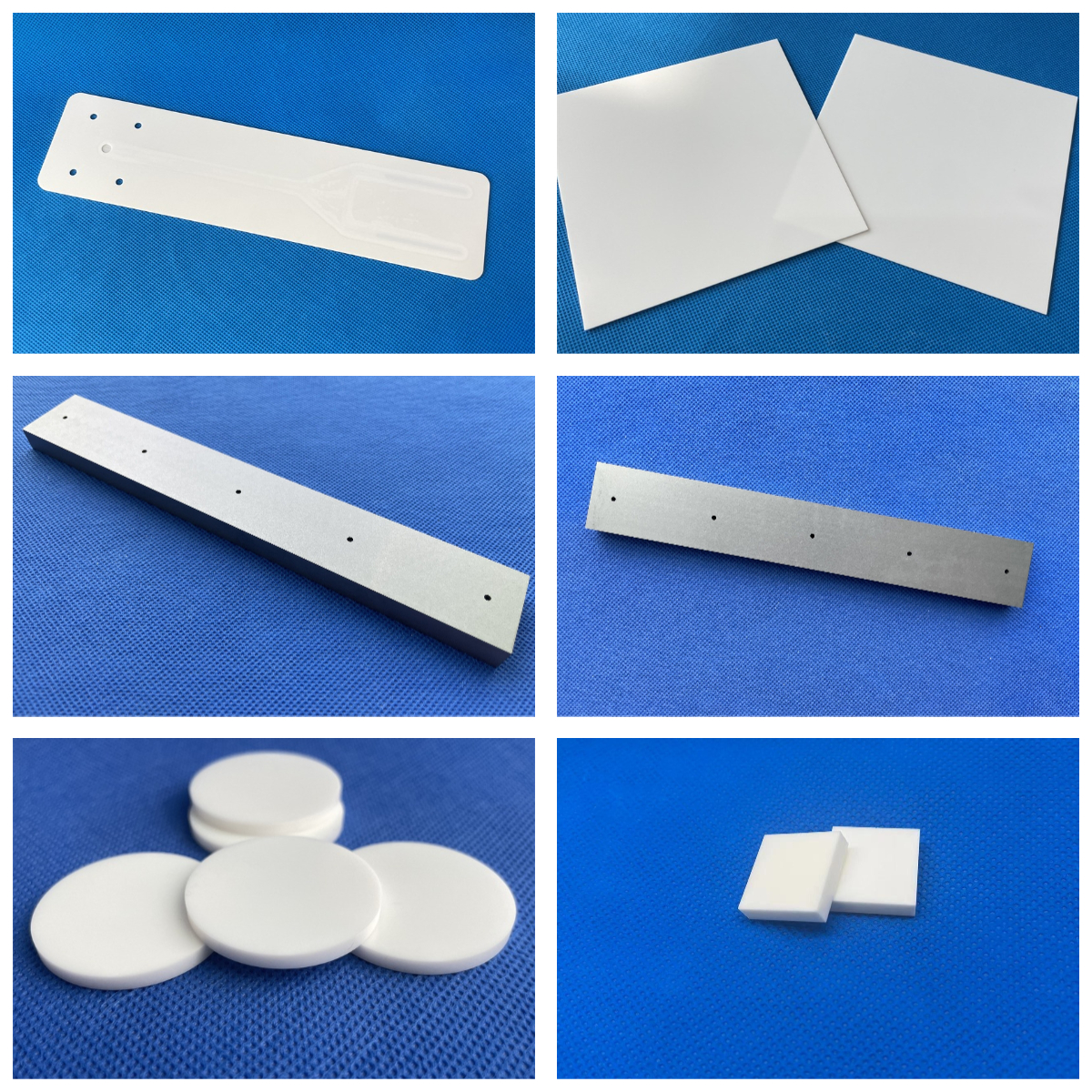

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 |

2200 |

|

Physical Properties:

·Volume ·Density ·Melting point ·Boiling point ·Heat capacity ·Index of reflection ·Porosity (also we refer pore size) |

Mechanical Properties: ·compressive strength ·shear strength ·fracture toughness ·elasticity or plasticity ·ductility ·Hardness |

Electrical Properties: ·dielectric strength ·electrical conductivity ·insulating properties ·semiconducting properties ·superconducting properties ·dielectric constant |

|

Thermal Properties:

·insulating properties ·semi-conducting properties ·thermal conductivity ·thermal expansion ·thermal shock resistance |

Chemical Properties: ·alkali attack resistance ·acid attack resistance ·corrosion resistances |

Other ceramic properties... |

Know more details of the ceramics property, contact us : admin@cerampart.com

|

Customization & Machining Service:

As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by (email:admin@cerampart.com). Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

||||||||||||||||||||||||||

|

The general specifications service

1. Factory price with a discounts 2. Fast shipment within 24 hours 3. In stocks for hot sales sizes 4. MOQ:1qty |

The Custom service 1. Can be custom for special sizes by drawing 2. Can offer a samples within 2 days 3. The delivery time within 20 days after confirmed the order 4. Factory price and Senior ceramic engineer service |

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS