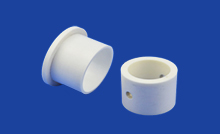

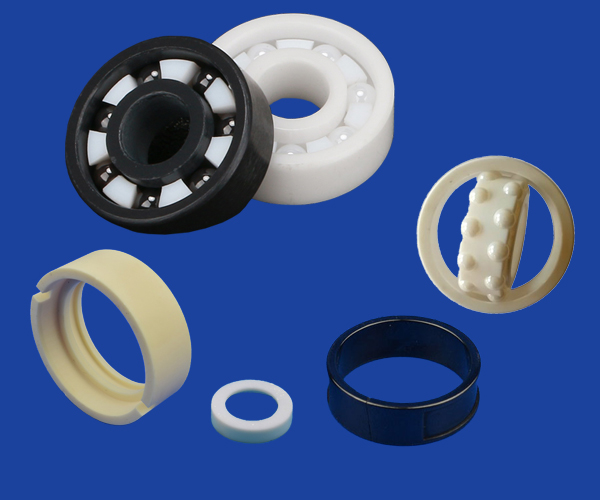

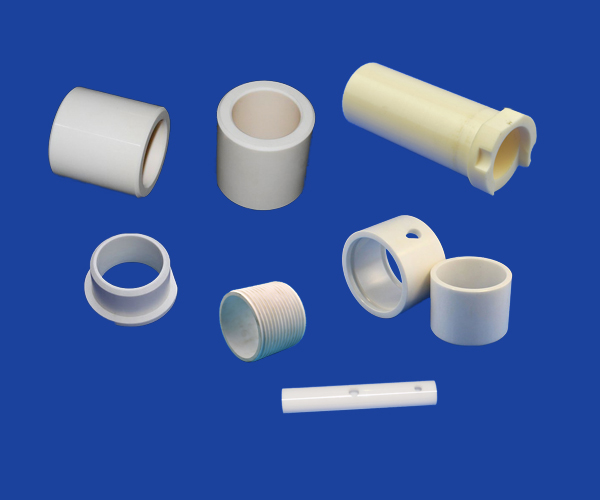

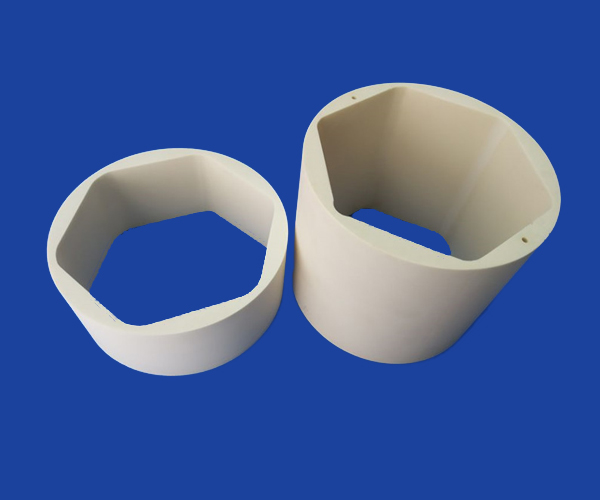

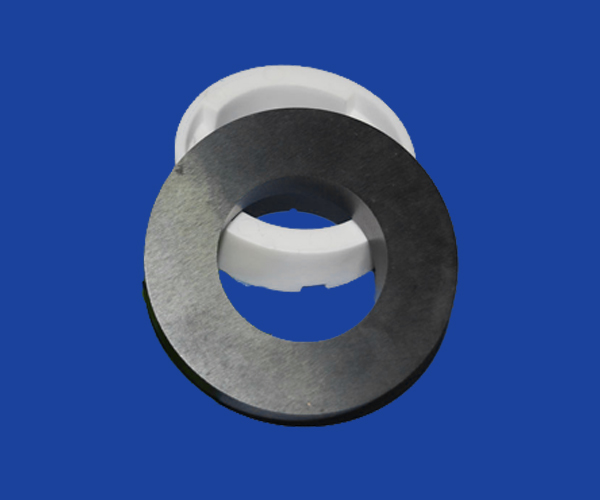

Technical Advance Precision Ceramic Bushing&Sleeves&Liner Series

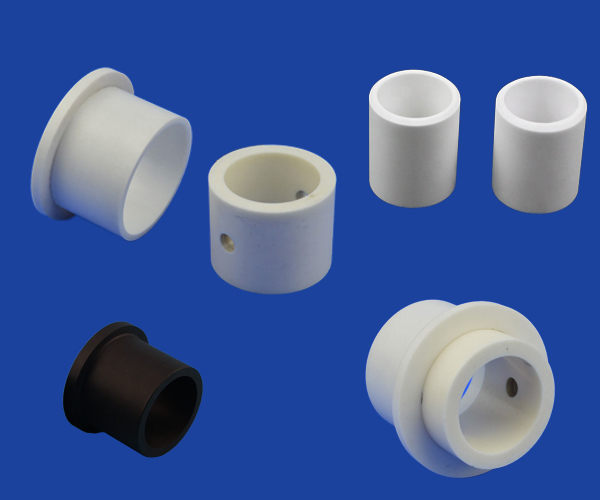

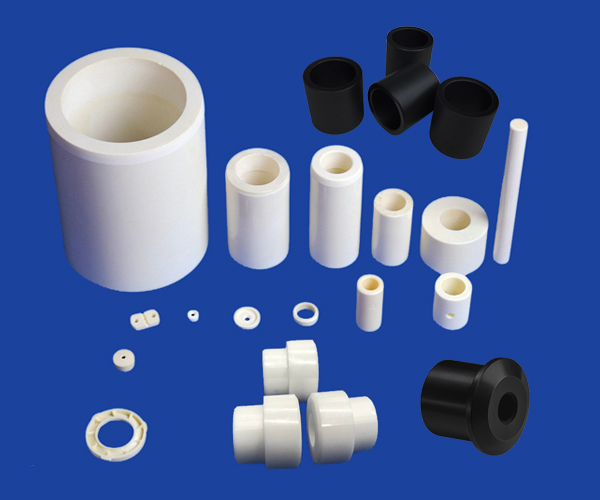

ceramic bushing series |

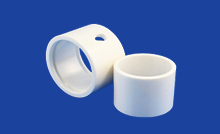

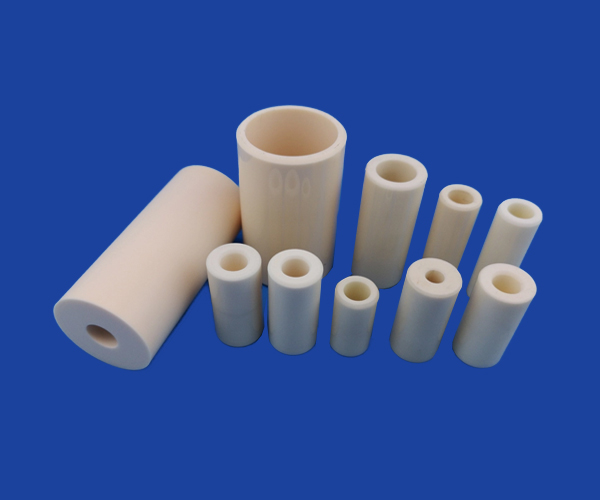

ceramic sleeves series

Shaft Sleeve;Sleeve Bearing...

|

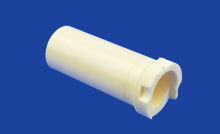

ceramic lining series

Sleeve Liner...

|

ceramic pins series |

Advanced ceramics is more resistant to high temperature,abrasion,low coefficent of friction than metals

Full ceramic sleeve bushing are lighter, smoother, stiffer, harder, corrosion resistant, and electrically resistant. Full Ceramic bearings are used in extreme and in special environments like operating temperature up to + 1750°C. |

Ceramic sleeve bushing has an extremely low coefficient of friction and is ideal for applications seeking to reduce friction. Thermal properties are better than steel balls resulting in less heat generation at high speeds. |

|

Full Ceramic Sleeve Bushing Benefits: · Will not corrode or rust · Resistant to resist acids, alkali, blood, salt and water · Extremely low coefficient of friction and thermal expansion · Lower friction results in less energy consumed · Operating Temperature from as low as (-85°C) up to (+1750°C) |

Ceramic Sleeve Bushing sizes:

·OD Tolerance: +0.027/+0.019 mm ·ID Tolerance: +0.002/+0.008mm ·ID sizes range from 3/16” to 3” ·Can be customized and machinable for special sizes Assembly:Washers;Balls;Shaft; Seal parts; Rod;Bearings... |

|

Do not find similar ceramic bushing products on this page? For more detail of ceramic bushing like price,shipping,samples... Quick Free Quote . Our official E-mail: admin@cerampart.com (Mr admin).thanks |

|

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 |

2200 |

|

Physical Properties:

·Volume ·Density ·Melting point ·Boiling point ·Heat capacity ·Index of reflection ·Porosity (also we refer pore size) |

Mechanical Properties: ·compressive strength ·shear strength ·fracture toughness ·elasticity or plasticity ·ductility ·Hardness |

Electrical Properties: ·dielectric strength ·electrical conductivity ·insulating properties ·semiconducting properties ·superconducting properties ·dielectric constant |

|

Thermal Properties:

·insulating properties ·semi-conducting properties ·thermal conductivity ·thermal expansion ·thermal shock resistance |

Chemical Properties: ·alkali attack resistance ·acid attack resistance ·corrosion resistances |

Other ceramic properties... |

Know more details of the ceramics property, contact us : admin@cerampart.com

|

Customization & Machining Service:

As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by (email:admin@cerampart.com). Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

||||||||||||||||||||||||||

|

The general specifications service

1. Factory price with a discounts 2. Fast shipment within 24 hours 3. In stocks for hot sales sizes 4. MOQ:1qty |

The Custom service 1. Can be custom for special sizes by drawing 2. Can offer a samples within 2 days 3. The delivery time within 20 days after confirmed the order 4. Factory price and Senior ceramic engineer service |

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS