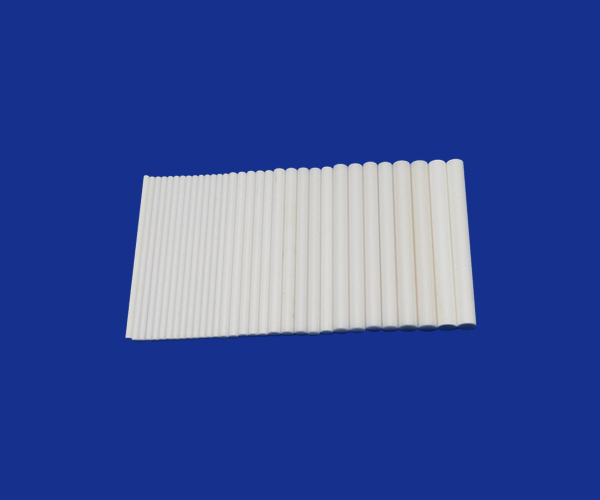

Pin Type

|

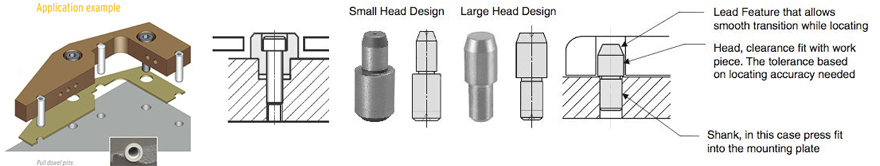

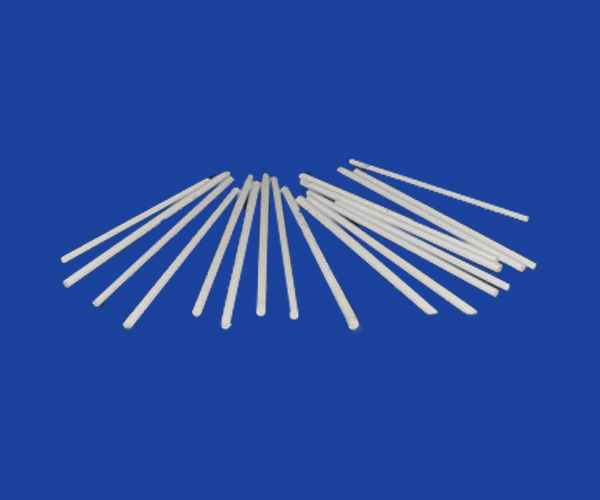

Straight Dowel

|

Straight dowel pins are cylindrical pins that join two pieces together to prevent motion or slippage.

|

|

Oversize Dowel

|

Oversized dowel pins are manufactured slightly over the nominal size.

|

|

Undersize Dowel

|

Undersized dowel pins are manufactured slightly under the nominal size.

|

|

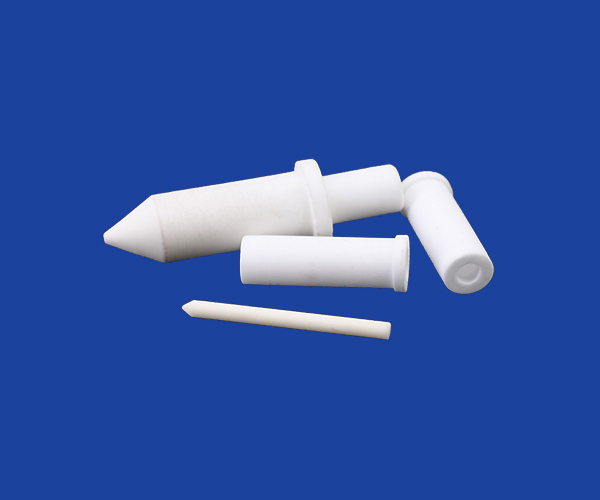

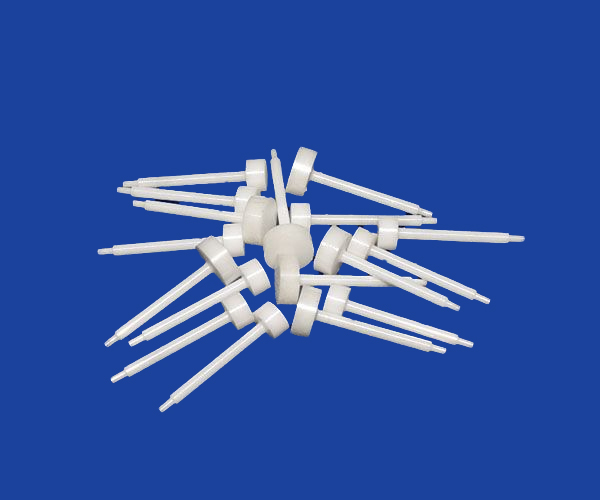

Pull Dowel Pin

|

Pull dowel pins have a threaded hole in one end so that a screw can be inserted to help remove the pin from a blind hole.

|

|

Groove Pin

|

Grooved pins are cylindrical pins with longitudinal grooves. They are used to join two components. Grooves provide greater surface area for adhesive, and offer improved holding power.

|

|

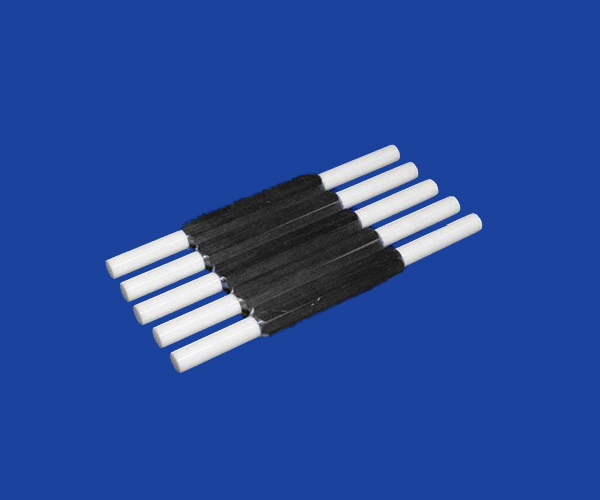

Knurled Pin

|

Knurled pins are straight pins with a knurled surface. a better grip than a smooth dowel pin.

|

|

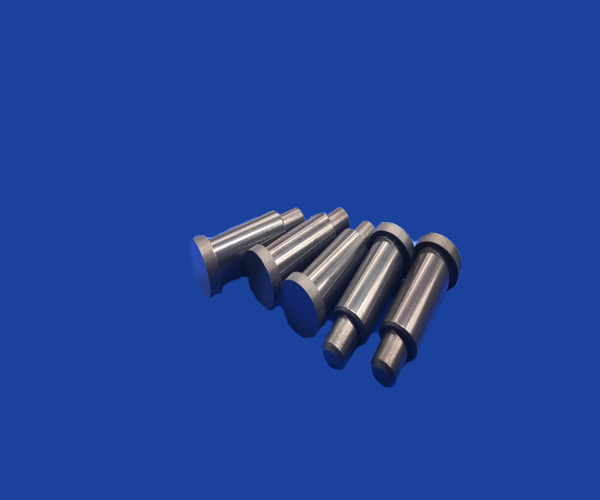

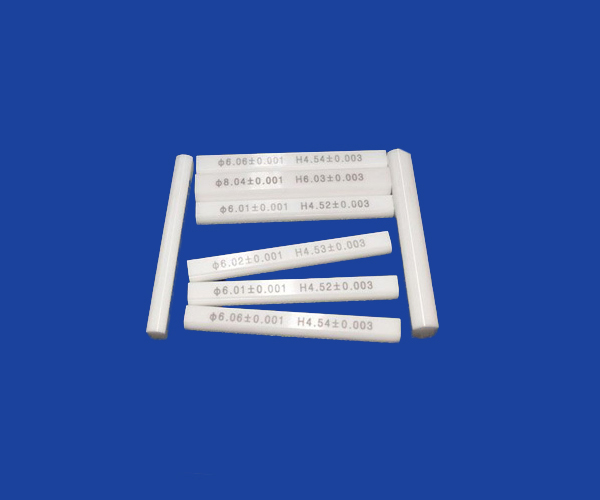

Parallel Pin

|

Parallel pins are cylindrical dowel pins that have the ends machined to two different tolerances.

|

|

Other pin types

|

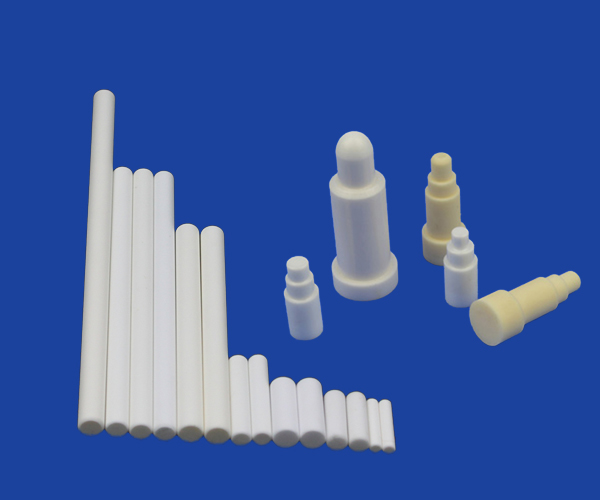

Welding pin, centring pin, dowel pin, position pin,needle pin, locating pin etc |

|

Do not find similar ceramic pin products on this page? For more detail of ceramic pin like price,shipping,samples... Quick Free Quote . Our official E-mail: admin@cerampart.com (Mr admin).thanks |

|

|

|

Al 2O 3 |

ZrO2/Y2O3 | ZrO2/MgO | MgO | SiC | Si3N4 Reaction sintered | Si3N4 Hot pressed | ALN |

| Physical properties | ||||||||

| Density (g/cm3) | 3,9 | 5,9 | 5,75 | 3,58 | 3,2 | 3,27 | 3,29 | 3,26 |

| Molecular weight (g/mole) | 102 | - | - | 40,4 | 40,1 | 140 | 140 | 41 |

| Maximum service temperature air (°C) | 1700- 1800 | 1500 | 1000 | 2200 | 1500 | 1200- 1500 | 1100- 1600 | 1000- 1800 |

| Mechanical properties | ||||||||

| Hardness (Mohs) | 9 | - | - | 5,5 | 9 | - | - | 7 |

| Modulus of elasticity (GPa) | 300-400 | 200 | 200 | 250-300 | 420 | 170-220 | 280-310 | 318 |

| Poisson's ratio | 0,25 | - | - | 0,18 | 0,14 | 0,25-0,26 | 0,27 | 0,25 |

| Fracture toughness (MPa.m1/2) | 2-3 | 7-13 | 6-10 | - | 2,5-3,5 | 3,5-5 | 6,1 | 4,5 |

| Electrical properties | ||||||||

| Dielectric constant | 9-10 | - | - | 9-10 | - | 10 | 10 | 9,2 |

| Electrical resistivity at 20°C (Ohm.cm) | >10 14 | 10 13-10 14 | >10 10 | - | 10 2-10 6 | >10 7 | 10 12- 10 15 | >10 14 |

| Dielectric strength (kV/mm) | 10-20 | 9 | 2-10 | - | - | - | - | 15 |

| Thermal properties | ||||||||

| Specific heat (J/K/kg) | 900 | 400-500 | 420 | 870-880 | 750 | 690 | 680-800 | 800 |

| Thermal conductivity (W/m/K) at 20°C | 26-35 | 2,2-3,2 | 1,5-2,5 | 40-50 | 63-155 | 9-30 | 15-43 | 180 |

| Coefficient of thermal expansion ( 10-6) from 20 to 1000°C | 8-9 | 10-11 | 5-16 | 10-13 | 4-5 | 3 | 3,3 | 4,4-5,3 |

| Melting point (°C) | 2050 | 2590 | - | 2800 | 2500 | 1900 | 1900 |

2200 |

|

Physical Properties:

·Volume ·Density ·Melting point ·Boiling point ·Heat capacity ·Index of reflection ·Porosity (also we refer pore size) |

Mechanical Properties: ·compressive strength ·shear strength ·fracture toughness ·elasticity or plasticity ·ductility ·Hardness |

Electrical Properties: ·dielectric strength ·electrical conductivity ·insulating properties ·semiconducting properties ·superconducting properties ·dielectric constant |

|

Thermal Properties:

·insulating properties ·semi-conducting properties ·thermal conductivity ·thermal expansion ·thermal shock resistance |

Chemical Properties: ·alkali attack resistance ·acid attack resistance ·corrosion resistances |

Other ceramic properties... |

Know more details of the ceramics property, contact us : admin@cerampart.com

|

Customization & Machining Service:

As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by (email:admin@cerampart.com). Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

||||||||||||||||||||||||||

|

The general specifications service

1. Factory price with a discounts 2. Fast shipment within 24 hours 3. In stocks for hot sales sizes 4. MOQ:1qty |

The Custom service 1. Can be custom for special sizes by drawing 2. Can offer a samples within 2 days 3. The delivery time within 20 days after confirmed the order 4. Factory price and Senior ceramic engineer service |

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS