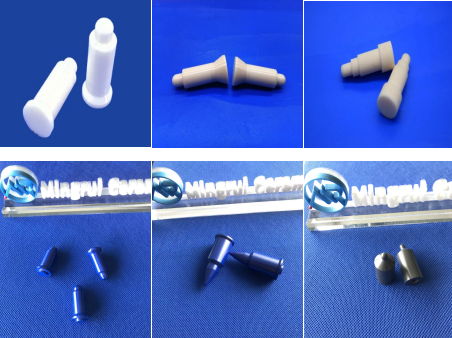

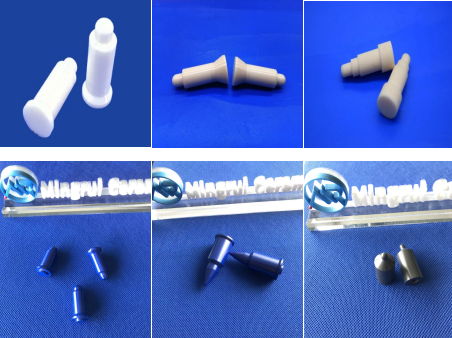

Zirconia Zro2 ceramic positioning pin M4 M5 M6 M8 M10 M12 Locating Ceramic Pin Ceramic Guide Pins For Nut Spot Welding

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Mini-OD: 0.02mm;Max-length: 500mm

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:High hardness, high strength, low density, high temperature resistance, wear resistance and corrosion resistance

- Customized:Can be custom for special sizes and shapes

1. Factory price and shipment within 24 hours In stocks

2. MOQ:1qty

3. Payment Term: PayPal; T/T; L/C etc.

4. Shipment: by sea by air by courier by post etc.

Zirconia Zro2 ceramic positioning pin M4 M5 M6 M8 M10 M12 Locating Ceramic Pin Ceramic Guide Pins For Nut Spot Welding

Ceramic pin is a cylindrical pin mainly made of zirconia ceramic material. It has the characteristics of high hardness, high strength, low density, high temperature resistance, wear resistance and corrosion resistance. It is suitable for various application scenarios with high performance requirements.

Ceramic pins produced by Mingrui Ceramics.

Compared with traditional metal pins, ceramic pins have higher hardness and strength, can withstand higher loads and stresses, and have a longer service life. In addition, ceramic pins have better high temperature resistance and corrosion resistance, and can work in harsh environmental conditions.

Zirconia ceramic pins have high wear resistance and high corrosion resistance, and can maintain excellent performance in high temperature environments. In addition, zirconia ceramic pins also have high hardness and strength, can withstand high loads and stresses, and are suitable for various occasions that require high-strength fastening. Therefore it has a wide range of applications in many fields.

The following are the advantages, properties and applications of zirconia ceramic pins:

1. Advantages:

-

High hardness: The hardness of the zirconia ceramic pin is close to Mohs hardness 9.5, which is higher than most metal materials and traditional ceramic materials, which makes it have good performance in wear resistance, scratch resistance, etc.

-

High strength: Zirconia ceramics have high flexural strength and compressive strength. Its strength is close to that of steel and can even exceed that of some metal materials. Therefore, it exhibits good stability under high loads and stresses.

-

Good corrosion resistance: It can resist the erosion of chemical media such as acids and alkalis, and shows excellent performance in medical equipment, chemical industry and other fields.

2. Features:

-

Zirconia ceramic pins have high wear resistance and low friction coefficient, and can effectively maintain stable performance during long-term use.

-

It has excellent biocompatibility and will not cause allergic or rejection reactions when in contact with human tissue. Therefore, it is widely used in medical fields such as dentistry and orthopedics.

-

Excellent insulation properties and dimensional stability make it an ideal choice for manufacturing electronic devices, insulating substrates and electronic packaging materials.

3. Application:

-

In the automotive field, it is used to manufacture engine parts, sensors, seals, etc. to improve the performance and efficiency of the car.

-

In the electronics field, it is used to manufacture electronic components such as capacitors, resistors, transformers, etc.

-

In the energy field, it is used to manufacture high-temperature stoves, solar panels and other equipment in high-temperature environments.

-

In the aerospace field, it is used to manufacture high-temperature insulators, radomes and other key components on aerospace vehicles.

-

In the medical field, it is used to manufacture medical devices, precision instruments and other occasions that require high-strength fastening.

In short, zirconia ceramic pin is a high-performance fastener with wide application prospects. With the continuous advancement of science and technology and the growing demand for applications, its application fields will also continue to expand.

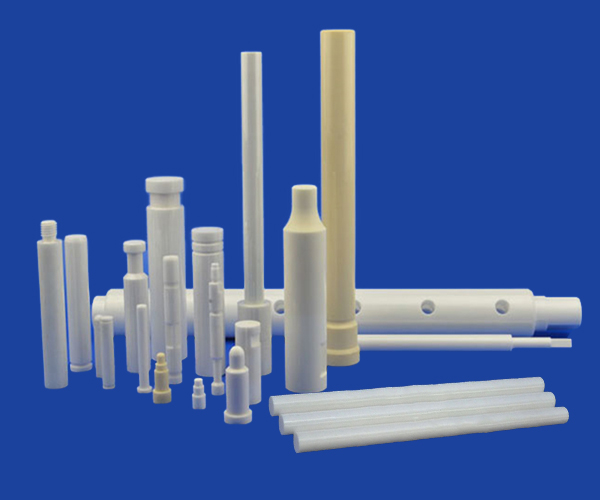

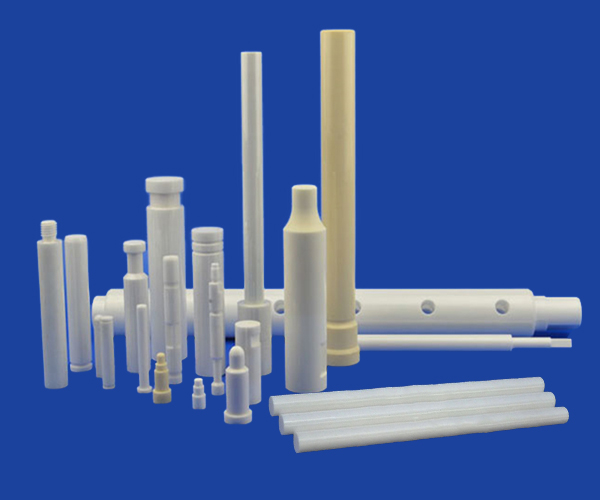

we can produce ceramic pin of different sizes, not limited to the following table.

The sizes of some ceramic pin are as follows :

Outer Diameter

(Inch) |

Outer Diameter

(mm) |

Length

(mm)(in) |

|

0.011 |

0.28 |

10 |

0.39 |

|

0.02 |

0.51 |

19 |

0.75 |

|

0.022 |

0.56 |

150 |

5.91 |

|

0.024 |

0.61 |

210 |

8.27 |

|

0.096 |

2.44 |

230 |

9.06 |

|

0.011 |

0.28 |

80 |

3.15 |

|

0.02 |

0.51 |

20 |

0.79 |

|

0.022 |

0.56 |

34 |

1.34 |

|

0.024 |

0.61 |

53 |

2.09 |

|

0.096 |

2.44 |

75 |

2.95 |

|

0.125 |

3.18 |

90 |

3.54 |

|

0.137 |

3.48 |

130 |

5.12 |

|

0.083 |

2.1 |

110 |

4.33 |

|

0.047 |

1.2 |

95 |

3.74 |

|

0.126 |

3.2 |

84 |

3.31 |

|

0.157 |

4 |

340 |

13.39 |

|

0.236 |

6 |

210 |

8.27 |

|

0.188 |

4.78 |

110 |

4.33 |

|

0.197 |

5 |

95 |

3.74 |

|

0.212 |

5.38 |

84 |

3.31 |

|

0.25 |

6.35 |

340 |

13.39 |

|

0.264 |

6.71 |

210 |

8.27 |

|

0.327 |

8.3 |

110 |

4.33 |

|

0.339 |

8.6 |

95 |

3.74 |

|

0.354 |

9 |

84 |

3.31 |

|

0.433 |

11 |

340 |

13.39 |

|

0.551 |

14 |

210 |

8.27 |

|

0.64 |

16.26 |

180 |

7.09 |

|

0.75 |

19.05 |

360 |

14.17 |

|

0.775 |

19.69 |

440 |

17.32 |

|

1.1 |

27.94 |

520 |

20.47 |

|

1.35 |

34.29 |

340 |

13.39 |

|

Dimension and Tolerance:

· Diameter as small as 0.2mm, depends on length

· Diameter tolerance we could make as fine as 0.001mm

As for the price, please provide the detailed requirements of the ceramic rod to us, such as: size, region, quantity, whether to customize and so on.If you provide detailed information, we will check all the costs and the delivery time is faster.

Custom service:

We are a professional manufacturer of ceramic rods, selling hot sizes of ceramic rods in stock, also support to customize different specifications of ceramic rods, according to the parameters or drawings provided by the customer.

Quick Free Quote . Our official E mail: admin@cerampart.com (Mr admin)

Dimension and Tolerance:

· Diameter as small as 0.2mm, depends on length

· Diameter tolerance we could make as fine as 0.001mm

As for the price, please provide the detailed requirements of the ceramic rod to us, such as: size, region, quantity, whether to customize and so on.If you provide detailed information, we will check all the costs and the delivery time is faster.

Custom service:

We are a professional manufacturer of ceramic rods, selling hot sizes of ceramic rods in stock, also support to customize different specifications of ceramic rods, according to the parameters or drawings provided by the customer.

Quick Free Quote . Our official E mail: admin@cerampart.com (Mr admin)

|

Type of ceramic rods us manufacturer (including but not only belows)

|

Shaft plunger |

Center rod |

Other materials:

· 95%--99.99% Alumina (Al2O3)

· Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2) |

|

Wear rod bar stick |

Pump plunger rod |

|

Pins rod |

Positioning bar |

|

Piston rod |

Plunger rod |

|

Rail bar |

Sleeve and bushing plunger |

|

Machinable rods |

Other type rods |

Tip:

For different industries, equipment,and environment, ceramic pins have different function,We can manufacturing ceramic rod by drawing, such as surface polishing, internal and external pipe wall threads, metal parts bonded, different shapes etc by custom requirement. |

The general specifications service

1. Factory price with a discounts

2. Fast shipment within 24 hours

3. In stocks for hot sales sizes

4. MOQ:1qty

5. Online service  |

The Custom service

1. Can be custom for special sizes by drawing

2. Can offer a samples within 2 days

3. The delivery time within 20 days after confirmed the order

4. Factory price and Senior ceramic engineer service

5. Online service  |

The properties of ceramics

|

· Flexural strength |

· Chemical resistance |

· Electrical insulation |

· Corrosion resistance |

· Dielectric strength |

|

· Wear resistance |

· Temperature resistance |

· Thermal conductivity |

· High voltage |

· Hardness... |

Ceramic materials(include but not limited belows)

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride · TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2) · ZDY: Yttria fully stabilized Zirconia (ZrO2)...

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730