Overview

Features

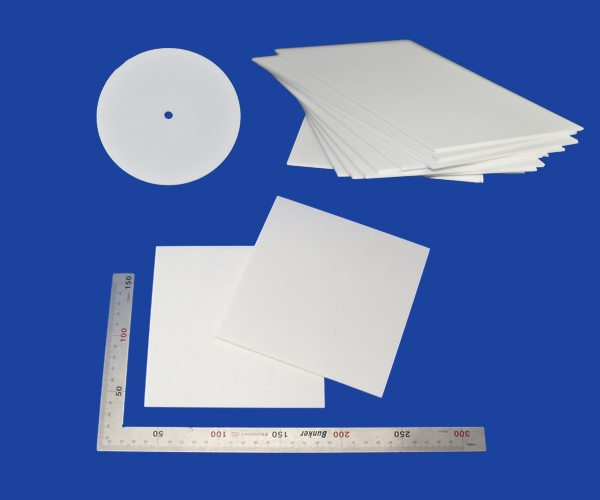

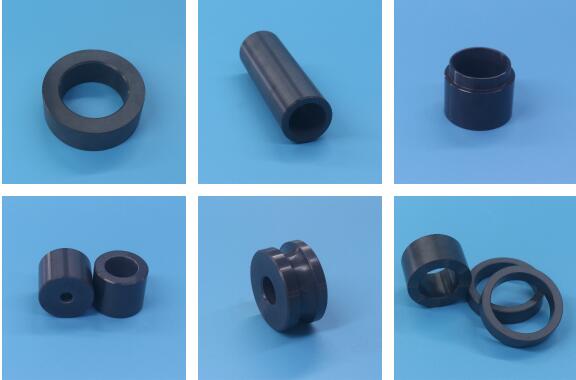

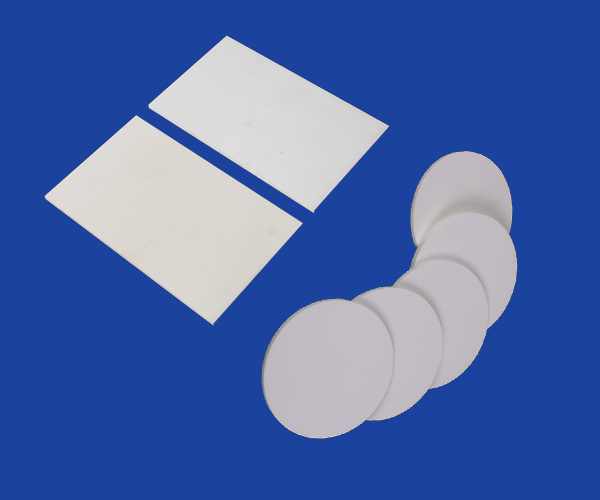

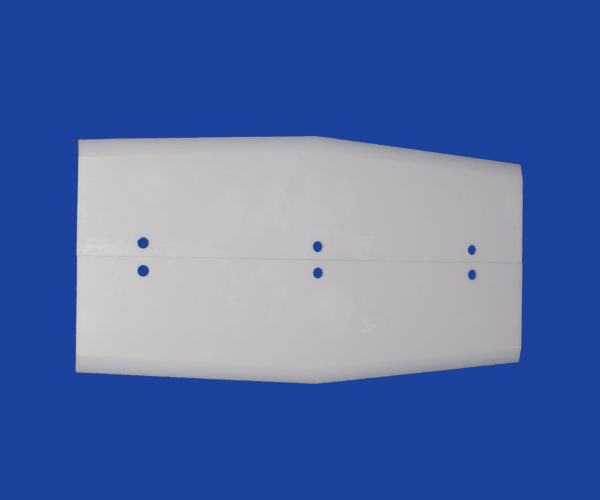

Materials

Application

Machining

1. Zirconia ceramics wear resistance, high hardness, low noise, impact resistance, easy to provide constant service quality, long service life.

2. Zirconia ceramics can increase the space around the wire, increase torque, increase speed, increase blade space, and improve fan efficiency.

3. Zirconia ceramic high-temperature resistance, ≤1000℃, no deformation, no distortion, no lubrication at high speed.

4. Zirconia ceramics are more suitable for working in harsh environments.Such as acid, alkaline environment, oxidation environment, etc.

5. Zirconia ceramics have low density, non-magnetic properties and strong insulation.

6. Zirconia ceramics with low heat conduction, low CTE, wear resistance only second with diamond.

| Item | Unit | zirconia |

| Density | g/cm3 | 6.05 |

| Water absorption | % | 0 |

| Coefficient of thermal expansion | 10-6 /k | 10.5 |

| Young's elastic modulus | Gpa | 210 |

| Poisson-Pine ratio | / | 0.3 |

| Hardness (HV) | MPa | 1200 |

| Bending strength (room temperature) | MPa | 950 |

| Bending Strength (700 ℃) | MPa | 210 |

| Compressive strength (room temperature) | MPa | 2000 |

| Fracture toughness | Mpa.m1/2 | 10 |

| Thermal conductivity (room temperature) | W/m.k | 2 |

| Specific resistivity (room temperature) | Ω.mm2/m | >1015 |

| Corrosion resistance of acid and alkali resistance | / | strength |

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

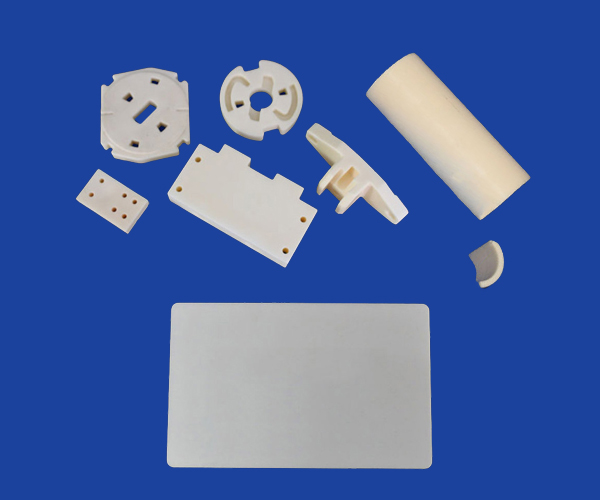

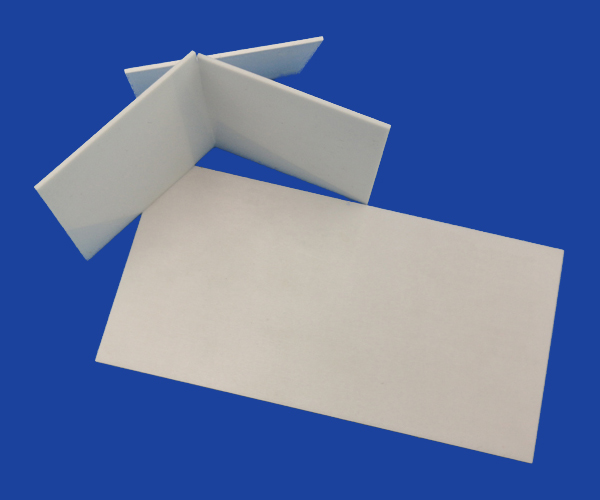

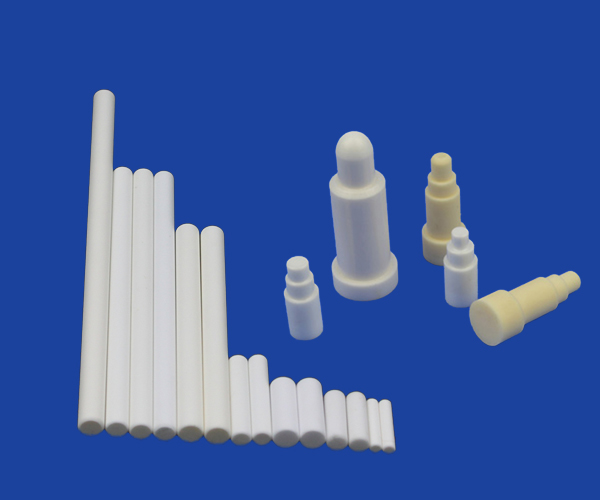

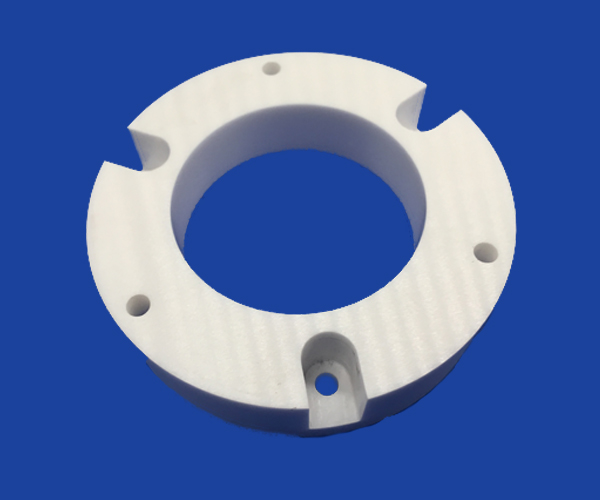

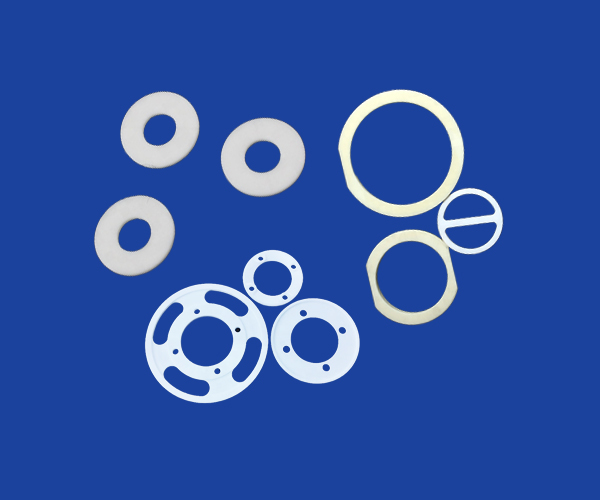

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS