Engineering technical ceramics, also known as engineered technical ceramics or high-temperature structural ceramics, are a new type of ceramic material with excellent performance. The following is a detailed description of engineering technical ceramics' introduction, advantages and applications:

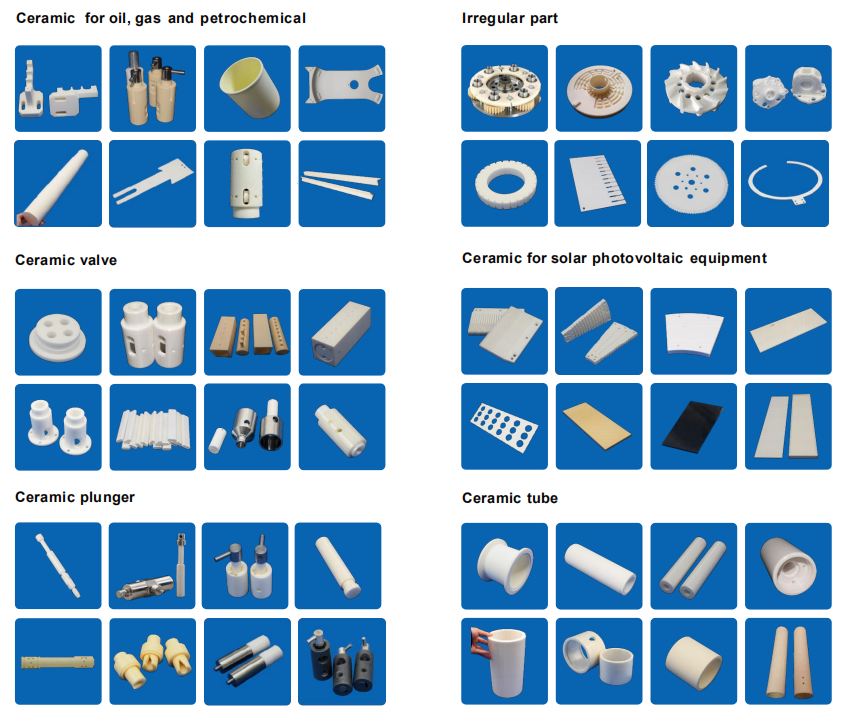

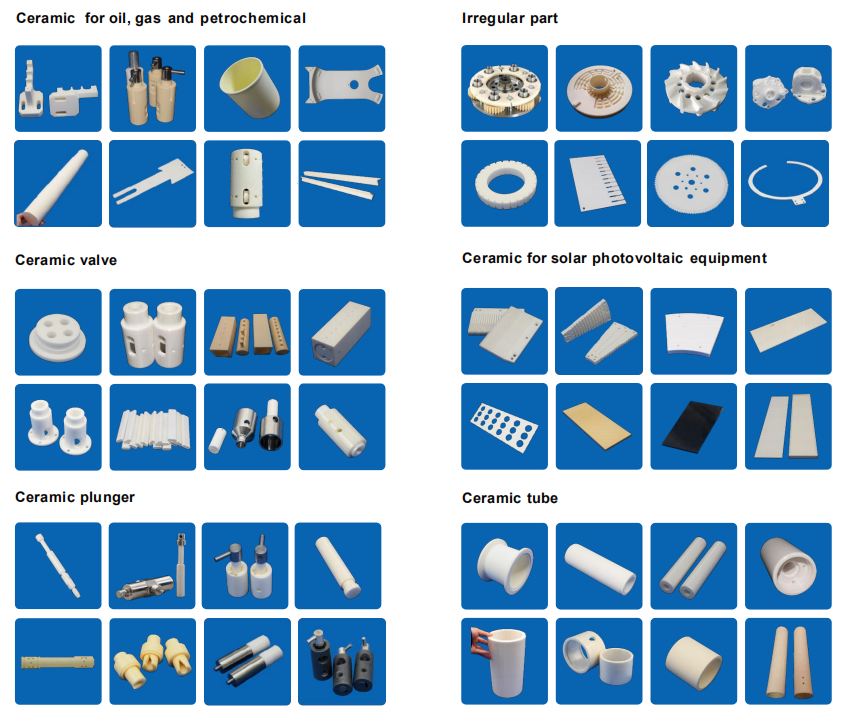

Engineering technical ceramics produced by Mingrui Ceramics.

1. Introduction to engineering technical ceramics

Engineering technical ceramics are inorganic non-metallic materials made of artificially synthesized high-purity inorganic compounds as the main raw materials, through sintering, molding and other special treatments. It has many superior properties that traditional ceramics do not have, such as high temperature resistance, corrosion resistance, high hardness, wear resistance, oxidation resistance, ablation resistance, etc. These characteristics make engineering technical ceramics have broad application prospects in many fields.

2. Advantages of engineering technical ceramics

High temperature resistance: Engineering technical ceramics can maintain stable performance in high temperature environments, and some ceramic materials can even withstand high temperatures close to or exceeding 2000 degrees.

Corrosion resistance: Due to the use of high-purity inorganic compounds as raw materials, engineering technical ceramics have extremely strong corrosion resistance and can resist the erosion of various acids, alkalis, salts and other chemical substances.

High hardness and wear resistance: The hardness of engineered technical ceramics is usually much higher than that of traditional metal materials, and they have excellent wear resistance and can maintain a long service life in high friction and high wear environments.

Antioxidation: At high temperatures, engineered technical ceramics can maintain stable chemical properties and are not easy to react with oxygen, thus avoiding performance degradation caused by oxidation.

Good electrical insulation: Some engineered technical ceramics also have excellent electrical insulation properties and are suitable for occasions with high electrical insulation requirements.

3. Application of engineered technical ceramics

Aerospace field: engineered technical ceramics are widely used in the aerospace field, such as manufacturing engine parts, thermal barrier coatings, brakes, etc. These parts need to withstand extreme conditions such as high temperature, high pressure, and high speed, and engineered technical ceramics are the ideal materials to meet these requirements.

Chemical field: In the chemical industry, engineered technical ceramics are used to manufacture wear-resistant coatings, anti-corrosion equipment, and chemical storage tanks with stable chemical properties such as acid, alkali, and salt resistance. Its excellent corrosion resistance and wear resistance enable these equipment to maintain long-term stable operation in harsh chemical environments.

Electronics: The application of engineered technical ceramics in the electronics field is also very important, such as the manufacture of capacitors, resistors, electronic device housings, etc. These components need to have good insulation and stability to ensure the normal operation of electronic equipment.

Mechanical field: In the mechanical industry, engineered technical ceramics are used to manufacture key components such as bearings, gears, piston rings, etc. These components need to withstand extreme conditions such as high loads and high speeds, and the high hardness and wear resistance of engineered technical ceramics make them an ideal choice.

Medical field: The application of engineered technical ceramics in the medical field is also gradually increasing, such as the manufacture of hard artificial joints, dental restoration materials, etc. These materials have good biocompatibility and stability, and can meet the high requirements of material performance in the medical field.

In summary, engineered technical ceramics play an important role in many fields with their excellent performance and broad application prospects. With the continuous advancement of science and technology and the continuous improvement of people's requirements for material performance, the application field of engineered technical ceramics will continue to expand and deepen.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730