Mingrui Ceramics has added silicon carbide as one of its main self-made materials. It is currently building a silicon carbide ceramic production line and will soon put it into formal production. This can better ensure the quality and stability of the material. In the past, All ceramic bodies of silicon carbide ceramic parts are purchased from outside and then processed. To a certain extent, the purity and stability of the silicon carbide ceramic body cannot be guaranteed. Currently, the silicon carbide sintering process used by Mingrui is reaction sintering.

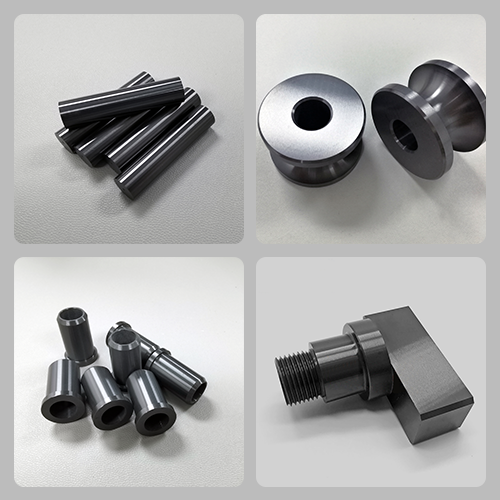

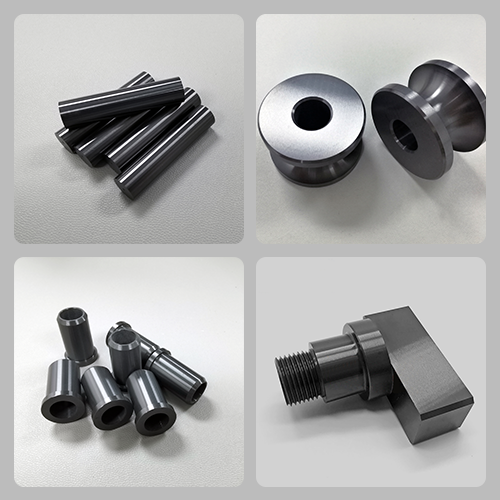

silicon carbide ceramic parts

1. Overview of pressureless sintered silicon carbide

Pressureless sintered silicon carbide refers to adding some sintering aids and binders to silicon carbide powder with similar properties at room temperature to form a shape structure, and then sintering it at high temperature. Finally, the product has higher density, wear resistance, and Silicon carbide products with good high temperature stability. Pressureless sintered silicon carbide products have excellent fire resistance, high temperature resistance, oxidation resistance, corrosion resistance and mechanical properties, and are widely used in electric power, machinery, chemical industry, aviation, national defense and other fields.

(1) Raw material selection

The prerequisite for the preparation of pressureless sintered silicon carbide is silicon carbide powder with high purity and uniform particle size. These silicon carbide powders are usually produced by fine pulverizing technology. During the pulverizing process, processing parameters need to be precisely controlled to achieve uniform particle size and high purity.

The role of the sintering aid is to increase the interaction force between the powders during sintering and promote the combination of particles at high temperature. Commonly used sintering aids include boric acid and boron nitride, which can also react under zero pressure and form high-temperature and stable boron oxide phases and boron nitride phases, thereby increasing the compaction and sintering performance of silicon carbide powder.

(2) Hybrid molding

In the hybrid molding process, a certain amount of binder needs to be added to bond the silicon carbide powder into a workpiece of a certain shape.

Commonly used binders are water glass, polymer, etc. While adding the binder, it is necessary to pay attention to the type and degree of adhesion of the binder to ensure uniform and strong bonding during sintering.

(3) Sintering

During the sintering process, it needs to be heated to a high temperature to form chemical bonds and interaction forces between the powder particles to form a dense sintered body. The selection of sintering temperature and time is the key to preparing pressureless sintered silicon carbide products, and they need to be adjusted according to the specific conditions and usage requirements of the sample.

Reaction sintered silicon carbide is a product obtained by reacting silicon carbide and carbon at high temperature. Unlike pressureless sintered silicon carbide, reaction sintered silicon carbide does not require the addition of additional sintering aids and binders, so the quality of the sintered products is more stable and stronger.

2. Preparation process of reaction-sintered silicon carbide

The raw materials of reaction sintered silicon carbide include carbon and silicon carbide. Silicon carbide is usually of high purity, and the addition amount and particle size should be kept within a certain range. After carbon and silicon carbide are mixed, they need to be uniformly mixed by mechanical means.

(1) Thermoforming

The hot press forming of reaction sintered silicon carbide includes two stages of cold pressing and hot pressing. During the cold pressing stage, pressure is required to initially combine the carbon and silicon carbide particles. In the hot pressing stage, it needs to be heated to high temperature to completely react the carbon and silicon carbide particles to form silicon carbide, which is then compressed into one body at high temperature.

(2) heat treatment

During the heat treatment process, the quality and structure of the product need to be further adjusted through cooling, passivation, atmosphere control, etc.

Although pressureless sintered silicon carbide and reaction sintered silicon carbide are both high-quality silicon carbide products, they have some significant differences.

(1) Preparation process: Pressureless sintered silicon carbide requires the addition of sintering aids and binders, while reaction sintered silicon carbide does not require the addition of additional substances and is simpler to operate.

(2) Cost: Since pressureless sintered silicon carbide requires the addition of sintering aids and binders, the preparation cost is higher.

(3) Quality: The quality of reaction-sintered silicon carbide products is more stable and solid. Since it does not contain other substances, there will be no impurities such as sintering aids and binders.

(4) Performance: Although both products have excellent high temperature resistance, corrosion resistance and mechanical properties, reaction-sintered silicon carbide is more resistant to high temperature and corrosion.

In summary, which preparation method to choose depends on factors such as the specific use of the product, requirements and budget.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730