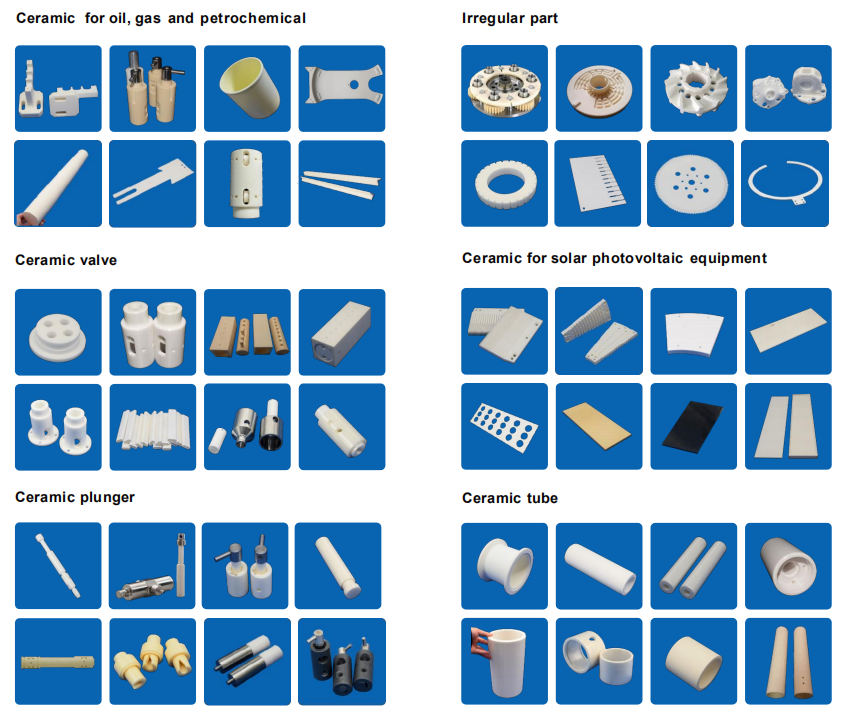

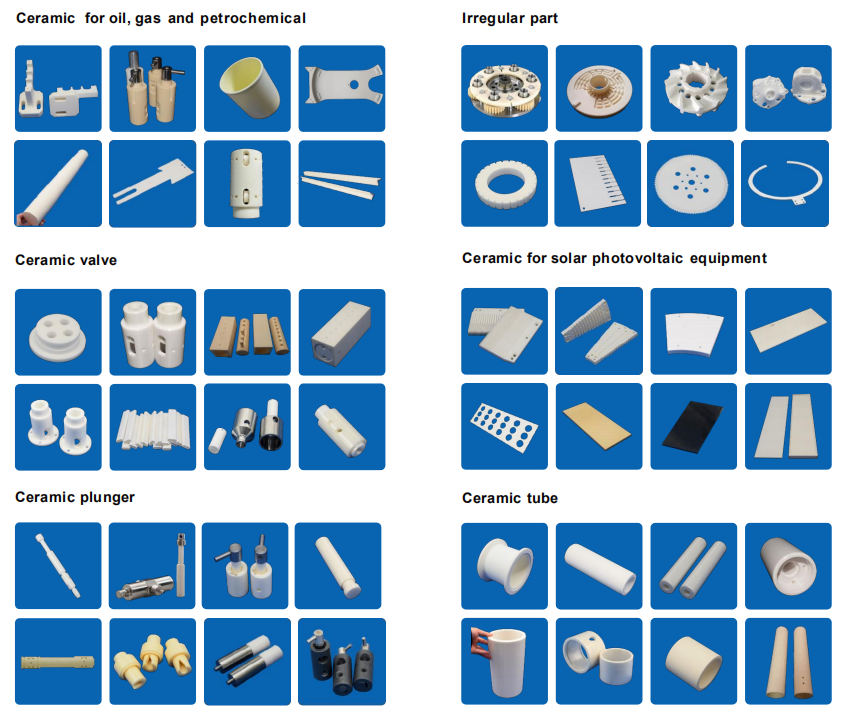

Mingrui Ceramics, as China’s TOP3 advanced ceramic supplier, mainly produces dry pressing, cold isostatic pressing and injection molding. In ceramic production, some ceramic parts are suitable for dry pressing, while some ceramic parts are suitable for casting process. In fact, casting Process and dry pressing process are also two different production and processing methods.

Advanced ceramic structures made of alumina and zirconia.

Now Mingrui Ceramics will introduce the difference between ceramic casting process and dry pressing process.

Casting process:

The ceramic raw material is made into a slurry, continuously stretched and extruded on a roller, and then passed through a mold to shape it. This process is suitable for the production of larger, thin and wide ceramic plates, such as sanitary ware, building decoration materials, etc.

Dry pressing process:

The ceramic raw materials are crushed and mixed, then put into a mold, and pressed with high pressure. This process is suitable for the production of small, simple-shaped ceramic products, such as tea sets, tableware, lamp decorations, etc.

Therefore, the difference between the casting process and the dry pressing process in ceramic production mainly lies in the applicable product types and processing methods.

Both the ceramic casting process and the dry pressing process are common methods of manufacturing ceramic products, and their differences are as follows:

The process principle is different: the casting process stretches and extrudes the ceramic slurry on the roller, and then uses the mold to form; while the dry pressing process puts the ceramic powder into the mold and forms it under high pressure.

The scope of application is different: the casting process is mainly suitable for the production of large-area, thin and wide ceramic plates, such as sanitary ware, building decoration materials, etc.; while the dry pressing process is suitable for the manufacture of small, simple-shaped ceramic products, such as tea sets, Tableware, lighting, etc.

The complexity of the process is different: Compared with the dry pressing process, the tape casting process requires more preparation procedures and equipment, so the complexity is also higher.

The cost and output are different: although the production efficiency of tape casting process is lower than that of dry pressing process, the quality stability of its products is higher, and more refined and high-grade products can be produced. However, due to its complex equipment and process, its production cost is also relatively high.

Therefore, which process to choose should be selected according to product demand and market demand, as well as the production conditions and technical level.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730