Ceramic pin is a positioning pin made of ceramic material, which has the advantages of high hardness, high wear resistance, high chemical stability and high temperature resistance. They are commonly used in mechanical applications requiring high strength, precision and durability, especially in high temperature, high pressure and corrosive environments.

Ceramic pins are widely used in aerospace, automotive, electronics, medical equipment and other fields, such as bearings, seals and supports for gas turbines and engines, manufacturing high-precision abrasives and cutting tools, and manufacturing various electronic devices and sensors, etc. . Compared with metals, ceramic pins have a lower coefficient of thermal expansion and higher rigidity, which makes them more stable and reliable under high temperature conditions.

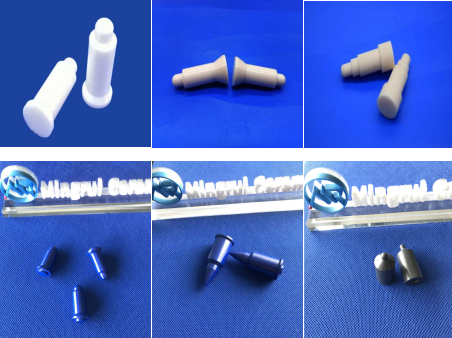

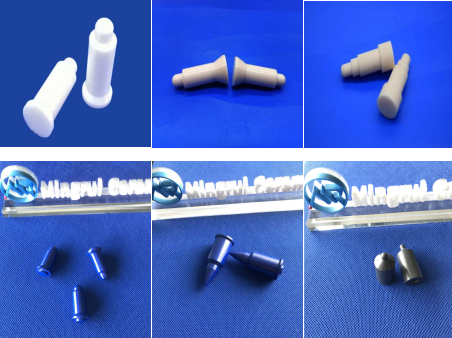

Alumina and Zirconia Ceramic Pins

The commonly used materials of ceramic pins produced by Mingrui Ceramics are alumina, zirconia, silicon carbide and silicon nitride. The characteristics and advantages of these four types of ceramic pins are introduced below.

1. The characteristics and advantages of alumina ceramic pins include:

Features of alumina ceramic pins:

-

High hardness and wear resistance, smooth surface

-

Good thermal stability, not easily affected by high temperature

-

Good corrosion resistance, will not be corroded by acid, alkali and other chemical substances

Advantages of alumina ceramic pins:

-

Lightweight, rigid, and resistant to deformation for high-precision work

-

High density, dense structure, high tensile strength

-

relatively low cost

Application of alumina ceramic pins:

Alumina ceramic pins are widely used in various mechanical equipment, such as automotive, aerospace, electronics, chemical and other fields, and are often used in high-speed, high-temperature, high-pressure, high-precision mechanical components such as bearings, valves, valves, pumps, and transmissions. In addition, it is also used in food processing, medical equipment, semiconductor manufacturing and other industries.

2. The characteristics and advantages of zirconia ceramic pins include:

Features of Zirconia Ceramic Pins:

-

High hardness and strength, smooth surface

-

Good abrasion resistance, excellent compressive, bending and tensile properties

-

Good thermal stability, not easily affected by high temperature

-

Good corrosion resistance, will not be corroded by acid, alkali and other chemical substances

Advantages of Zirconia Ceramic Pins:

-

High durability, high wear resistance, suitable for occasions that require high strength and reliability

-

High density, dense structure, high tensile strength

-

Not easy to deform, not easy to break

Application of zirconia ceramic pins:

Zirconia ceramic pins are widely used in high-speed, high-temperature, high-pressure, high-precision and other mechanical equipment, such as automotive, aerospace, electronics, chemical and other fields. Commonly used in high load components such as bearings, valves, valves, pumps, transmissions, cutters and high pressure injection pumps. On production lines, zirconia ceramic pins can also be used in industries such as manufacturing electronic components, semiconductor manufacturing, and food processing.

3. The characteristics and advantages of silicon carbide ceramic pins include:

Features of silicon carbide ceramic pins:

-

High hardness and high wear resistance, smooth surface

-

Good resistance to high temperature, high pressure, corrosion and thermal shock

-

High density, dense structure, high tensile strength

Advantages of silicon carbide ceramic pins:

-

With high durability and high wear resistance, it is suitable for occasions that require high strength and reliability

-

Good insulation performance, not easy to conduct electricity, and has good anti-static performance

-

Not affected by chemicals such as oxidants and acids, good corrosion resistance

Applications of silicon carbide ceramic pins:

Silicon carbide ceramic pins are widely used in various mechanical equipment, such as automotive, aerospace, electronics, chemical and other fields. Commonly used in high-speed, high-temperature, high-pressure, high-precision mechanical parts such as bearings, valves, valves, pumps, and transmissions. In addition, there are applications in the solar energy, semiconductor and lighting industries, such as infrared heaters and LED substrates.

4. The characteristics and advantages of silicon nitride ceramic pins include:

Features of silicon nitride ceramic pins:

-

High hardness and high wear resistance, smooth surface

-

Good resistance to high temperature, high pressure, corrosion and thermal shock

-

High density, dense structure, high tensile strength

Advantages of silicon nitride ceramic pins:

-

With high durability and high wear resistance, it is suitable for occasions that require high strength and reliability

-

Has high strength, stiffness and toughness, with excellent mechanical properties

-

Not affected by chemicals such as oxidants and acids, good corrosion resistance

Applications of silicon nitride ceramic pins:

Silicon nitride ceramic pins are widely used in various mechanical equipment, such as automotive, aerospace, electronics, chemical and other fields. Commonly used in high-speed, high-temperature, high-pressure, high-precision mechanical parts such as bearings, valves, valves, pumps, and transmissions. In addition, there are also applications in the solar energy, semiconductor and optoelectronic industries, such as LED substrates, solar cells and semiconductor devices.

The advantages of ceramic pins include high hardness, high wear resistance, high chemical stability and high temperature resistance. They are commonly used in sealing, support and transmission applications in high temperature, high pressure and corrosive environments. Ceramic pins are also frequently used in the manufacture of abrasive and cutting tools, as well as in high-tech applications such as medical devices, electronics and aerospace components.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730