Advanced ceramics use refined high-purity products as raw materials, which are different from traditional ceramics in chemical composition, internal structure, performance and use efficiency. Advanced ceramics have a variety of excellent and unique properties, and their application in automobiles can reduce the quality of the vehicle itself, improve the thermal efficiency of the engine, reduce oil and gas pollution, reduce exhaust pollution, and improve the life of wearing parts.

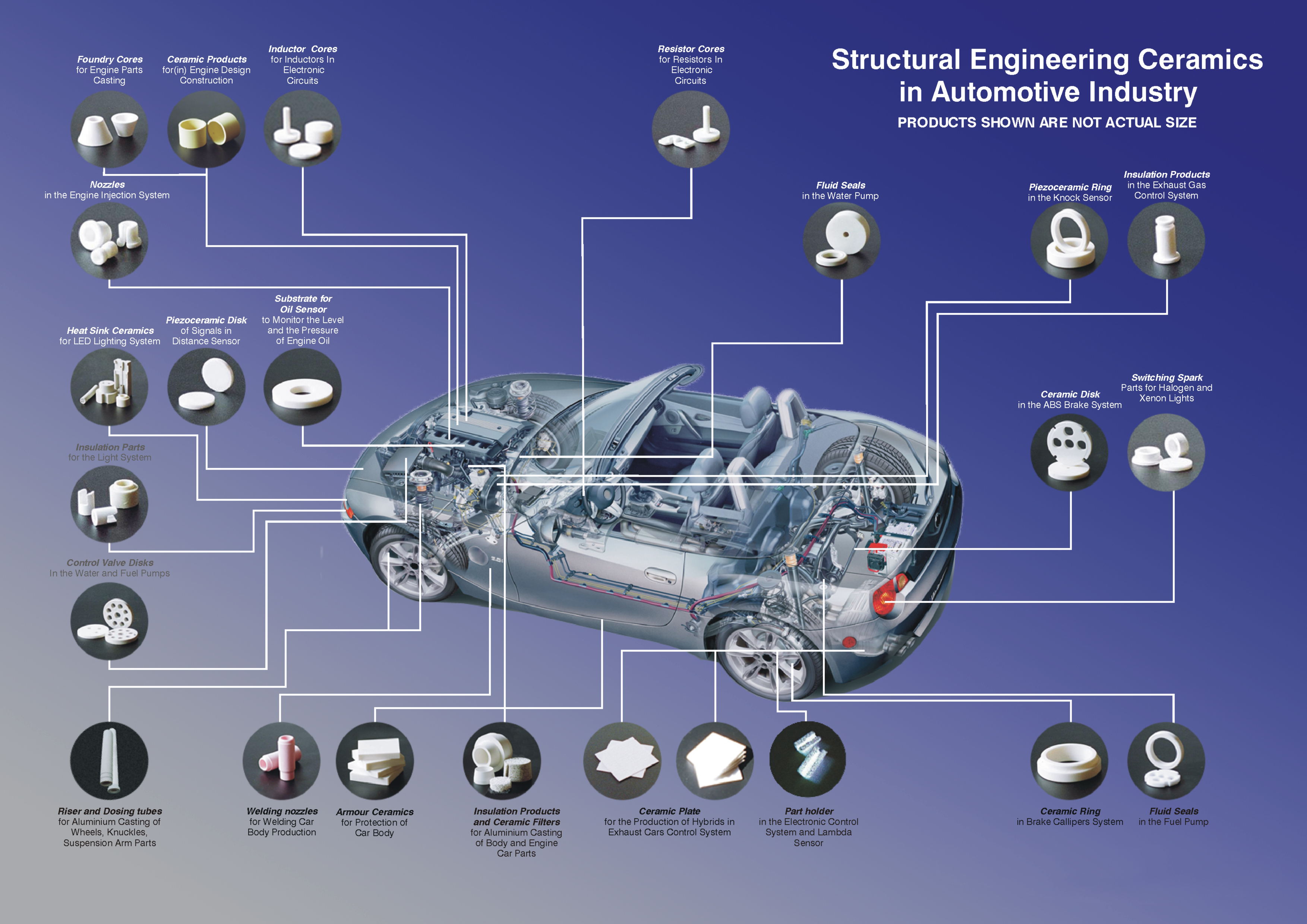

application of advanced ceramics in automobiles industry(Click for larger image)

As a professional advanced ceramics manufacturer, Mingrui Ceramics will introduce the application of 4 kinds of advanced ceramics in automobiles.

Alumina ceramics

Alumina ceramics are also called high-alumina ceramics. The raw material is industrial alumina. The preparation method is to add a small amount of additives to industrial alumina, and then make billets and sinter them. Products that require high surface roughness and precision should also be used. Grinding and polishing. The strength of alumina ceramics is greater than that of ordinary ceramics; the hardness is very high, second only to diamond, boron carbide, cubic boron nitride and silicon carbide, and it has good wear resistance; excellent high temperature resistance, and minimal creep; corrosion resistance Strong resistance; good insulation properties.

The excellent high temperature and dielectric properties of alumina ceramics make it suitable for making spark plugs for internal combustion engines; good wear resistance can ensure that the produced pistons can be processed to a relatively high precision and roughness.

Zirconia ceramics

Zirconia ceramics are resistant to wear, high hardness, low noise, impact resistance, easy to provide constant quality of use, and long service life. Zirconia ceramic oxygen sensors have high mechanical properties and reliability. As a component of purifying exhaust gas, it can be used to determine the concentration of O2 in the exhaust gas of a car, and then feed the measurement back to the engine air supply and fuel supply system. Keep the fuel completely burnt. Since all phases of this ceramic material are fully cubic stabilized zirconia, tetragonal zirconia and partially stabilized mixed monoclinic, the mechanical properties during use are excellent and the heat generated by friction is reduced.

Many devices, parts and small devices used in automobiles can also be made using zirconia ceramics. Such as electronic buzzer, ultrasonic vibrator, heat-absorbing glass, photocell, oil plug ring, oil-water seal, etc.

Silicon Nitride Ceramics

Silicon nitride ceramics have abundant raw materials and good processing performance. The main performance characteristics are high strength, good chemical stability, good temperature resistance, wear resistance, insulation, and high product precision. The preparation methods mainly include reaction sintering method and hot pressing sintering method.

Using silicon nitride materials to manufacture engines, the operating temperature can theoretically be increased to about 1370 ° C. The increase in temperature results in better combustion, higher engine thermal efficiency, and lower exhaust pollution. Reaction sintered silicon nitride can be used to manufacture pump mechanical seal rings, high temperature bearings, valves and other parts.

Silicon carbide ceramics

Silicon carbide ceramics are made of silicon carbide powder (quartz, carbon and wood chips are put into an electric arc furnace and synthesized at a high temperature of 1900~2000 ° C) by powder metallurgy through reaction sintering and hot pressing sintering process. The biggest features of silicon carbide ceramics are high temperature and high strength (the flexural strength at 1400°C remains at a high level of 500~600MPa), strong thermal conductivity, good thermal stability, wear resistance, corrosion resistance, and creep resistance.

Silicon carbide ceramics can be used to make rocket tail nozzles, nozzles for pouring metal, thermowells, gas turbine blades, bearings and other parts.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730