Analysis of the characteristics and status quo of Advanced Ceramic 3D Printing Technology

As a structural material, advanced ceramics are widely used in aerospace, industrial manufacturing and biomedicine due to its high bending strength, good creep performance, high hardness and high temperature resistance. However, ceramics prepared by traditional methods are generally difficult to process and difficult to prepare products with complex shapes. The emerging 3D printing technology has great development potential in the field of high-performance ceramic forming and manufacturing. It is expected to break through the technical bottleneck of traditional ceramic processing and production, open up new ways for the application of advanced ceramic key parts, and provide solutions for traditional manufacturing problems and challenges, new possibilities.

1. Advanced Ceramic 3D printing technology

The emergence of 3D printing technology (also known as additive manufacturing) breaks through the constraints of traditional manufacturing technology and provides a possibility for the manufacture of complex structural parts. Compared with the traditional subtractive and equivalent material manufacturing methods, the additive manufacturing technology has the characteristics of not increasing the cost and without the need for molds to produce special-shaped products. Its biggest advantage is that it can prepare complex structures that cannot be prepared by traditional processing methods, and realize the structured design of materials, so as to efficiently realize the integration of materials and structures, and the integration of structure and functions.

Advanced Ceramics 3D printing technology is an advanced manufacturing technology that produces ceramic parts with three-dimensional complex structures by layer-by-layer manufacturing and superimposition of discrete materials. It has the advantages of high material utilization, strong manufacturing flexibility, and high degree of digitization. It is suitable for small batches, complex structures and ceramic parts manufacturing.

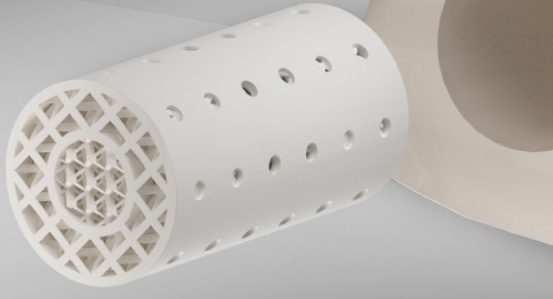

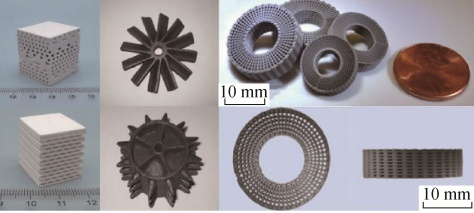

3D printing complex ceramic structures (photo source: Journal of The Chinese Ceramic Society)

2. Mainstream ceramic 3D printing technology

The current mainstream ceramic 3D printing technologies include: Fused Deposition Modeling (FDM), Light Curing 3D Printing (SLA), Ink Direct Writing (DIW), Powder Bed Laser Sintering (SLS), etc.

1.1 Fused Deposition Modeling Technology (FDM)

FDM technology uses spinnerets mixed with ceramic powder as raw materials, melts the polymer materials in the spinnerets at a temperature above the melting point of the polymer, and extrudes the nozzles. The extruded ceramic polymer composite material is cooled and solidified.

FDM technology equipment has low raw material cost, high material utilization rate, and abundant optional materials, but the accuracy is low, it is difficult to construct components with complex structures, the strength in the direction perpendicular to the cross section is low, and the molding speed is slow.

1.2 Light curing 3D printing technology (SLA)

Light-curing 3D printing technology is considered to be the most famous and popular 3D printing technology, and has been widely used in the world. It is to mix ceramic powder with photosensitive resin and other additives to form photosensitive ceramic paste. Ultraviolet light is under the control of the program. Scanning the paste point by point initiates cross-linking of the photosensitive resin, so that the paste is cured and formed. The slurry is cured for one layer, the forming table is lowered to a certain height to replenish the slurry, and the new layer of slurry continues to be cured under the action of ultraviolet light. The ceramic slurry is solidified layer by layer to obtain a ceramic green body, and the ceramic material is obtained after degreasing and sintering.

SLA technology has the advantages of fast forming rate, good surface quality and high dimensional accuracy. Compared with other technologies, SLA technology is suitable for preparing small parts with high precision and complex shapes. The technology is not limited to ceramic substrates (alumina, zirconia, calcium phosphate, etc.), and the density can be as high as 96% or more.

1.3 Ink direct writing molding (DIW)

Direct ink writing (DIW) refers to mixing ceramic powder with various organic substances under program control to make ceramic ink, which is then printed on the forming plane by a printer to form a ceramic body.

The configuration of the ceramic ink is the key. It is required that the ceramic powder can be dispersed well and uniformly in the ink, and have suitable viscosity, surface tension and conductivity, as well as a faster drying rate and as high a solid content as possible. DIW technology requires degreasing and sintering in a high-temperature furnace. It has the advantages of fast forming speed and wide range of forming materials. It has great advantages in preparing dark ceramic products, but the surface accuracy of the products is poor and the density is low.

1.4 Selective laser sintering technology (SLS)

Selective laser sintering technology (SLS) is to spread ceramic powder and other low melting point powders on the powder bed, and the laser moves according to the set path under the control of the program. The low melting point powder is melted under the action of a laser and the ceramic powder is connected. After one layer is completed, the forming table is lowered to a certain height, and the three-dimensional entity is finally obtained by stacking layer by layer.

SLS has the advantages of fast forming rate and large forming size span. However, due to the high content of organic polymer binder, the resulting green body has a low density and is loose and porous. Therefore, subsequent treatments are usually required to increase the density, such as isostatic Pressure treatment and impregnation technology.

3. Advanced Ceramics materials for 3D printing

The Advanced Ceramics materials that have been developed for 3D printing mainly include the following:

♦Alumina ceramics: the most widely used industrial ceramics at present, its temperature resistance is as high as 1700℃, and its performance is still good at high temperatures. In the technology of ceramic 3D printing materials, the modified ceramic powder materials are used for 3D printing. The production time is short, the cost is low, the processing is convenient, and the operability is strong. Therefore, alumina ceramic 3D printing materials are widely used in construction and aviation. Aerospace and electronic products and other fields.

♦Zirconium oxide ceramics: It has phase transformation toughening and micro-crack toughening, so it has high strength and toughness. It is known as "ceramic steel". High hardness, high strength and high toughness ensure that zirconia ceramics are better than other structures Ceramics have incomparable wear resistance; at the same time, polished zirconia ceramics have a metal-like luster and can be blended with different colors, so they are very popular in the field of jewelry luxury goods.

♦Silicon carbide ceramics: Silicon carbide (SiC) ceramics have high temperature mechanical properties such as high bending strength, excellent oxidation and corrosion resistance, high wear resistance and low friction coefficient. SiC ceramics have the best high-temperature mechanical properties (strength, creep resistance, etc.) among known ceramic materials, and their oxidation resistance is also the best among all non-oxide ceramics.

♦Porous silicon nitride ceramics: Porous silicon nitride ceramics (Si3N4) combine the advantages of both porous ceramics and Si3N4 ceramics, with good thermal conductivity, uniform permeability, and stable physical and chemical properties. In terms of 3D printing porous silicon nitride ceramics, Weng Zuohai of Northwestern Polytechnical University used high-purity silicon powder with a particle size of 7.2μm as raw material and dextrin as a binder to prepare Si3N4 powder with a particle size of less than 200μm. material.

♦Titanium carbide silicide ceramics: Titanium carbide silicide ceramics (Ti3SiC2) have a layered hexagonal crystal structure and are widely used in biology and medical treatment. Using 3D printing technology to prepare Ti3SiC2 ceramics can completely overcome the shortcomings of high cost, time-consuming, and poor flexibility.

4. Current status and development characteristics of Advanced Ceramics 3D printing

Relevant media conducted market research on 96 Advanced Ceramics 3D printing companies. The survey results showed that the ceramic 3D printing market will generate approximately US$154 million (approximately 993 million yuan) in revenue in 2020. Through a proprietary forecasting model, multiple impacts have been integrated. Coefficient, the ceramic 3D printing market is expected to grow from 154 million U.S. dollars in 2020 to more than 3.4 billion U.S. dollars (approximately 21.9 billion yuan) in 2030.

♦Industrial-grade ceramic 3D printing technology and equipment have a high threshold and high cost, which requires research from various aspects such as raw material sintering and post-processing;

♦Printing efficiency needs to be further improved, and the production process is simplified and automatically integrated;

♦Light-curing 3D printing technology is currently the best ceramic printing technology with good molding effects;

♦Currently, 3D printed ceramic products still have problems such as unsatisfactory surface quality and low precision. You can start with the physical and chemical laws of material molding to study more new ceramic 3D printing technologies;

♦For new applications, more high-performance ceramic materials must be developed.

5. Summary

At present, Advanced Ceramics 3D printing technology and its applications have received extensive attention from scientific research institutes and the industry, and are developing rapidly, involving many ceramic material systems and application fields. The emerging 3D printing has great development potential in the field of high-performance ceramic forming and manufacturing. Advanced Ceramics 3D printing is expected to break through the technical bottleneck of traditional ceramic processing and production. Advanced Ceramics 3D printing opens up new ways for the application of ceramic key parts and solves traditional manufacturing problems. And challenges provide new possibilities for Advanced Ceramics 3D printing.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730