As far as ceramic technology is concerned, the sintering technology of ceramic rods refers to the process of putting the original ceramic body into a kiln to undergo a series of physical and chemical changes and then forming ceramic rods.

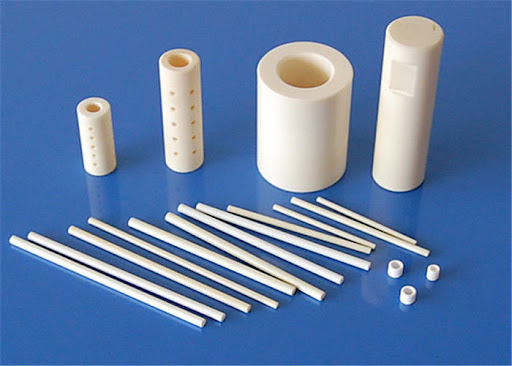

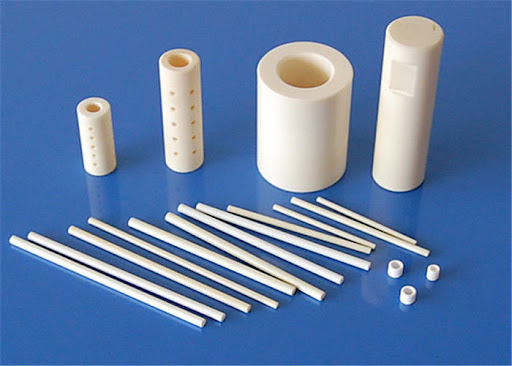

Ceramic Rods

The sintering of ceramics is indeed not an easy task. For example, temperature, atmosphere, pressure, etc. are all factors that affect the sintering of the finished product. Because for firing, different temperatures will cause the embryo to undergo different physical changes, and if the temperature is not well grasped, it may be impossible for the kiln to form. Of course, the quality of the billet, that is, its chemical composition, will also affect the finished product. Different muds, kaolin and watery kaolin, even if they have similar crystal structures, the dehydration reaction produced during the heating process is also different. .

The embryo body has to go through several stages of low temperature, medium temperature and high temperature during the firing process. The low temperature stage is the evaporation of water, the medium temperature stage is the oxidation decomposition and crystal transformation stage, and the high temperature stage is the final vitrification into porcelain. When the temperature is low, it is required to say that the moisture entering the kiln is low. In this way, it is easy to remove the remaining moisture. It will not be like when the moisture entering the kiln is high, the moisture may vaporize and cause unnecessary destructive power to crack the product and cause economic losses.

In the middle temperature process, many physical and chemical changes will occur, oxidation and decomposition reactions will occur, and quartz will undergo crystal transformation. In the process of dehydration, its temperature will be related to the degree of dispersion of the raw material itself. The finer the raw material, the lower its dehydration temperature. In terms of oxidation, it is specifically the oxidation of carbon, sulfide and some organic substances. If we do not completely remove the organic matter and carbon at this time, after the embryonic body closes the stomata in the later stage, it will very likely cause a series of problems such as smoke and bubbles. In the process of decomposition, all CO2 must be escaped before sealing, otherwise it will cause problems such as blastocysts. The most important thing in the high temperature stage is the formation of a liquid phase, because the liquid phase can promote the formation of new silicate crystals.

The sintering technology of ceramic rods includes both rapid sintering and sintering energy saving. This requires us to master the operating points of the kiln, and also to reduce the sintering temperature. The most important thing is to use the waste heat, which will greatly improve Thermal efficiency.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730