Zirconia ceramics are mainly divided into precision zirconia ceramics and ordinary zirconia ceramics. Many people do not know zirconia ceramics very well. As a professional manufacturer and supplier of zirconia ceramics, Mingrui Ceramics today specifically introduces the service life of zirconia ceramics.

In fact, Zirconia ceramics have many advantages. There are more and more products processed by zirconia ceramics. In industrial production, many companies need to use zirconia ceramic parts. Compared with other materials, zirconia ceramic parts have better performance. So how long is the service life of zirconia ceramics?

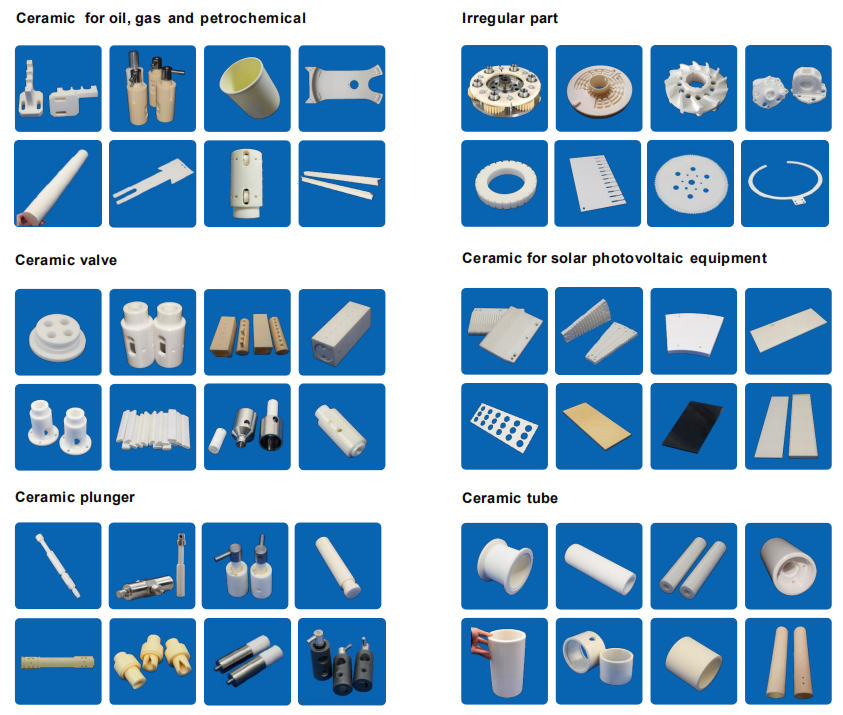

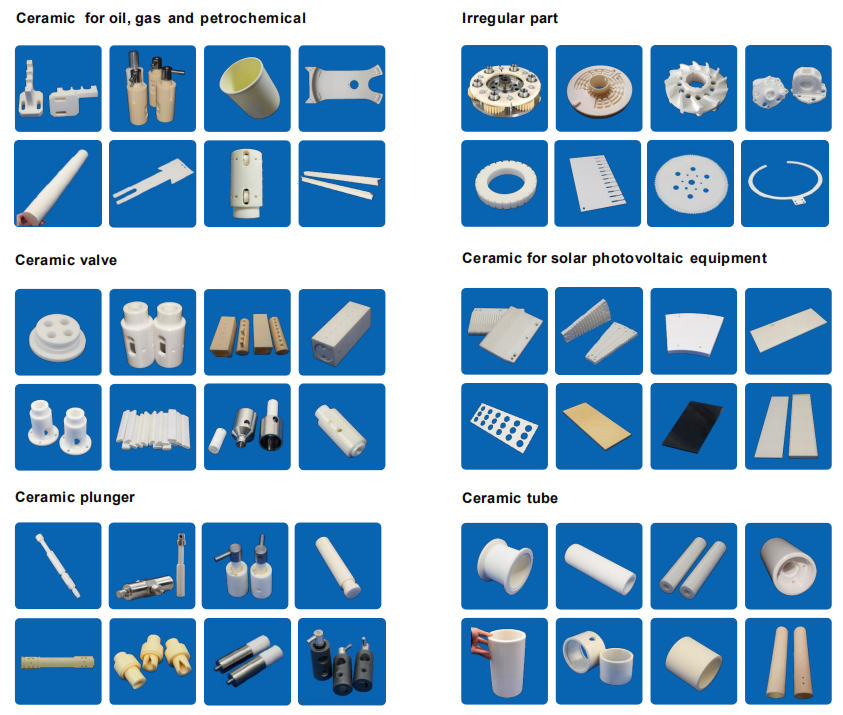

Zirconia Ceramic Parts and Components

Zirconia ceramics can generally be used for one year. Because of the death of nitrifying bacteria, although part of the corpses will be washed away with the flow of water, some of them remain in the nitrifying bacteria gaps and slowly accumulate to the back to block the gaps. The parasitic effect of the ceramic ring will gradually decrease, so it needs to be replaced regularly.

Over time, you will find the color of "ceramics" is "white"-"yellow"-"deep yellow". This is because impurities in the water have blocked the surface voids of "ceramics", even for cleaning. Satisfactory results will be achieved!

Ordinary alumina ceramics are classified into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain and other varieties according to different Al2O3 content. Sometimes those with 80% or 75% Al2O3 content are also classified as ordinary alumina ceramic series. Among them, 99 alumina porcelain materials are used to make high-temperature crucibles, refractory furnace tubes and special wear-resistant materials, such as ceramic bearings, ceramic seals and water valve discs; 95 alumina porcelain is mainly used as corrosion-resistant and wear-resistant parts; 85 porcelain Because it is often mixed with some talc to improve the electrical performance and mechanical strength, it can be sealed with metals such as molybdenum, niobium, and tantalum, and some are used as electrical vacuum devices.

When it comes to ceramic materials, it is easy for everyone to associate it with fragility, but in fact, because alumina ceramics are added with special materials, their physical properties are much better than traditional ceramics. Qualified alumina ceramic products have a high level of hardness and will not be damaged under extrusion and collision.

The service life of the above zirconia ceramics is introduced here. Zirconia is said to never wear. The specific service life needs to be analyzed and tested according to the use environment to determine the service life of the product.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730