Industrial ceramic materials can be divided into many categories. Industrial ceramic parts manufactured through strict production processes have excellent performance and are now widely used in various industries. Next, Mingrui Ceramics will introduce the development and application of industrial ceramic materials.

Industrial ceramics are high-performance materials manufactured through strict composition and production process control according to the required product performance. They are mainly used in high temperature and corrosive medium environments. It is one of the most active areas of modern material science development. There are two main areas of industrial ceramic materials: structural ceramics and functional ceramics.

1. Structural ceramics

Compared with metal materials, the biggest advantages of industrial ceramics are excellent high temperature mechanical properties, chemical corrosion resistance, high temperature oxidation resistance, wear resistance, and small specific gravity (about 1/3 of metal). Therefore, it gradually replaces expensive ones in many occasions. Ultra-high alloy steel may be applied to occasions where metal materials are simply incapable, such as engine cylinder liners, bearing bushes, sealing rings, ceramic cutting tools, etc. Structural ceramics can be divided into three categories: oxide ceramics, non-oxide ceramics and glass ceramics.

2. Oxide ceramics

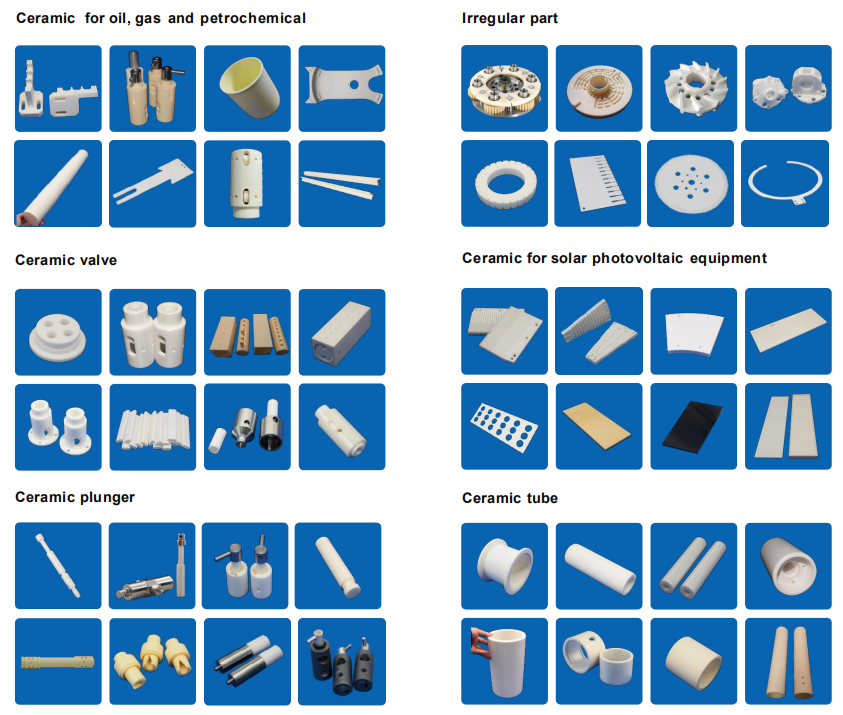

Mainly include alumina ceramics and zirconia ceramics. Alumina ceramics and oxide ceramics are mainly used in industrial ceramic knives, industrial ceramic rods, industrial ceramic plates, industrial ceramic sheets, industrial ceramic tubes, industrial ceramic rings, industrial ceramic pumps, industrial ceramic shafts, industrial ceramic plungers, industrial ceramic nozzles, Industrial ceramic crucible, industrial ceramic gear, industrial ceramic valve core, industrial ceramic screw, etc.

3. Non-oxide ceramics

Silicon-containing non-oxide ceramics have excellent high-temperature corrosion resistance and oxidation resistance, so they have always been the most important materials for ceramic engines and have now replaced many ultra-high alloy steel parts. It has important strategic significance in energy utilization and environmental protection. Non-oxide ceramics are also widely used in ceramic cutting tools. Compared with oxide ceramics, its cost is higher, but the high temperature toughness, strength, hardness, creep resistance is much better, and the tool life is long, and the allowable cutting speed is high, so it occupies an increasingly important position in the tool market. Its application areas also include lightweight non-lubricated ceramic bearings, seals, kiln furniture and grinding balls.

4. Functional ceramics

Functional ceramics are ceramics with optical, electrical, thermal or magnetic properties, and have a very high degree of industrialization. The following is a brief introduction to the performance of several types of main functional ceramics.

Industrial ceramic materials have a very wide range of conductivity, from insulators to semiconductors and superconductors. Most ceramics have excellent electrical insulation properties and are therefore widely used in electrical insulators. Semiconductors are divided into electronic and ionic semiconductors. Transistor integrated circuits are represented by electronic semiconductors. The main products of ionic semiconductors are oxygen sensors (mainly used to measure the combustion efficiency of engines or the oxygen concentration in molten steel), oxygen pumps (to obtain pure oxygen from the air) and fuel cells. Typical ceramic superconductors are yttrium-barium-copper-oxygen series materials, which have been widely used in the fields of computers and precision instruments.

Most industrial ceramics have excellent dielectric properties, manifested in their high dielectric constant and low dielectric loss. One of the main applications of dielectric ceramics is ceramic capacitors. Piezoelectric ceramics are extremely versatile, with products such as pressure sensing elements and ultrasonic generators.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730