With many years of experience in the production and processing of precision ceramics, Mingrui Ceramics today summarizes the four major applications of precision ceramic materials in the industry:

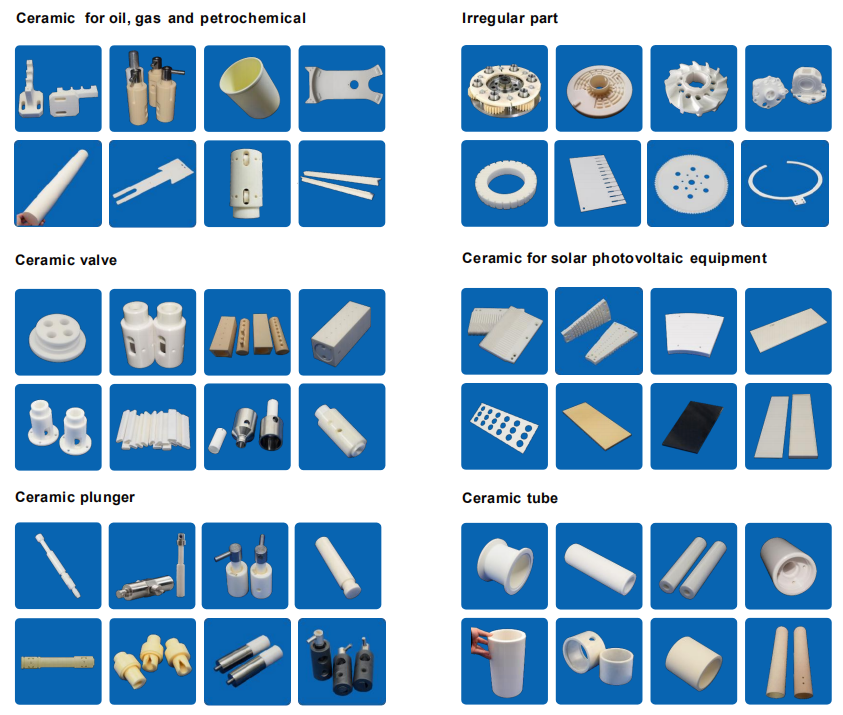

Precision Ceramic Structural Parts Made by Mingrui Ceramics

1. Used to improve the mechanical strength of ceramic materials

Precision ceramic structural parts are materials characterized by mechanical properties such as strength, stiffness, toughness, wear resistance, hardness, and fatigue strength.

2. Used to improve the superplasticity of ceramic materials

Only when the particle size of the ceramic powder is small to a certain extent, can the 2113 superplastic behavior be produced in the ceramic material. The reason is that the nanometerization of the crystal grains can help the relative slip between the crystal grains and make the material have plastic behavior.

The superplasticity of nanoceramics has potential applications in electronics, magnetism, optics, and bioceramics. The possible low-temperature superplasticity, ductility and high fracture toughness of nano-ceramics will make it have the excellent characteristics of both ceramics and metals (such as high strength, high hardness, high toughness, high temperature resistance, corrosion resistance, easy processing 5261 Etc.) new structure and functional materials have infinite and broad application prospects in many 4102 fields such as aviation precision ceramics, medical precision ceramics, electronic precision ceramics, machinery, information and so on.

3. Used in the preparation of electronics

The reason why nano-ceramic powders are widely used in the preparation of electronic ceramics is that the nanometerization of ceramic powder grains will cause a large increase in the number of grain boundaries. When the grain size in the ceramic is reduced by an order of magnitude, the surface area of the grains The volume of the grain boundary is also increased by a multiple of the phase 1653 response.

4. Used in the preparation of ceramic tool knives

The emergence of nanotechnology and the industrial production of nano-powders have made the preparation of cermet knives a reality.

The hardness of precision ceramic knives is very high, and some of them are used in industry to cut metal, and even can be used to cut steel. As a new type of precision ceramic material, structural ceramics is a ceramic blade. Its unique performance has broken people's radical impression of ceramics, and it is gradually being recognized by the society and used in more and more engineering fields.

Ceramic knives are generally made of zirconia precision ceramic materials with a hardness of 9, which is second only to the hardest material in the world ─ ─ diamond (10). Everyone knows that the harder the material, the sharper the blade. , But sharpness also comes at a price, because it is hard, it is relatively brittle, and low toughness can not cut hard objects, which is determined by the characteristics of the material.

Compared with industrial ceramic knives (for trimming plastic flash) and civilian ceramic knives (for cutting fruits), there is not much difference in material and structure. But they can't cut hard things. This thing is wear-resistant and can be used for a long time without grinding.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730