As a member of a large ceramic family, alumina ceramics has many forms in many industries, including high-end manufacturing and mass industrial foundations. As the leader in the family, functional ceramics are widely used in high-end manufacturing. Everyone complained that its appearance fee was very expensive, but ignored the motivational production process. Today, Mingrui Ceramics leads everyone to understand the price of high-quality alumina materials.

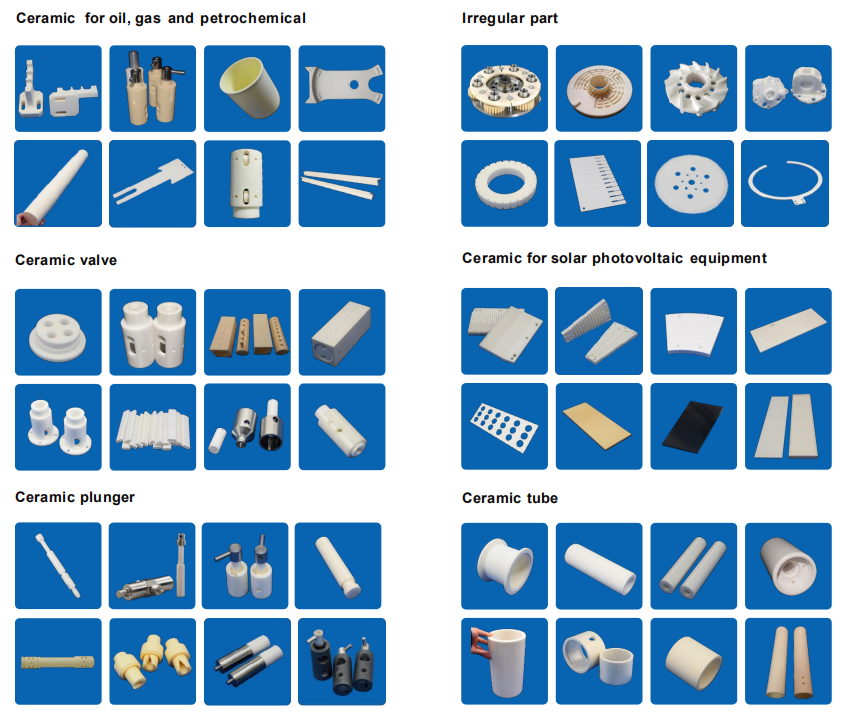

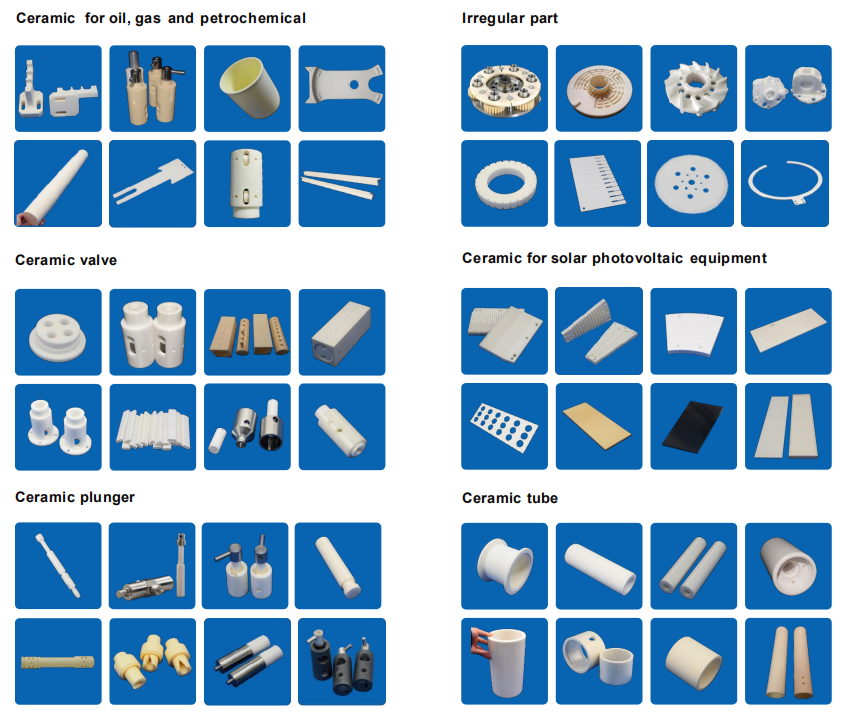

Alumina Ceramic Structural Parts

1. Like other materials, bauxite is widely distributed all over the world. However, the first step of China's alumina mines is to explore in the following four areas, and not all areas can be mined. However, the aluminum to silicon ratio of bauxite is evaluated as "rich ore" or "lean ore". Unfortunately, the current reserves of bauxite are very large and the quality of bauxite is very low. The import volume of bauxite is 60% of that of foreign countries. The distribution of bauxite in the world.

2. At present, the mainstream production process of Guizhou processing is called Bayer process. The main process flow is as follows: A large amount of lime, lye and waste residue containing alkaline "red mud" are consumed in the alumina materials production process. Environmental treatment is troublesome. With the strengthening of environmental protection laws and regulations, many manufacturers with backward technology and high energy consumption have gradually been eliminated, which has also led to high prices.

3. The composition of China's bauxite was purified and analyzed. The alumina materials content in the raw ore is 50%. Purity is difficult to play the special function of alumina materials, which is reasonable, but some minerals have their own functions &40; such as large specific surface area and relatively low price&41; they can be used in industries such as desiccant and oil-absorbing paper, so alumina ceramics need further Purification. Purification is a delicate chemical process. Although there are two decimal places after the decimal point, the cost is huge, which is why the price of high-purity alumina remains high. Conversely, if we know the key, we will also reduce the purchase of low-quality "high-purity alumina."

4. Impurity elements in alumina purification process

①Si impurity Si exists in the bauxite mat in the form of silicate. It will be dissolved by alkali and alumina materials. Therefore, the first step of the Bayer process is desiliconization, the undesiliconized sodium aluminate solution & 40; the crude solution & 41; in which the silica content is about 4-6GL, and the silicon index is between 20-30. After desiliconization, silicon The content can be reduced to 0.12 grams to 0.1g&&40; silicon index 1000~1200&41;. Further purification can reach 0.024gl, click here on the blackboard: the higher the purity, the more complicated the process and the higher the price.

②The main minerals damaged by Fe alumite mats are hematite 40, Fe2O3 41, pyrite 40, FeS2 41; Fe2O3 in production exists in the red mud in the form of precipitation, and the amount of suspended particles is 3μm. The amount of particles is small; most of them are in the range of 20-30mgL. The general practice is to add a magnet for adsorption and filtration in the fractionation tank. The amount of adsorption and filtration can reach 4-5mgL, and some iron is combined with iron-sulfur compounds. This matter will vary with changes in process control, temperature, dilution, etc. Alumina particles are affected by various factors. It is the main source of iron in the final alumina materials. According to statistics, when the iron content in alumina materials is greater than 0.02%, the quality of alumina materials will decrease.

③ TiCaMg impurities are mainly related to iron ore, and usually the desiliconization step is completed at the same time: 2CaO TiO2 2H2O-> 2CaO*TiO2*2H2O, insoluble in water. CaMg is mainly limestone introduced during the desilication process and can be removed during the desilication process. The NaK impurity in Xi liquor mainly comes from alkaline solution, and it exists in the form of sodium potassium aluminate in liquor. However, a small amount of NaK will be adsorbed in Al&40;OH&41;3. [C] 40. Organic matter 41; the impurities are mainly huxi acid and asphalt mixture. These substances will be filtered out or form sodium oxalate sodium carbonate dissolved in the mother liquor in an alkaline environment.

At present, the main method is combustion oxidation or wet oxidation. How to identify the authenticity of high purity alumina materials? The theoretical purity limit of the above process is 99.99%. If you want to buy 4N alumina, what is its production process? If it is Bayer, you must think carefully. There are 99.9%, 99%, 95% purity on the market. If you can confirm that it is the production basis of that factory, you can judge whether it is true or not. The reason is also very simple. The production line planning of each company is different. Low-purity processes will never produce high-purity alumina. Which is 99.9% alumina? What kind of alumina powder is mixed with limestone? 6. How to obtain 4N5N alumina materials? In the electronics industry, the purity of alumina materials is very high, most of which are precipitated at a rate of 4N. The main processing method is: Put No. 1 aluminum powder and high-purity water into the reactor, and Al-H2O->; Al&;40;OH&;41;3 reacts to produce solid Al&;40;OH&;41;3, which is calcined into alumina. This seems to be a simple method, but it is difficult to control the introduction of impurities during the manufacturing process. Its purity can reach 99.99%. ≫ 2 Hydrolysis of aluminum alkoxide. Aluminum alcohol and aluminum-aluminum-40; or -41; 3 H20-distillation reaction to form high-purity aluminum-40; or -41; 3-2 times high-purity filtered aluminum-40; or -41; 3 H2O-Al-40 ; OH-41; 3-Al2O3. The process is complicated, but the purity can reach 99.999%.

the most important! According to statistics, China's annual import demand for 4N5N alumina materials is 9,000-17,000 tons. At present, the domestic 4N-class production capacity is about 5,000 tons, and the 5N-class production capacity is about 6,000 tons. In other words, the gap between 4N and 5N is 64% and 73%, respectively.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730