When zirconia ceramics are formed by grouting, there are often some defects, such as pores, pinholes, cracks, mud strands, deformation and other defects, so what are the reasons for these defects? Next, Mingrui Ceramics, a manufacturer of precision zirconia ceramics, will analyze the common defects of grouting molding of zirconia ceramics for you.

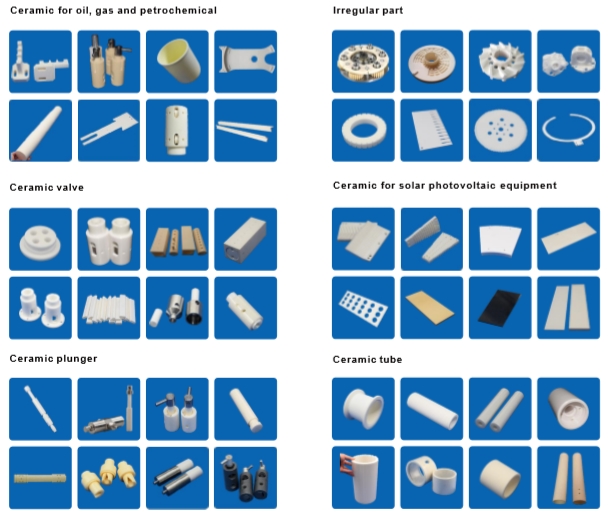

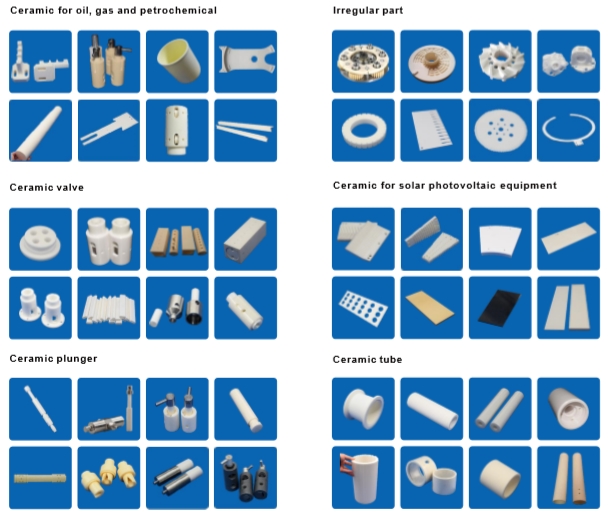

Zirconia Ceramic Precision Structural Parts

1.Stomata and pinholes

The main reasons for the generation of pores and pinholes

(1) There is too little water in the mud, too much viscosity, and poor fluidity, so that the air bubbles in the mud are not easy to discharge.

(2) The mud storage time is too long and the mud temperature is too high, resulting in the mud fermentation; the mud is not stale.

(3) Improper type and amount of electrolyte.

(4) The mud is stirred too vigorously, or the grouting speed is too fast, so that air bubbles are trapped in the mud.

(5) The gypsum mold is mixed with impurities, such as sand or calcium carbonate; the particles of the gypsum used for molding are too coarse, resulting in uneven structure of the model; the surface of the model is stained with dust.

(6) The plaster mold is too dry, too wet, or the temperature is too high.

2. Cracking

The main reasons for cracking are:

(1) The amount of plastic raw materials in the mud is improper, and the particles are too coarse.

(2) The amount of electrolyte is improper, or the mud is not stale, the stirring is uneven, and the fluidity is poor.

(3) The model is wet and dry, and the oily impurities on the surface of the model are not removed before use.

(4) The grouting operation is not good, and the residual slurry is not completely poured, resulting in uneven thickness of the injection parts and inconsistent drying shrinkage.

(5) The injection moulding is too early or too late, and the drying temperature is too high.

3. Deformation

The main reasons for deformation:

(1) The mud is not mixed evenly, resulting in different drying shrinkage.

(2) Too much moisture in the mud results in large drying shrinkage.

(3) Improper operation of pouring the remaining slurry, the thickness of the green body is uneven.

(4) The model is too wet or demolded too early, or the demolding operation is improper, and the wet blank is not leveled and straightened.

(4) Mud strands

The main reasons for the formation of mud wisps:

The viscosity of the mud is high and the fluidity is poor; the working surface of the model is stained with mud droplets; the operation of pouring the remaining mud is improper.

The above is the introduction of common defects in the grouting molding of zirconia ceramics analyzed by metalworking precision zirconia ceramic manufacturers, hoping to provide you with a reference.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730