Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730Structural ceramics stand out among many widely used materials with a long history, and become the choice of more and more industries, so what are the types of structural ceramics?

Structural ceramics stand out among many widely used materials with a long history, and become the choice of more and more industries, so what are the types of structural ceramics?

As there are numerous kinds of structural ceramics, through the summary of the market, this paper summarizes four representative common structural ceramics for your reference.

Alumina and Zirconia Ceramic Structural Parts

First: alumina ceramics

Alumina is second only to silicon oxide in the reserves of alumina on the earth, which makes alumina ceramics cheap and widely used, so it can be called the head of state of structural ceramics.

In the 1930s, Siemens of Germany took the lead in developing alumina ceramics as spark plug insulators for automobiles and then started the application of commercial alumina ceramics.

In the following decades, with the rapid development of the transportation and electronics industry, alumina ceramics have been widely used in the R & D and production of engine sparks and semiconductors.

Second: zirconia ceramics

Zirconia has a special strengthening structure and is the structural ceramic with the best mechanical properties at room temperature. If you drop zirconia ceramics to the ground, not only will not break, but will bounce up, so it is known as ceramic steel in many structural ceramics.

Third: silicon nitride

Silicon nitride ceramics are mainly used in high-temperature structural materials, which have excellent high-temperature strength. Common high-efficiency turbine engine parts, internal combustion engine parts, cutting tools, ceramic bearings, refractories and so on are inseparable from this useful structural ceramic.

At present, there are mass-produced silicon nitride parts and finished products, which can greatly reduce fuel consumption, reduce waste gas pollution and increase output power.

Fourth: silicon carbide

Oxide ceramics and metal materials cannot be used in high-temperature environments, but non-oxide ceramics have the opportunity to do so. Because the thermal conductivity of silicon carbide is higher than that of other structural ceramics, it is quite suitable to be used in high-temperature heat exchangers to recover the heat contained in factory waste gas or wastewater.

These are the four most famous structural ceramics in the industry, all of which have unparalleled excellent properties. From the user’s point of view, reliable and durable structural ceramics are worthy of everyone’s trust and support.

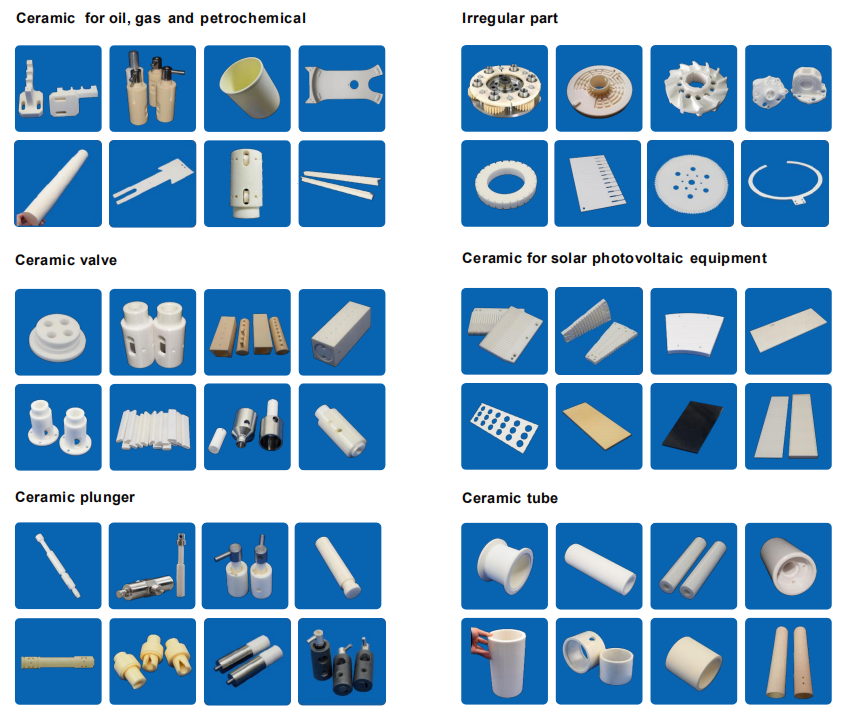

Mingrui Ceramic focus on the custom manufacturing and ultra-precise machining of ceramic structural components, which made of zirconia, alumina, silicon carbide, and silicon nitride. Inquiring today for customizing ceramic parts!

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS