Semiconductor ceramics is a special ceramic material used in semiconductor production, which has the characteristics of high hardness, high strength, high temperature resistance and high corrosion resistance. It is mainly used in high-precision operation and protection under high temperature and high pressure environment in the semiconductor manufacturing process.

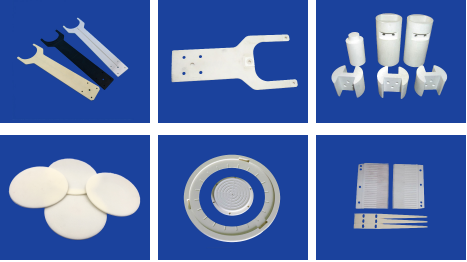

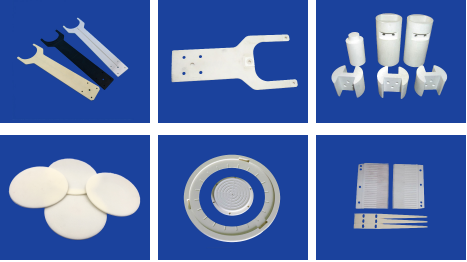

There are many types of semiconductor ceramics, common ones include alumina ceramics, silicon nitride ceramics, zirconia ceramics, and silicon carbide ceramics. These ceramic materials have high hardness, high strength, high heat resistance and corrosion resistance, and are usually made of Parts of various shapes, such as packages, process trays, plates, fixtures, etc., are used in various links in the semiconductor production line, among which ceramic arms are used more.

Some semiconductor ceramic structural parts produced by Mingrui Ceramics

The semiconductor ceramic arm is a mechanical arm made of semiconductor ceramic materials, which is used for automatic operation in high-precision, high-purity, high-temperature and high-pressure environments such as semiconductor production lines.

Semiconducting ceramic arms usually consist of multiple components, including bases, joints, and end effectors. These parts are made of semiconductor ceramic materials, which have high hardness, high strength, high heat resistance and corrosion resistance.

Compared with traditional metal materials, semiconducting ceramic arms have the following advantages:

1、High precision and high repeatability: The semiconductor ceramic arm has extremely high rigidity and stability, which can realize high precision and high repeatability movement.

2、Resistance to high temperature and high pressure environments: Semiconductor ceramic materials have good high temperature resistance and corrosion resistance, and are suitable for scenarios requiring high temperature or high pressure operations in semiconductor manufacturing.

3、Lightweight design and low vibration and noise: The semiconductor ceramic arm adopts a lightweight design, which reduces the impact of the robotic arm on other equipment, and also reduces its own vibration and noise.

4、Customizable design: The semiconductor ceramic arm can be customized according to actual needs to meet the needs of automated operations in different scenarios.

Semiconductor ceramic arms are widely used in wafer handling, dicing and packaging in the semiconductor manufacturing process. They can improve production efficiency, product quality and stability, and are an important part of semiconductor production lines.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730