The most commonly used forming processes in the advanced ceramics industry are dry pressing, cold isostatic pressing, hot isostatic pressing and injection molding. As China’s TOP3 advanced ceramics manufacturer, Mingrui Ceramics’ main forming processes are dry pressing and cold isostatic pressing. This article will introduce the cold isostatic pressing process.

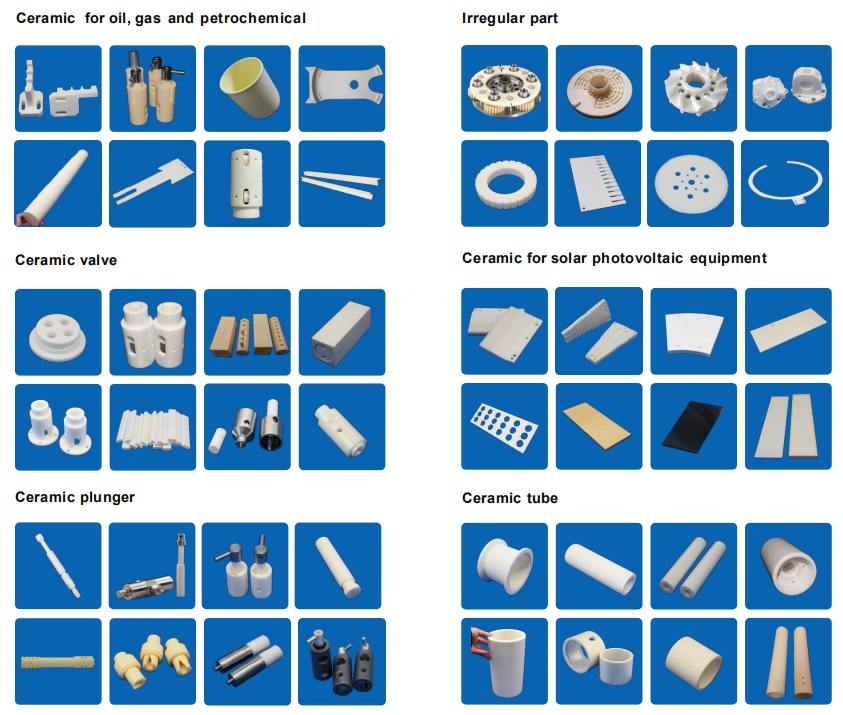

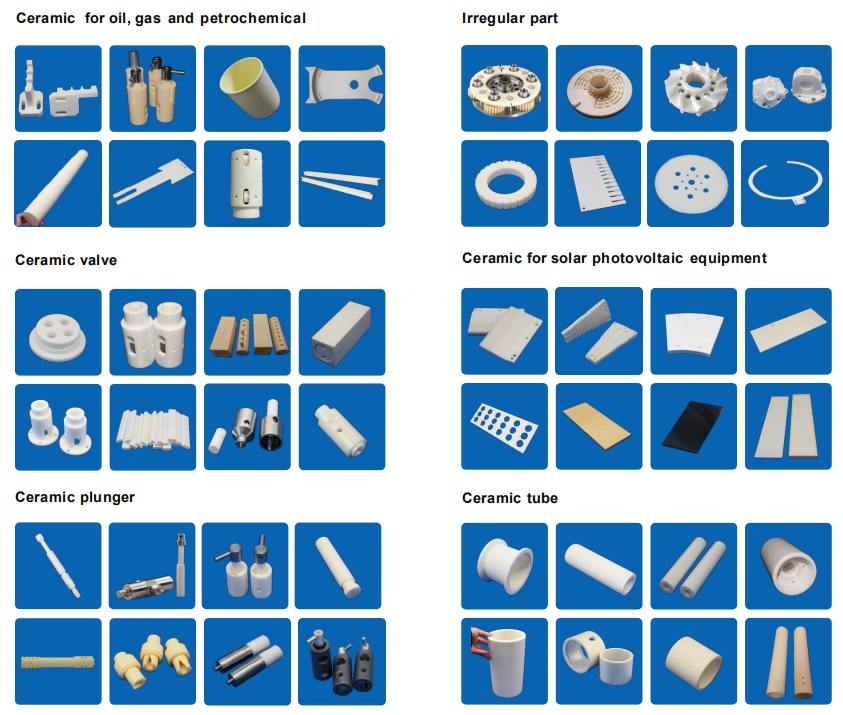

Alumina and zirconia ceramic structural parts formed by cold isostatic pressing of Mingrui Ceramics

Cold isostatic pressing is a powder metallurgy processing method that uses high pressure to press powder materials into compact bodies. Its advantages and features include:

High density: cold isostatic pressing can make the powder material form a dense green body under high pressure, which has a high density, usually reaching more than 95% of the theoretical density.

Fine grains: In the process of cold isostatic pressing, due to plastic deformation and recrystallization under high pressure, a body with fine grains can be obtained, thereby improving the strength and toughness of the material.

Complex shapes: By adopting different mold structures and process parameters, cold isostatic pressing can produce blanks of various complex shapes to meet the needs of different application fields.

Low material loss: There is no melting during cold isostatic pressing, so there is no chemical reaction and gas phase consumption, and there is almost no material loss.

High production efficiency: cold isostatic pressing is easy to operate, the process is stable, and can be mass-produced, so the production efficiency is high.

Strong controllability: The process parameters of cold isostatic pressing can be precisely controlled, such as pressure, temperature, holding time, etc., so that a green body with specific properties and microstructure can be obtained.

Based on the above advantages and characteristics, cold isostatic pressing is widely used in the preparation of blanks of materials with high strength, high toughness, high electrical conductivity, and high thermal conductivity, such as cermet composite materials, alumina ceramics, and silicon carbide ceramics.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730