Silicon nitride ceramics are used in aerospace military industry, mechanical engineering, communication, electronics, automobile, energy, chemical biology and other fields because of their high temperature resistance, corrosion resistance, wear resistance and unique electrical properties.

Especially in the field of high-temperature structural ceramics, silicon nitride ceramics are new materials with the best comprehensive performance, the most application potential and the hope to replace nickel-based alloys and to be widely used in high-temperature fields.

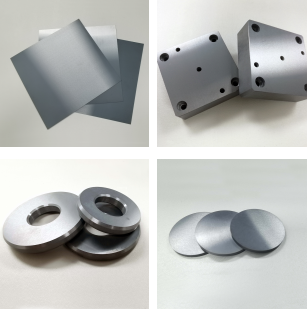

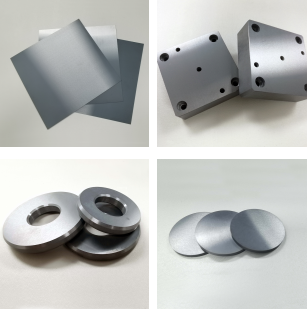

Silicon nitride ceramic structural parts

1. Basic properties of silicon nitride

The detailed performance indicators of silicon nitride are as follows:

1.1. Heat resistance. Under normal pressure, Si3N4 has no melting point and can be directly decomposed at about 1870°C. It can resist oxidation to 1400°C, and the actual use can reach 1200°C (the mechanical strength will decrease if it exceeds 1200°C).

1.2. Small thermal expansion coefficient (2.8-3.2)×10-6/℃, high thermal conductivity, thermal shock resistance, no cracking from room temperature to 1000℃ thermal shock.

1.3. The friction coefficient is small (0.1), and it has self-lubricating properties (the friction coefficient of the metal surface with oil is 0.1-0.2).

1.4. Stable chemical properties, corrosion resistance, does not react with other inorganic acids except hydrofluoric acid, does not react with oxygen in a dry atmosphere of 800°C, and when the temperature exceeds 800°C, a silicon oxide film begins to form on the surface, as the temperature rises The high silicon oxide film gradually becomes stable, and a dense silicon oxide film can be formed with oxygen at about 1000 °C. It can be kept basically stable up to 1400°C.

1.5. Silicon nitride has high hardness, wear resistance, Mohs hardness is second only to diamond, cubic boron nitride, boron carbide, silicon carbide, and is resistant to mechanical shock.

1.6. Silicon nitride is a covalent bond compound, which is difficult to densify. Sometimes it needs to add additives. The density is about 3.4 (the density of different molding methods is different, the density of hot pressing is higher, the density of steel is about 7.85, and the density of titanium is about 7.85. The density of the alloy is about 4.5, and the unit is g/cm3).

1.7. High brittleness, which is a common problem of most ceramic materials, can be toughened by continuous fiber to increase its toughness.

2. The application of silicon nitride ceramics in the field of aerospace and military industry:

Aviation manufacturing is the most concentrated high-tech field in the manufacturing industry. It belongs to advanced manufacturing technology and is a leader in new materials, new processes and new technologies. Taking the turbine engine of an aircraft as an example, the application of silicon nitride in aviation manufacturing is explained.

aircraft turbine engine

Taking the turbojet engine of an aircraft as an example, the temperature of compressor components is below 650°C, and currently titanium alloys, aluminum alloys and heat-resistant steels are mainly used. The temperature in the combustion zone of the combustion chamber is as high as 1800-2000°C. After the air flow is introduced to cool, the wall temperature of the combustion chamber is still above 900°C. It is usually made of high-temperature alloy (nickel-based and cobalt-based alloy) plates to prevent gas erosion, thermal corrosion and heat insulation. , Often spray protective layer, now using dispersion strengthened alloy without coating can prepare a combustion chamber resistant to 1200 ℃.

Mechanism ceramic silicon nitride is heat-resistant and can still have high strength and stiffness at 1400°C (but the mechanical strength will decrease when it exceeds 1200°C), but it is relatively brittle. Reinforced ceramics reinforced with continuous fibers can be applied to turbine components, especially These are the small engine's

ceramic blades, turbine outer ring and air bearings. In addition, silicon nitride ceramics have a low specific density, which is only 41% of that of steel bearings, which can effectively reduce the weight of aircraft engines and reduce fuel consumption.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730