Yttria-Stabilized Zirconia (YSZ) is a material that improves the crystal structure and stability of zirconia by doping with stabilizer yttrium oxide (Y2O3). The following is a detailed introduction to the basic information, advantages, disadvantages and applications of yttrium-stabilized zirconia, telling you why you should choose yttrium-stabilized zirconia.

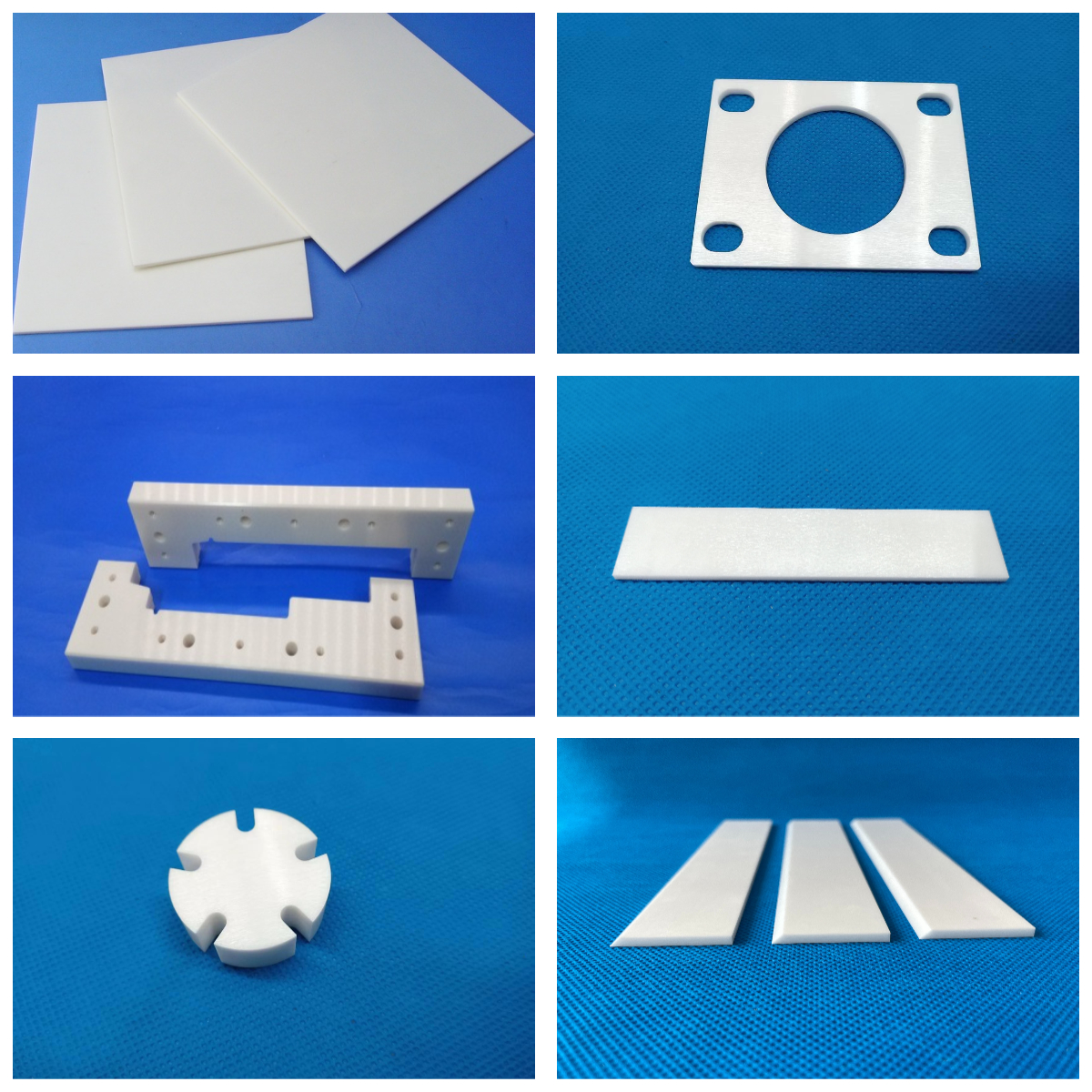

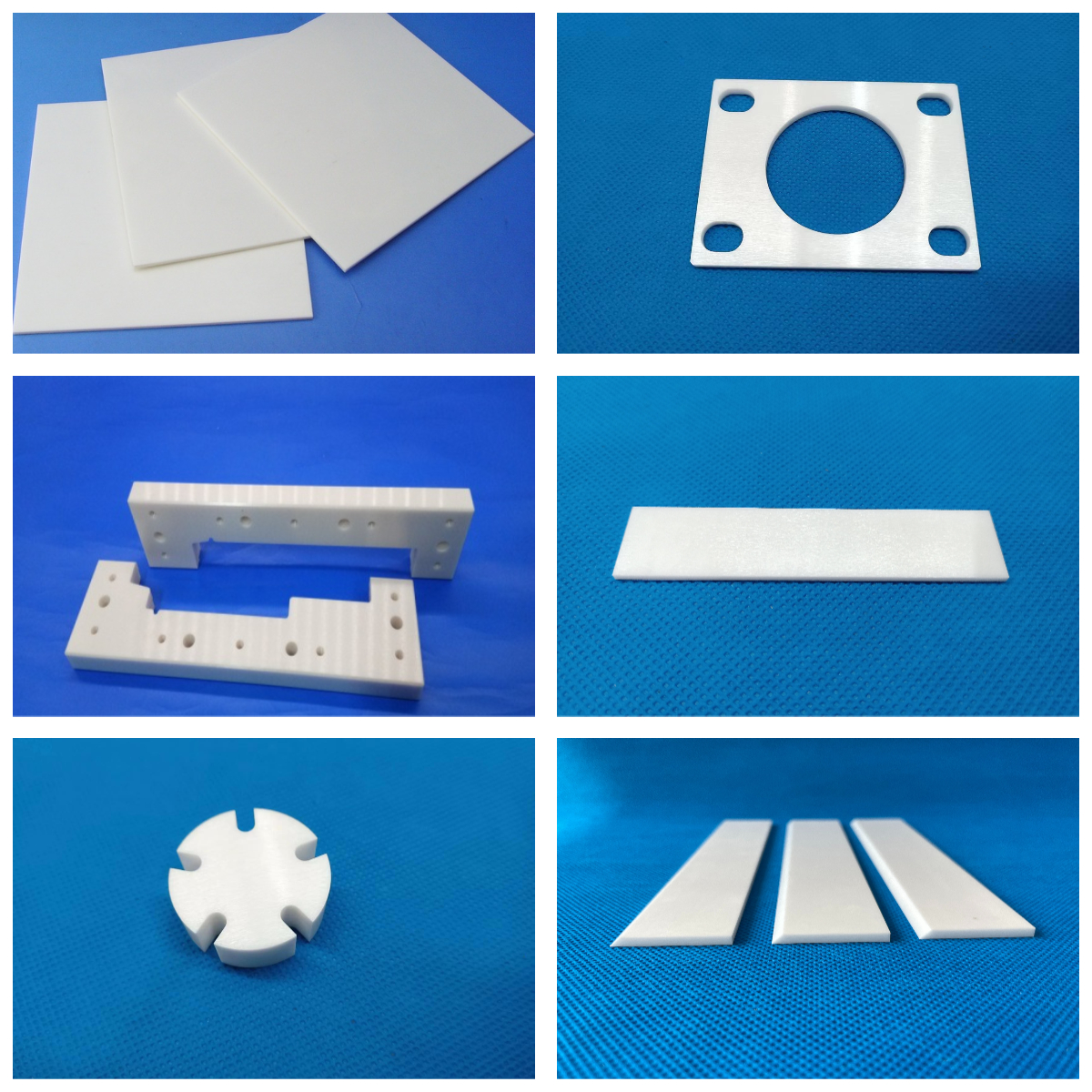

yttrium-stabilized zirconia ceramic plate sheet produced by Mingrui Ceramic

1. Basic properties of yttrium-stabilized zirconia

Ionic conductivity: At high temperatures (600~1000℃), yttrium-stabilized zirconia has good ionic conductivity.

Microparticle structure: Its primary particle diameter is 200~400 angstroms (length units) of uniform microparticles, and it has good sintering properties.

Thermal stability: When sintered at 1500~1500℃, it can form a sintered body with high strength and high toughness.

2. Advantages of yttrium-stabilized zirconia

High temperature stability: Yttrium-stabilized zirconia has good ionic conductivity at high temperatures (600~1000℃), which makes it an ideal choice for high-temperature applications.

Its operating temperature can exceed 1800℃, which is suitable for ultra-high temperature environments, such as making crucibles for vacuum induction melting, ultra-high temperature electric furnace heating elements for high-temperature furnaces, etc.

Excellent physical properties: It has the characteristics of high strength, high toughness, high density and good wear resistance. It is suitable for making high-strength, high-toughness and wear-resistant products, such as mill liners, cutting tools, etc.

The thermal expansion coefficient is close to that of steel, which is conducive to maintaining dimensional stability at high temperatures.

Good chemical stability: It has good corrosion resistance to a variety of acid and alkali solutions and corrosive media, and can be used in acidic or alkaline media.

Outstanding material compositeness: After compounding with other materials (such as Al2O3, SiO2), it can significantly improve the performance parameters of the material, such as fracture toughness, bending strength, etc.

3. Disadvantages of yttrium-stabilized zirconia

Thermal stability limitation: Although yttrium-stabilized zirconia performs well at high temperatures, its performance may be affected to a certain extent under extremely high temperature conditions.

Mechanical strength problem: In some specific applications, the mechanical strength of yttrium-stabilized zirconia may not be sufficient to meet the requirements, and it needs to be compounded with other materials or enhanced by special processes.

Complex preparation process: There are various preparation methods for yttrium-stabilized zirconia, but each method has its unique advantages and disadvantages and process requirements. For example, although the sol-gel method is easy to prepare high-purity products, the production cost is high and the particle forming process is difficult to control.

Cost factors: Due to its excellent performance and wide application fields, the manufacturing cost of yttrium-stabilized zirconia is relatively high, which may limit its use in some cost-sensitive applications.

4. Application fields of yttrium-stabilized zirconia

High-strength, high-toughness wear-resistant products: such as mill liners, cutting tools, wire drawing dies, hot extrusion dies, tubes, nozzles, valves, balls, pump parts, various sliding parts, etc.

Functional ceramics and structural ceramics: including electronic ceramics, bioceramics, etc.

High-temperature furnace equipment: used to make crucibles for vacuum induction melting, ultra-high temperature electric furnace heating elements for high-temperature furnaces, high-temperature furnace tubes, etc.

Temperature measuring elements: made into high-temperature solution continuous temperature measurement zirconia elements and various oxygen meters.

Refractory materials: such as electronic ceramic sintering support pads, refractory materials for melting glass and metallurgical metals.

Other fields: It is also widely used in catalysts, electronic materials, medical devices and other fields, such as high-precision polishing, ball milling and particle dispersion, carriers for catalytic reactions, artificial joints and dental implants.

5. Preparation method of yttrium-stabilized zirconia

There are various methods for preparing yttrium-stabilized zirconia, including coprecipitation, sol-gel, coprecipitation-gel, alcohol-water solution, hydrothermal, microemulsion, high-energy ball milling, self-propagating method, etc. Each method has its own advantages and disadvantages. For example, the hydrothermal method does not require high-temperature calcination and ball milling, but the particles are not easy to disperse; the coprecipitation method has high product purity and low production cost, but it is easy to introduce impurities and the reaction process is long; the sol-gel method has a low reaction temperature and is easy to prepare high-purity products, but the production cost is high and the particle formation process is difficult to control.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730