Ceramic washers and ceramic gaskets are a kind of sealing elements widely used in many fields. They are mainly made of ceramic materials and have the characteristics of high temperature resistance, corrosion resistance, good insulation and high hardness. The following is a detailed introduction to ceramic washers:

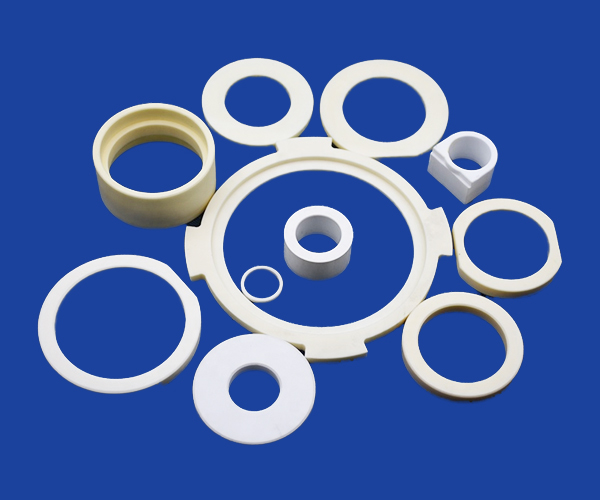

Alumina and zirconia ceramic washers and gaskets produced by Mingrui Ceramics

1. Main features of ceramic washers

· High temperature resistance: Ceramic washers and ceramic gaskets can maintain stable performance in high temperature environments and are not easy to deform or melt.

· Corrosion resistance: They have excellent corrosion resistance to a variety of chemical substances and are suitable for use in harsh environments.

· Good insulation: Ceramics are excellent insulating materials, so ceramic washers and ceramic gaskets can play an important role in electrical applications.

· High hardness: The high hardness of ceramic materials makes ceramic washers have high wear resistance and pressure resistance.

2. Application fields of ceramic washers

Ceramic washers and ceramic gaskets are widely used in many fields such as construction, electrical appliances, automobiles, sealing, chemicals, boilers, engineering, etc. In the construction field, ceramic gaskets can be used to seal high-temperature pipes; in the electrical field, ceramic gaskets are often used for packaging and fixing electronic components due to their insulation properties; in the automotive field, ceramic gaskets can be used to seal high-temperature components such as engines.

3. Types and specifications of ceramic gaskets

There are many types of ceramic gaskets, including alumina ceramic gaskets, zirconia ceramic gaskets, silicon nitride ceramic gaskets, etc. Different types of ceramic gaskets have different properties and uses. At the same time, the specifications of ceramic gaskets are also varied, including different sizes, shapes and thicknesses to meet the needs of different applications.

4. Recommendations for the selection of ceramic gaskets

When selecting ceramic gaskets and ceramic gaskets, the appropriate material, specifications and performance should be determined according to the specific application and needs. At the same time, factors such as the supplier's reputation, product quality and after-sales service also need to be considered. It is recommended to cooperate with suppliers with rich production experience and good market reputation. Mingrui Ceramics has a production department of nearly 500 people and experienced engineers. It is a top 3 advanced ceramic manufacturer in China and has become a ceramic supplier for many Fortune 500 companies and listed companies.

In summary, ceramic gaskets and ceramic gaskets are a kind of sealing components with excellent performance and are widely used in many fields. When selecting and using them, it is necessary to fully understand their characteristics and requirements to ensure that they can play the best performance and effect.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730