Ceramic gears are gears made of advanced ceramic materials with unique physical and chemical properties, which make them widely used in many fields. The most widely used alumina and zirconia ceramic gears in advanced ceramic materials are important components in modern industry and have unique performance and application advantages. The following is a detailed comparative analysis of the two ceramic gears:

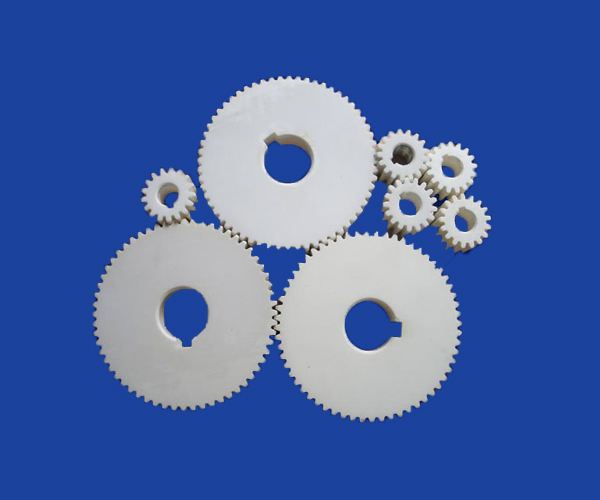

Some ceramic gears produced by Mingrui Ceramics

1. Alumina ceramic gears

Material properties

Wear resistance: Alumina ceramics have high hardness, so the gears made have excellent wear resistance.

High temperature resistance: Alumina ceramics can maintain stable performance in high temperature environments and are not easy to deform or damage.

Corrosion resistance: It has excellent corrosion resistance to a variety of chemical substances and is suitable for corrosive environments.

Application fields

Alumina ceramic gears are widely used in mechanical equipment, industrial equipment and other fields, especially in places where high wear resistance, high temperature resistance and corrosion resistance are required.

In food machinery, textile machinery and other industries, alumina ceramic gears are favored for their non-toxic and corrosion-resistant properties.

Development trend

With the advancement of technology, alumina ceramic gears are developing in the direction of heavy load, high speed, high precision and high efficiency.

The research and development of new tooth shapes and manufacturing technologies will further improve the load-bearing capacity and service life of alumina ceramic gears.

2. Zirconia ceramic gears

Material properties

High strength: Zirconia ceramics have extremely high strength, so that the gears made of it can withstand greater loads.

Good toughness: Compared with other ceramic materials, zirconia ceramics have better toughness and are not easy to break.

Wear resistance: It also has high wear resistance and is suitable for long-term high-load operation.

Application fields

Zirconium oxide ceramic gears are widely used in aerospace, automobile manufacturing, precision instruments and other fields, especially in places where material performance requirements are extremely high.

Zirconia ceramic gears can maintain stable performance in harsh environments such as high temperature, high pressure, and high corrosion.

Development trend

With the advancement of materials science, the manufacturing process and performance of zirconia ceramic gears will continue to improve.

The research and development of new zirconia ceramic materials will promote its application in more fields.

3. Comparison of alumina and zirconia ceramic gears

|

|

Alumina Ceramic Gears |

Zirconium Oxide Ceramic Gears |

|

Material properties |

High hardness, high temperature resistance, corrosion resistance |

High strength, good toughness, wear resistance |

|

Application fields |

Mechanical equipment, industrial equipment, food machinery, textile machinery, etc. |

Aerospace, automobile manufacturing, precision instruments, etc. |

|

Development trend |

Heavy load, high speed, high precision, high efficiency |

Manufacturing process and performance are constantly improving, new material research and development |

In summary, alumina and zirconia ceramic gears have their own characteristics and play an important role in different application fields. With the advancement of science and technology and the improvement of manufacturing processes, the performance and application range of these two ceramic gears will continue to expand.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730