Alumina ceramic discs are an industrial material with many excellent properties and are widely used in many fields. The following is a detailed analysis of alumina ceramic discs:

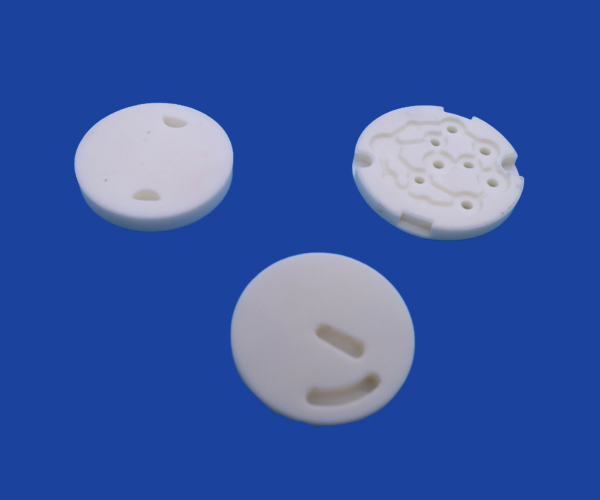

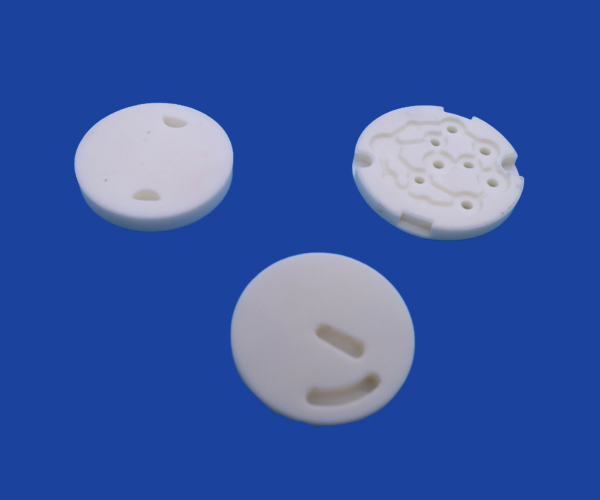

Precision Machined Zirconia Ceramic Discs

1. Physical and chemical properties of alumina ceramic discs

High purity and density: The alumina content of alumina ceramic discs is usually as high as 95% or even more than 99%, and the density reaches 3.6 g/cm3, showing its high material density.

Hardness and wear resistance: Its Rockwell hardness exceeds 80 HRA, the compressive strength is as high as 850 MPa, the bending strength exceeds 290 MPa, and the fracture toughness KIC value reaches 4.8 MPa·m square root. These excellent physical properties make alumina ceramic discs have excellent wear resistance.

Insulation: Alumina ceramics are an excellent electrical insulator with a low dielectric constant, suitable for insulation needs in power, electronic devices and other fields.

Corrosion resistance: It has high chemical stability and can withstand the erosion of corrosive media such as acids and alkalis. It is suitable for corrosive working conditions in the fields of chemical industry, environmental protection, etc.

Thermal conductivity: The thermal conductivity coefficient is 20 watts/meter Kelvin, which shows its good thermal conductivity and is suitable for heat dissipation and heat transfer components of high-temperature equipment.

2. Manufacturing process of alumina ceramic discs

The manufacturing process of alumina ceramic discs usually includes the following steps:

Raw material preparation: Select high-quality high-purity alumina powder as the main raw material, and add a certain proportion of additives and stabilizers to ensure the purity and stability of the material.

Molding: After the mixed raw materials are stirred and ground, they are pressed or injected into a ceramic disc of a specific shape and size.

Sintering: The formed ceramic disc is placed in a high-temperature furnace for sintering. Through chemical reactions and crystal growth at high temperatures, the ceramic material obtains higher density and excellent performance.

Surface treatment: Through grinding, polishing and other processes, the surface of the ceramic disc is made smooth and flat, improving its aesthetics and processing performance.

3. Application fields of alumina ceramic discs

Due to the above-mentioned excellent properties, alumina ceramic discs are widely used in the following fields:

Industrial fields: such as mining, metallurgy, mechanical processing and other industries, used for particle classification, crushing and dispersion in the production of abrasives and coating materials.

Electricity and electronics: as insulating partition elements, insulating gaskets of electrical equipment, etc., to ensure the stable operation of power and electronic equipment.

Chemical and environmental protection: used for equipment parts under corrosive conditions such as chemical reactors and pipeline linings to ensure the long-term use of chemical and environmental protection equipment.

Other fields: such as the fixed ring of the lithography machine in the semiconductor industry and the ceramic heating element of the beauty instrument, the high precision and stability of alumina ceramic discs are also required.

In summary, alumina ceramic discs are a material with excellent functions and a wide range of applications. Its wear resistance, insulation, corrosion resistance, thermal conductivity and mechanical strength make it play an important role in various industries. With the continuous development of technology, the research and application of alumina ceramic discs will continue to deepen, providing more possibilities and opportunities for various industries.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 0769-85090316-8038

Phone: +86 0769-85090316-8038 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: admin@cerampart.com

Skype: admin@cerampart.com Wechat: +86 18122974730

Wechat: +86 18122974730