Ceramic gear higher hardness machinery alumina zirconia precision ceramic gears

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Custom according to the drawings

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

- Customized:Can be custom for special sizes and shapes

1. Factory price and shipment within 24 hours In stocks

2. MOQ:1qty

3. Payment Term: PayPal; T/T; L/C etc.

4. Shipment: by sea by air by courier by post etc.

High-purity alumina ceramic gears High-hardness, high-temperature and wear-resistant zirconia ceramic gears

Ceramic gears and ceramic structural parts produced by Mingrui Ceramics

Ceramic gears and ceramic structural parts produced by Mingrui Ceramics

Performance advantages of alumina ceramic gears:

· Wear resistance: Alumina ceramics have high hardness, so the gears made have excellent wear resistance.

· High temperature resistance: Alumina ceramics can maintain stable performance in high temperature environments and are not easy to deform or damage.

· Corrosion resistance: It has excellent corrosion resistance to a variety of chemicals and is suitable for corrosive environments.

Performance advantages of zirconia ceramic gears:

· High strength: Zirconia ceramics have extremely high strength, so that the gears made of it can withstand greater loads.

· Good toughness: Compared with other ceramic materials, zirconia ceramics have better toughness and are not easy to break.

· Wear resistance: It also has high wear resistance and is suitable for long-term high-load operation.

Application fields of alumina and zirconia ceramic gears

Alumina ceramic gears are widely used in mechanical equipment, industrial equipment and other fields, especially in places where high wear resistance, high temperature resistance and corrosion resistance are required.

In industries such as food machinery and textile machinery, alumina ceramic gears are favored for their non-toxic and corrosion-resistant properties.

Zirconia ceramic gears are widely used in aerospace, automobile manufacturing, precision instruments and other fields, especially in occasions where material performance requirements are extremely high.

Zirconia ceramic gears can maintain stable performance in harsh environments such as high temperature, high pressure and high corrosion.

Ceramic Parts and components manufacturer,OEM

High Quality, High Precision, Delivery on time, Factory Price

A gear is a mechanical element on the rim of which a gear is continuously engaged to transmit motion and power.

As a the manufacturer of ceramic gears, us offer a wide the type or sizes of the ceramic gears for industry machinable and ceramic parts applications.our ceramic gears are made of Zirconia, Alumina, Silicon and other advanced ceramics. In stocks and offer customization.

- High Temperature Ability

- Abrasion Resistant

- Wear Resistance

- Chemical Resistance

- Electrical Insulator

- Corrosion resistant

- High compressive strength

- High mechanical Strength

- Resists strong acid and alkali attack at high temperatures

- Excellent electrical insulation properties

- Decent thermal conductivity

Some part of us machinable cases specifications:

|

INTERNAL GEARS AND INTERNAL SPLINES |

|

|

MILLING |

SHAPING |

TOOTH GRINDING |

|

Maximum O.D. |

2500 mm |

2500 mm |

2500 mm |

|

Minimum I.D. |

650 mm |

50 mm |

100 mm |

|

Maximum Face Width |

500 mm |

500 mm |

500 mm |

|

Maximum Diametral Pitch |

DP 1 |

DP 1 |

DP 0.5 |

|

Maximum Module |

26 mm |

26 mm |

45 mm |

|

AGMA Level/ DIN Level |

DIN Class 8 |

DIN Class 8 |

DIN Class 4 |

|

Tooth Surface Finishing |

Ra 3.2 |

Ra 3.2 |

Ra 0.6 |

|

Maximum Helix Angle |

±22.5° |

±22.5° |

±45° |

|

EXTERNAL GEARS AND EXTERNAL SPLINES |

|

|

HOBBING |

MILLING |

TOOTH GRINDING |

|

Maximum O.D. |

1250 mm |

2500 mm |

2500 mm |

|

Minimum O.D. |

20 mm |

200 mm |

20 mm |

|

Maximum Face Width |

500 mm |

500 mm |

1480 mm |

|

Maximum Diametral Pitch |

DP 1 |

DP 1 |

DP 0.5 |

|

Maximum Module |

26 mm |

26 mm |

45 mm |

|

AGMA Level/ DIN Level |

DIN Class 8 |

DIN Class 8 |

DIN Class 4 |

|

Tooth Surface Finishing |

Ra 3.2 |

Ra 3.2 |

Ra 0.6 |

|

Maximum Helix Angle |

±45° |

±45° |

±45° |

Tips: As a professional manufacturer of ceramic structural parts, we provide customized services to customers.OEM

Tips: As a professional manufacturer of ceramic structural parts, we provide customized services to customers.OEM

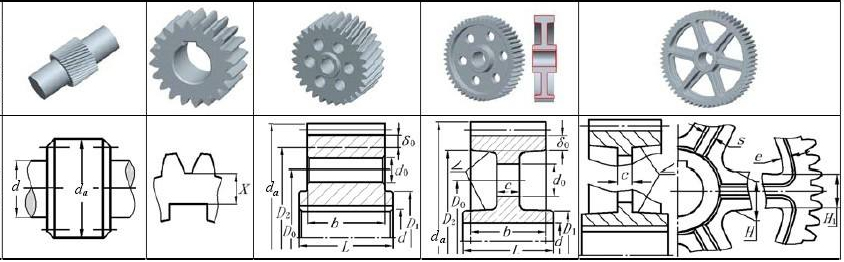

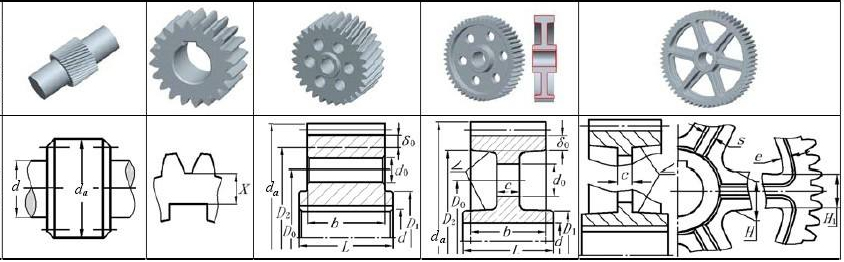

Structure classification of Ceramic Gear

Generally, there are wheel teeth, tooth groove, end face, normal face, tooth top circle, tooth root circle, base circle, indexing circle.

Classification by wheel shaft relative position

Plane gear drive, straight cylindrical gear drive, external gear drive, internal gear drive, rack drive, helical gear drive, herringbone gear drive, space gear drive, conical gear drive, staggered helical gear drive, worm gear drive

By process

Conical gear, blank gear, spiral gear, internal gear, straight gear, worm gear

Gear modulus selection

Module of gear

Preferred module:

0.1mm、0.12mm、0.15mm、0.2mm、0.25mm、0.3mm、0.4mm、0.5mm、0.6mm、0.8mm、1mm、1.25mm、1.5mm、2mm、2.5mm、3mm、4mm、5mm、6mm、8mm、10mm、12mm、 14mm、16mm、20mm、25mm、32mm、40mm、50mm;

Optional module:

1.75mm、2.25mm、2.75mm、3.5mm、4.5mm、5.5mm、7mm、9mm、14mm、18mm、 22mm、28mm、36mm、45mm;

Rarely used module:

3.25mm、3.75mm、6.5mm、11mm、30mm;

Ceramic pump material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2) etc

|

|

Ceramic gear precision process:

|

Precision of manufacture |

|

Dimensional accuracy |

Up to 0.001mm |

|

Smoothness |

Highest possible mirror |

|

Concentricity |

Up to 0.003mm |

|

Parallelism |

Up to 0.002mm |

|

The inner hole tolerance |

The minimum 0.005mm |

|

Straight flute |

The narrowest 0.1x100mm |

|

The thickness of the size |

Minimum to 0.02mm |

|

The screw thread |

Minimum internal thread M2 |

|

Cylindricity |

Up to 0.004mm |

|

The linear tolerance |

Up to 0.001mm |

|

The smallest aperture |

The minimum 0.07mm |

|

Precision process |

CNC maching,grinding,lapping |

|

Surface finish |

Glazed,polishing or metallized |

Visual quality:

1. No cracks, no dark dots, no contamination and sharp edges;

2. Evenly distributed glaze with very smooth surface |

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

|

|

Ceramic Parameter:

|

Properties |

Units |

AL2O3 |

ZrO2 |

SiC |

Si3N4 |

|

Density |

g/cm3 |

3.65-3.93 |

5.95-6.0 |

3.12 |

3.23 |

|

Water absorption |

0 |

0 |

0 |

0 |

0 |

|

Coefficientof thermal expansion |

10-16/k |

7.9-8.5 |

10.5 |

3 |

3.2 |

|

Modulus of elasticity young`s mod |

GPa |

280-340 |

210 |

440 |

300 |

|

Poission`s ratio |

/ |

0.21-0.22 |

0.3 |

0.17 |

0.26 |

|

HV hardness hv |

MPa |

1650 |

1300-1365 |

2800 |

1500 |

|

Flexural strength |

MPa |

310 |

950 |

390 |

720 |

|

Flexural strength(700℃) |

MPa |

230 |

210 |

380 |

450 |

|

Compressive strength |

MPa |

2200 |

2000 |

1800 |

2300 |

|

Fracture toughness |

MPa*m1/2 |

4.2 |

10 |

3.9 |

6.2 |

|

Heat conductivity |

W/m*k |

26-30 |

2-2.2 |

120 |

25 |

|

Electrical resistivity |

Ω*mm2/m |

>1016 |

>1015 |

>103 |

>1013 |

|

Max use temperature |

℃ |

1750 |

1050 |

1550 |

1050 |

|

Resistance to acid alkaline |

/ |

high |

high |

high |

high |

|

Dielectric constant |

/ |

9.6 |

29 |

9.66-10.03 |

/ |

|

Dielectric strength |

KV/mm |

8.7 |

9 |

/ |

/ |

|

Thermal shock resistance |

△T(℃) |

180-220 |

280-350 |

230-260 |

/ |

|

Tensile strength |

MPa |

248 |

250 |

/ |

/ |

|

Customization & Machining Service:

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic gears or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

|

For more information about ceramics parts,please contact our engineers in time >>> |

|

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730