High-purity alumina ceramics have low high-frequency dielectric loss and excellent insulation properties, making them suitable for the preparation of insulating devices, ceramic substrates, and transparent alumina ceramics. Among these, ceramic substrates and transparent alumina ceramics are widely used in many special optical instruments, lighting equipment, and space satellite equipment.

In terms of ceramic substrates,

alumina ceramic substrates are the most widely used substrate material in the contemporary electronic information industry and are the basic material for integrated circuit chips. For example, in the LED lighting field, the thermal expansion coefficient of mainstream substrates is 14~17×10⁻⁶/K. Under large temperature differences and rapid temperature changes, the PCB expands more drastically than the chip package, leading to desoldering problems. In this context, the thermal expansion coefficient of alumina ceramic substrates is closer to that of the chip, effectively avoiding such problems.

Regarding transparent alumina ceramics, since Dr. Coble first developed and prepared transparent alumina ceramics (also known as transparent polycrystalline alumina ceramics) in 1959, the research and application of transparent alumina ceramics have received widespread attention. Compared with glass, transparent alumina ceramics have higher strength, hardness, and toughness, and their excellent surface wear resistance is unmatched by glass; compared with single-crystal materials, transparent alumina ceramics have lower preparation temperatures and shorter production cycles. It is precisely because of these properties that transparent alumina ceramics have become a research hotspot, finding extremely wide applications in optics, the preparation of special instruments, lighting, electronic technology, high-temperature technology, national defense and military, and aerospace fields. For example, utilizing the light transmittance, corrosion resistance, and high-temperature stability of transparent alumina ceramics, they can be made into luminous arc tubes for use in high-pressure sodium lamps.

Medical Applications

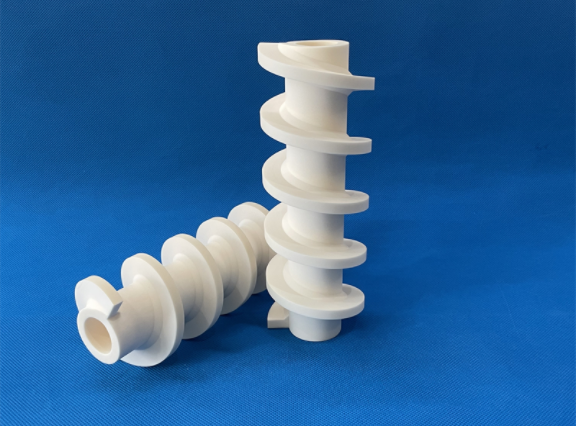

Biomedical materials can repair human body functions without causing adverse effects. Medical and health organizations have very strict requirements for biomedical materials. These materials must not only be biocompatible but also non-toxic, environmentally friendly, and durable. High-purity alumina ceramics, due to their excellent biocompatibility, mechanical properties, and chemical stability, do not cause rejection reactions when implanted in the human body. They are widely used in the preparation of artificial bones, screws, and artificial joints, and have been recognized in clinical and research applications.

The special properties and applications of high-purity alumina ceramics, which distinguish them from conventional alumina ceramics, are mainly attributed to their high purity, as well as strict requirements for particle size and dispersion. This places significant demands on the preparation of high-purity alumina powders. Of course, the processing methods also have a significant impact on the performance and applications of high-purity alumina ceramics. As a result, some so-called high-purity alumina ceramics produced by small workshops on the market may show quality issues during inspection. Choosing a qualified, large-scale manufacturer that can provide certification helps avoid many potential problems.

With years of experience in the industrial ceramics industry, Mingrui Ceramic offers 95–99.99% alumina ceramic component solutions. If you have requirements for

high-purity alumina ceramic parts, please feel free to contact us for further discussion.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730