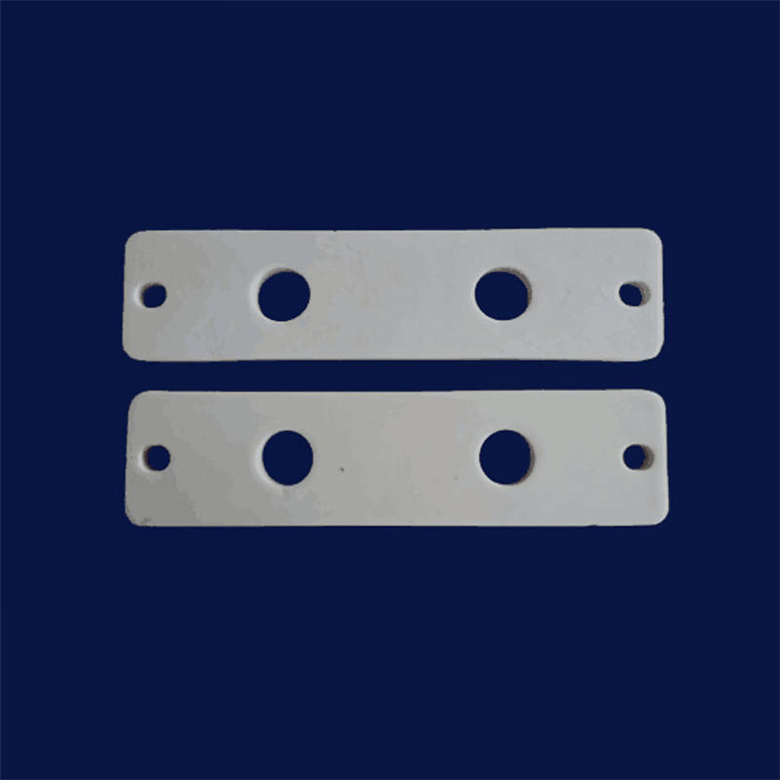

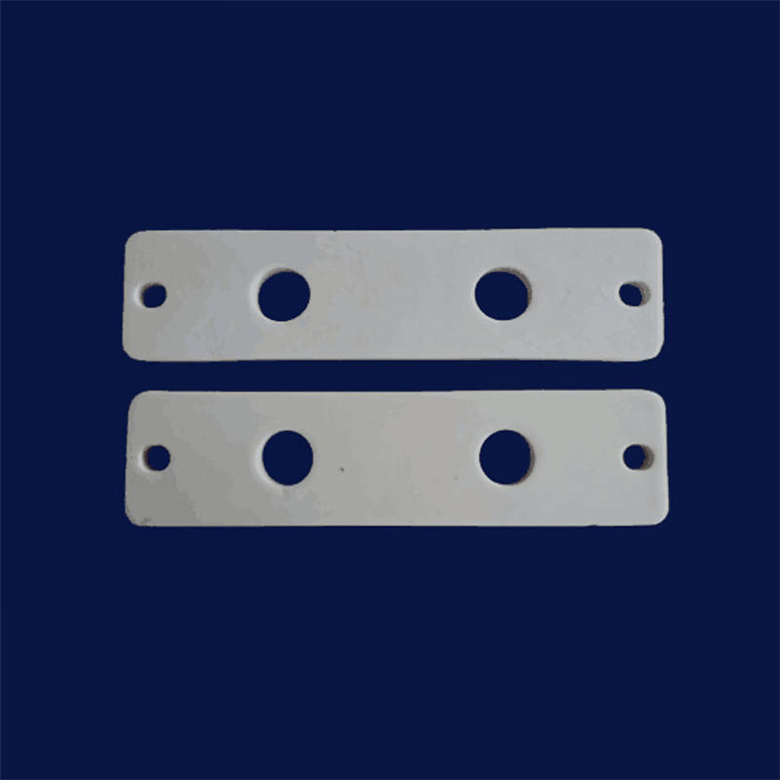

Zirconia ceramic plate through powder forming for wool embryo, and then through ceramic processing is ceramic plate to meet customer requirements, so what processing requirements must be met in the processing?Mingrui ceramics factory gives everybody analysis below.

Zirconia ceramics are widely used for their high melting and boiling points, high hardness, insulation at room temperature and conductivity at high temperature.

Zirconia ceramics are widely used for their high melting and boiling points, high hardness, insulation at room temperature and conductivity at high temperature.

一、Shape grinding: this step depends on the processing procedure selected.

1. Pay attention to the distance the needle travels per unit time, and do not move too fast.

2. Timely change the needle.

二, the thickness of the working bracket:

the thickness of the bracket before sintering is at least 0.7mm. It is not less than 0.4mm after sintering.

三、sintering:

Before sintering, the debris produced during grinding on the top of the bracket should be cleaned clean. After sintering, the size of the bracket will shrink by 25%.

Therefore, it is necessary to use a matching sintering furnace (temperature up to 1600 ℃). Four, open furnace: 300 ℃ It is important to note that there should be enough sintering work space during processing to prevent deformation. If necessary (relatively large bridge) to sintering the whole, sintering in the cut off each pivot. After sintering, this material can achieve the required physical properties, such as the maximum strength approximate to 1200MPa. Zirconia material strength is high, if a fracture is found, it is basically turning when the problem occurs.

Mingrui Ceramics Technology Co., Ltd. is a research and development, production and sales, for modern industry, energy, agriculture, transportation, communications, construction, military fields to provide new materials of high-tech enterprises. Specializing in the production of zirconia (yttrium stabilized/Magnesium STABILIZED/cerium stabilized), alumina (95/97/99/99.5/99.7/99.8/99.9/99.99) ceramic products.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730