In the wave of industrial equipment upgrades, the limitations of single-material performance are becoming increasingly apparent. Stainless steel possesses toughness, impact resistance, and structural stability, but it is prone to wear and tear in scenarios requiring resistance to strong corrosion. Ceramics, while possessing high hardness, chemical inertness, and high-temperature resistance, suffer from brittleness and the inability to bear structural loads independently. How can we combine metals and ceramics to address the pain points of diverse industrial operating conditions and achieve 1+1>2?

Introduction to Various Ceramic-to-Metal Components Manufacturing Processes

In the field of precision manufacturing, the choice of process directly determines product performance. A variety of ceramic-metal combination processes cover a wide range of application scenarios, from electronic components to industrial equipment. For high-end electronics and aerospace applications requiring extremely high connection strength and sealing, brazing technology can be used. Through the strong affinity between the active element titanium and ceramics, a high-strength metallurgical connection between the two is achieved. Joints produced using this process combine excellent thermal conductivity with high hermeticity, enabling stable operation in extreme environments and providing reliable support for critical equipment such as power modules in new energy vehicles and vacuum chambers in spacecraft. With high-precision grinding equipment and strict process control, the void rate at the joint interface can be reduced, ensuring the stability of every product.

For industrial pipelines, wear-resistant components, and other applications, thermal spraying and centrifugal casting processes are ideal choices. Thermal spraying uses high temperatures to spray ceramic powder onto the metal surface at high speed, forming a dense coating, allowing metal components to possess both the wear resistance of ceramics and their own structural strength; centrifugal casting uses centrifugal force to tightly bond ceramic particles with a metal binder, suitable for mass production of regularly shaped wear-resistant parts, and widely used in petrochemical, machinery manufacturing, and other fields.

In the customization of precision structural parts, Mingrrui excels at overcoming size limitations through precision inlay and special bonding processes. Ceramic parts are selected after multiple measurements, combined with customized adhesive formulas, maintaining stable performance in different temperature and humidity environments. This successfully achieves the perfect fusion of stainless steel and high-temperature ceramics, creating customized products such as ceramic-metal seats and ceramic pins, adapting to the high-precision needs of industries such as semiconductors and

medical devices.

Mingrui Ceramics has been deeply involved in the field of zirconia and alumina ceramics for many years, providing numerous successful solutions to a wide range of users and becoming a trusted partner of many well-known companies. We also achieve excellence in ceramic-to-metal hybrid components.

Case Study 1

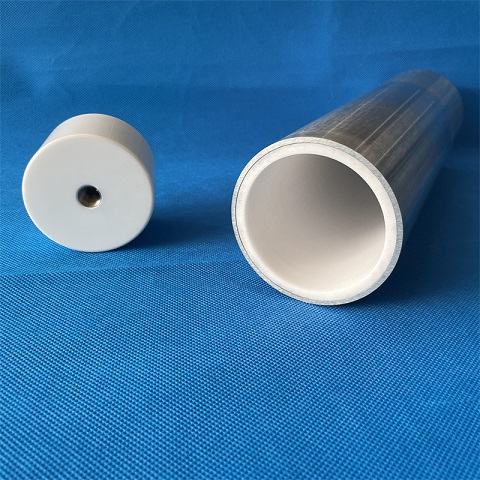

Stainless Steel Lined Ceramic Pipes: Wear-Resistant and Clean Conveying Solutions

As a core component of industrial material conveying, pipelines need to simultaneously address multiple demands: wear resistance, corrosion resistance, and material purity assurance. Stainless steel-lined ceramic pipes, with their scientifically designed composite structure, have become the preferred choice in many industries. This product adopts a composite structure of "stainless steel outer layer + ceramic inner lining." The core relies on a combination of inlay and adhesive bonding processes to achieve tight integration of the two phases. Mingrui employs an interference fit insertion process to precisely embed alumina ceramic linings into pre-machined slots in a stainless steel substrate, supplemented with a special high-temperature adhesive to fill the interface gap. This combination leverages the stainless steel substrate to resist impact loads during material transport and maintain structural integrity, while the ceramic lining provides wear resistance, corrosion resistance, and hygienic properties. This hybrid design effectively overcomes the limitations of single-material solutions: the stainless steel substrate addresses the brittleness and susceptibility to cracking of the ceramic, allowing it to withstand pressure shocks and installation stress under complex operating conditions; the alumina ceramic lining, with a Mohs hardness of 9, offers wear resistance approximately 10 times higher than ordinary carbon steel pipes, suffering virtually no abrasion when handling high-impact materials such as quartz sand or ore powder. Additionally, its chemical stability ensures it does not react with acidic, alkaline, or saline media. The smooth, non-porous surface (coefficient of friction only 0.08–0.12) prevents pipe wall shedding, avoids material sticking, and inhibits bacterial growth. The product’s service life is 5–10 times longer than ordinary pipes, with low flow resistance and 15–20% reduced energy consumption, achieving both durability and cost-effectiveness.

Case Study 2

As a critical device for fluid metering and transfer, plunger pumps demand high wear resistance, tight sealing, and precise dosing accuracy. The metal ceramic plunger pump achieves a significant performance leap through a combination of threaded connections, insertion, and adhesive bonding processes. This product features a stainless steel pump body and connection components, while key metering parts such as the plunger and pump sleeve are made of zirconia ceramic. Multiple processes ensure stable integration: A robust composite structure is achieved through multiple processes: the ceramic plunger and stainless steel drive components are connected with precision threads, combined with surface-hardened metal threaded parts, ensuring both ease of disassembly for maintenance and preventing stress concentration during assembly; the ceramic pump sleeve and stainless steel pump chamber are positioned and fixed through an inlay process, with a corrosion-resistant adhesive sealant at the interface to ensure no leakage under high-pressure conditions. The synergistic advantages of metal and ceramic are fully demonstrated in this product: the stainless steel pump body provides sufficient structural strength and impact resistance, adapting to various industrial installation scenarios; the zirconia ceramic components possess ultra-high hardness and inertness, with a wear resistance life 5-8 times that of chrome-plated steel plungers, extremely low particle release, and do not adsorb materials or undergo chemical reactions, perfectly suited for high-precision conveying needs in pharmaceuticals and chemicals. The metal-ceramic plunger pump achieves a metering accuracy of 0.1%-0.5%, capable of handling non-solid fluid materials with viscosities up to 20000 cps. In the filling of aqueous injections and lyophilized powder injections, it meets GMP hygiene standards and allows for online cleaning and sterilization; in the transportation of highly corrosive chemical media, it can withstand strong acid and alkali corrosion, avoiding the problems of easy corrosion and rapid accuracy degradation of traditional metal plunger pumps, significantly reducing maintenance frequency and downtime losses.

More than just integration, it's about breakthrough.

Mingrui Ceramic has always adhered to the philosophy of “Quality First, Lean and Efficient”, continuously optimizing its ceramic-metal hybrid manufacturing processes. On the materials side, Mingrui ensures product performance from the source, offering a variety of ceramic options—including zirconia, alumina, and silicon carbide—to meet customer requirements. For precision control, leveraging imported grinding equipment and Mitutoyo inspection instruments, Mingrui achieves tolerance control within 5 µm and a surface roughness standard of Ra 0.05, enabling millimeter-level accuracy in the fit between ceramic and metal components. From product design to production and delivery, Mingrui Ceramic provides full-process customized services. Its experienced technical team can design tailored ceramic-metal hybrid solutions based on customer drawings, strictly following ISO quality system standards, ensuring comprehensive control from raw powder to finished product.

Today, Mingrui Ceramic’s products are widely applied in photovoltaic and new energy, aerospace, automotive manufacturing, medical devices, and other industries. The company has established deep partnerships with renowned enterprises such as China Aerospace Corporation, BYD, and Samsung Electronics, empowering industrial upgrades with precision ceramic components.

Whether it's customized precision structural components or mass-produced industrial ceramic parts, Mingrui Ceramics can achieve the optimal integration of ceramics and metals with professional craftsmanship and rigorous quality control. If you have any needs for

ceramic-metal hybrid components, please contact us to explore more possibilities in precision manufacturing!

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730