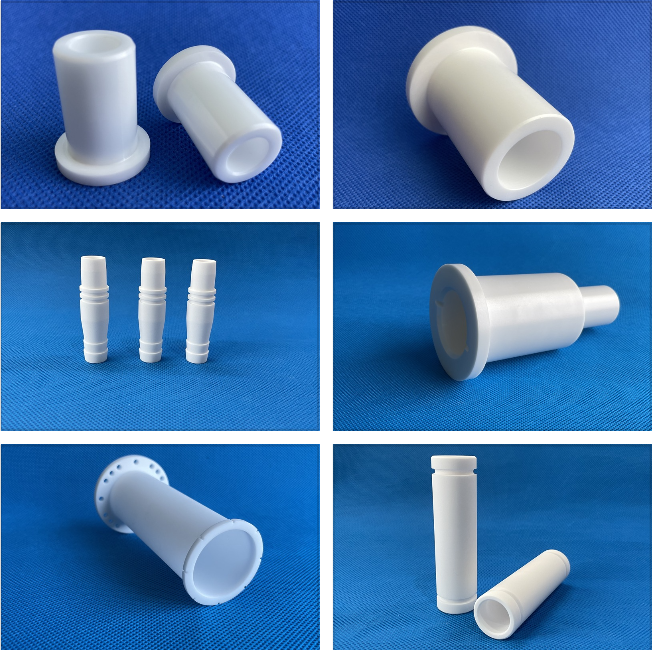

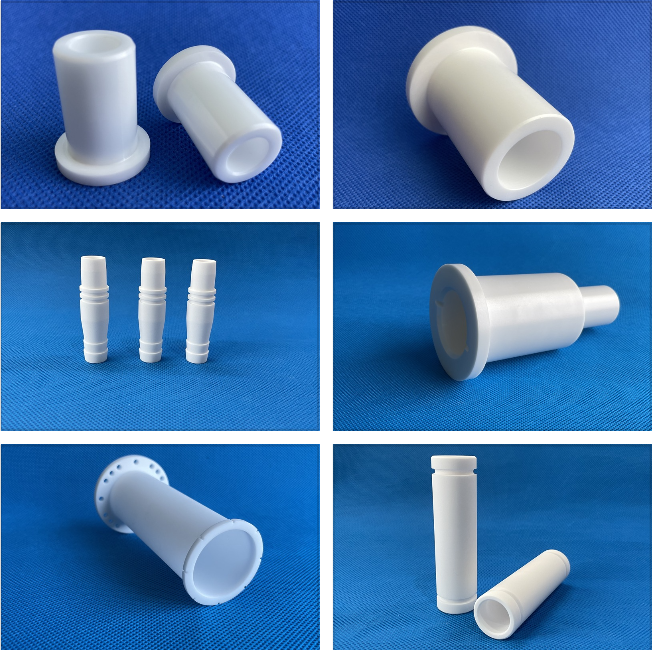

Ceramic tube with flange Alumina Ceramic Sleeves Lined Pipe With Flange

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC

- Sizes:Mini-OD: 0.02mm;Max-length: 500mm

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation...

- Customized:Can be custom for special sizes and shapes

1. Factory price and shipment within 24 hours In stocks

2. MOQ:1qty

3. Payment Term: PayPal; T/T; L/C etc.

4. Shipment: by sea by air by courier by post etc.

Flanged Alumina Ceramic Tube Customized Alumina Ceramic Sleeves Lined Pipe With Flange

Alumina ceramic flange sleeve (Flanged Alumina Ceramic Tube) is an industrial component that combines the material properties of alumina ceramics with the flange sleeve structure.

alumina ceramic tubes with flange

The following is a detailed introduction from the aspects of its material properties, application fields, advantages and manufacturing processes:

1. Material properties

· High hardness and wear resistance

The Rockwell hardness (HRA) of alumina ceramics reaches 80-90, and the wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high chromium cast iron, which significantly extends the service life of the equipment.

· High temperature resistance and chemical stability

It can be used for a long time in a high temperature environment of 1500-1750℃, resistant to acid and alkali corrosion, and suitable for highly corrosive medium environments.

· Lightweight and insulation

The density is only half of that of steel (3.7-3.95g/cm³), which reduces the load on the equipment; at the same time, it has high insulation strength (15-20KV/mm), which is suitable for electrical insulation scenarios.

2. Application fields

· Pipeline connection and sealing

It is used for sealing connection between cast iron, rubber-lined, non-ferrous metal pipelines and process equipment, flange valves, especially as wear-resistant and corrosion-resistant connection parts in harsh environments of erosion and wear.

· High-temperature industrial equipment

It is suitable for high-temperature scenes such as industrial furnaces, thermocouple protection tubes, electric heaters, etc., as a key component to withstand extreme temperatures and chemical corrosion.

· Semiconductors and precision manufacturing

In semiconductor manufacturing processes such as CVD, ion implantation, and photolithography, alumina ceramic flange sleeves have become ideal structural materials due to their high purity and low thermal expansion.

3. Core advantages

· Extremely long service life

Under the same working conditions, the service life of alumina ceramic flange sleeves is more than ten times longer than that of traditional metal materials, significantly reducing maintenance costs.

· Environmental adaptability

It is rust-proof and oxidized, suitable for extreme environments such as strong acid and alkali, high wear, etc., to ensure long-term and stable operation of equipment.

· Structural reliability

The flanges are used in pairs, and through bolt tightening and sealing gaskets, high-strength connection and sealing between pipelines are achieved to ensure system safety.

4. Manufacturing process

· Molding technology

Dry pressing, isostatic pressing and other processes are used to ensure product dimensional accuracy and internal structural uniformity to meet the needs of complex working conditions.

· Sintering and processing

Sintering at a high temperature of 1600-1700℃, combined with deep processing such as inner and outer circle fine grinding and polishing, grooving, and drilling, to achieve high-precision manufacturing with a tolerance control of ±0.01mm and a finish of 0.2.

· Customized service

Mingrui Ceramics supports customization according to drawings and samples, and can produce special-shaped and special-shaped ceramic parts to meet the personalized needs of non-standard equipment and special scenarios.

As a ceramic tube factory, us produce and sales ceramic tube with flange, one head or both head flanges.more sizes online.

Dimensions for flanges and ceramic tubes we can support to custom service for our customer requirements.

Key parameters control capability:

|

Max. diameter

|

To be 550mm

|

Min. diameter |

0.25mm

|

|

Precision process

|

CNC machining, grinding, lapping

|

Min. tolerance

|

+/-0.005mm

|

|

Roundness

|

0.005mm

|

Flatness

|

0.002mm

|

|

Roughness

|

Best to be Ra0.025

|

Liner straightness

|

0.01mm

|

|

Surface finish

|

Glazed, polishing or metalized

|

|

Visual quality:

1. No cracks, no dark dots, no contamination, and sharp edges;

2. Evenly distributed glaze with a very smooth surface

|

Application:

Ceramic flange tube commonly used as function and engineering ceramic components, widely used in electric power, metallurgy, mineral, coal, and chemical industryand others applications...

1.Material: aluminum oxide ceramics from 95% to 99.99% range/zirconia ceramics

2.Available type: threaded ceramic tube, alumina stepped tube, slotted ceramic tube available

3.Design capability: Both end open, one end open, half tube, rod available

4.Prototype to mass production capability

5.Features: High insulation, anti-chemistry, exceptional wear resistance, resistant high temperature, excellent physical properties.

Do not find similar ceramic tubes products on this page?

For more detail like price,shipping,samples...

Quick Free Quote . Our official E-mail: admin@cerampart.com (Mr admin).thanks

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730