Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

As a Professional Advanced Technology Ceramic Manufacturers, Us Support To Customize Different Specifications Of Ceramic Components

|

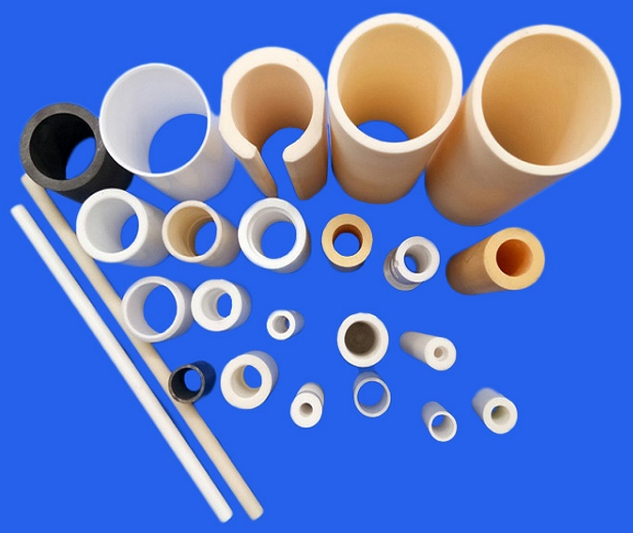

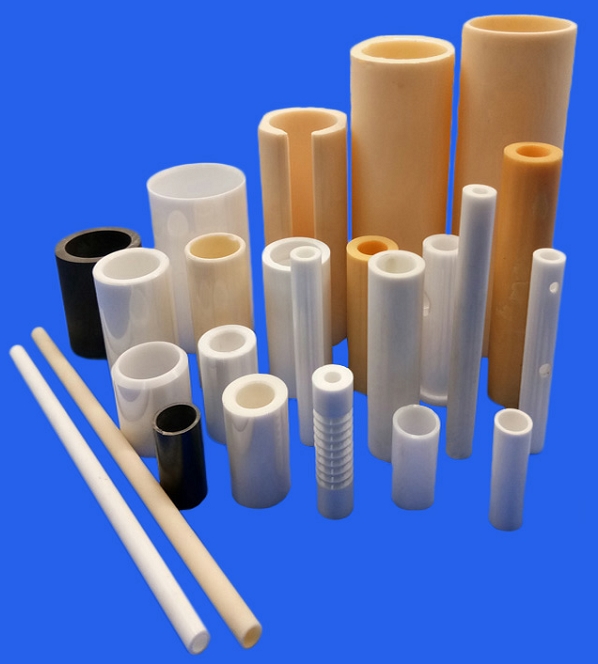

Ceramic tube have a best performance for industry. which made of the advance ceramic raws: 95%-99.99% alumina ceramic(Al2O3); zirconia ceramics; silicon carbide ceramics; silicon nitride ceramics..etc 1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)... 2. Hardness Strength, Wear Resistance Up To Mohz 9.0 ; HRA 80-90... 3. High Voltage, Good Insulation Performance ,Electrical Resistivity Up To 10∧14 Ohm.Cm... 4. High Polished Surface Up To Rz0.8(Ra0.1) ... 5. Superior Mechanical Strength, MAX 10 MPa.m1/2 Fracture toughness, 6. Pressure Resistance, Max 2300MPa compressive strength... 7. Anti-High Corrosion Resistance, Such As Acid Alkali Resistance... 8. Long Service Life... 9. Other excellent property The hole of ceramic tubes: Single bore, double bore, four bore, dee tubing, oval shapes, Flange, taper, thread, nozzle, custom shapes... |

|

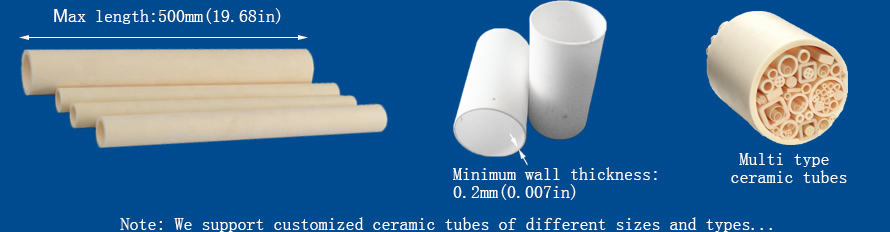

The sizes of some ceramic tubes we made are shown below:

| Length Range | Length Range | Outside Diameter | Outside Diameter | Inside Diameter | Inside Diameter |

| 4.000-6.875 in | 102-174 mm | 0.031 in | 0.79 mm | 0.005 in | 0.13 mm |

| 4.000-6.875 in | 102-174 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 4.000-6.875 in | 102-174 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 6.876-12.875 in | 175-327 mm | 0.047 in | 1.19 mm | 0.01 in | 0.25 mm |

| 6.876-12.875 in | 175-327 mm | 0.156 in | 3.96 mm | 0.031 in | 0.79 mm |

| 4.000-6.875 in | 102-174 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 6.876-12.875 in | 175-327 mm | 0.062 in | 1.57 mm | 0.016 in | 0.41 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.031 in | 0.79 mm |

| 12.876-18.875in | 328-479 mm | 0.187 in | 4.75 mm | 0.047 in | 1.19 mm |

| 4.000-6.875 in | 102-174 mm | 0.094 in | 2.39 mm | 0.02 in | 0.51 mm |

| 12.876-18.875in | 328-479 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

| 4.000-6.875 in | 102-174 mm | 0.125 in | 3.18 mm | 0.02 in | 0.51 mm |

| 4.331-13.858 in | 110-352 mm | 0.205 in | 5.21 mm | 0.031 in | 0.79 mm |

| 8.268-16.142 in | 210-410 mm | 0.250 in | 6.35 mm | 0.062 in | 1.57 mm |

| 3.543-13.780 in | 90-350 mm | 0.258 in | 6.56 mm | 0.062 in | 1.57 mm |

| 6.876-12.875 in | 175-327 mm | 0.340 in | 8.64 mm | 0.241 in | 6.12 mm |

| 12.876-18.875in | 328-479 mm | 0.367 in | 9.32 mm | 0.275 in | 6.98 mm |

| 12.876-18.875in | 328-479 mm | 0.433 in | 11.00 mm | 0.329 in | 8.35 mm |

| 4.000-6.875 in | 102-174 mm | 0.520 in | 13.22 mm | 0.313 in | 7.95 mm |

| 12.876-18.875in | 328-479 mm | 0.627 in | 15.93 mm | 0.399 in | 10.13 mm |

| 4.000-6.875 in | 102-174 mm | 0.880 in | 22.35 mm | 0.486 in | 12.35mm |

| 3.740-15.708 in | 95-399 mm | 1.243 in | 31.56 mm | 0.774 in | 19.65 mm |

| 5.905-16.929 in | 150-430 mm | 1.561 in | 39.65 mm | 1.177 in | 29.89 mm |

| Round Double Bore | Round Four Bore | Oval Double Bore | |||

| OD | ID | OD | ID | OD | ID |

| .063" | .016" | .063" | .016" | .077"/.051" | .014" |

| .094" | .025" | .094" | .020" | .120"/.070" | .031" |

| .109" | .031" | .109" | .020" | .163"/.112" | .040" |

| .125" | .031" | .188" | .031" | ||

| .125" | .040" | .219" | .050" | ||

| .156" | .052" |

Lengths available up to 60" long on all tubes |

|||

| .188" | .040" | ||||

| .200" | .052" | ||||

|

User industries automotive, aviation, space travel electrical and thermal insulation electronics and sensors energy technology, power generation environmental technology fluid technology friction-reduction, wear- and corrosion -protection high temperature applications laboratory technology laser technology mechanical and chemical process engineering metal industry optics semiconductor processing equipment surface treatment vacuum technology |

Other types of ceramic tubes are displayed

|

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

Customization & Machining Service

As a professional manufacturer of industrial ceramic components.We can custom the sepcial specifications of ceramic tubes, rod or other ceramic parts.High quality,Factory price, on-time delivery, High composition of ceramics

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-10 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS