Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

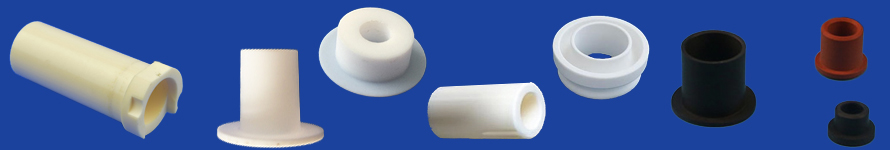

The ceramic tube of bushing sleeve as a kind of the tubes which have a excellent features like wear resistance, High strength rigidity, high temperatures resistance, insulating ...etc. both of them was made of the advance technical ceramics:95%--99.99% Alumina(Al2O3), Zirconia(ZrO2) ,Silicon Carbide,Silicon Nitride ...etc

| Type of ceramic tubes us manufacturer (including but not only belows) | |||||||

|

Socket tube Insulated tube Inner core |

Filtting tube Heating tube Radiant tubes |

Pump body tube Inner liner tube Round tube |

Bushing tube Roller tube Single / mutli holes tube |

||||

|

Dimension :

|

|

|

Inside Diameter as small as 0.3 mm

|

Longth as long as 500mm, as short as 0.5mm

|

|

Inside Diameter tolerance as 0.002mm

|

Outside Diameter tolerance as fine as 0.001mm

|

|

Minimum thickness of tube wall:0.2mm

|

The length and special sizes can be customized

|

Ceramic features:

1. Refractory, High Temperature Resistance, Maximum Used Temperature: 1800 ºC (3272ºF)... |

User industries automotive, aviation, space travel electrical and thermal insulation electronics and sensors energy technology, power generation environmental technology fluid technology friction-reduction, wear- and corrosion -protection high temperature applications laboratory technology laser technology mechanical and chemical process engineering,metal industry,optics semiconductor processing equipment surface treatment vacuum technologyd |

| · Flexural strength | · Chemical resistance | · Electrical insulation | · Corrosion resistance | · Dielectric strength |

| · Wear resistance | · Temperature resistance | · Thermal conductivity | · High voltage | · Hardness... |

|

Customization & Machining Service: As a ceramic parts manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS