Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

The al2o3 alumina ceramic parts as a kind of the industry equipment spare components was made of the mainly alumina ceramics raws:95% — 99.99%. The different chemical composition and structure of alumina ceramics determine their different special properties and functions, such as high strength, high hardness, high toughness, corrosion resistance, etc.

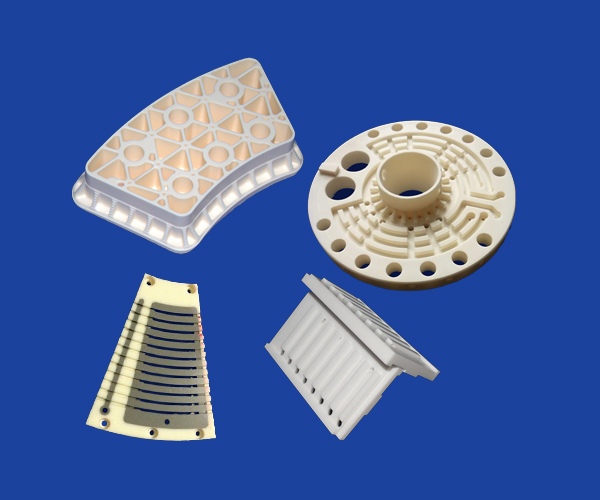

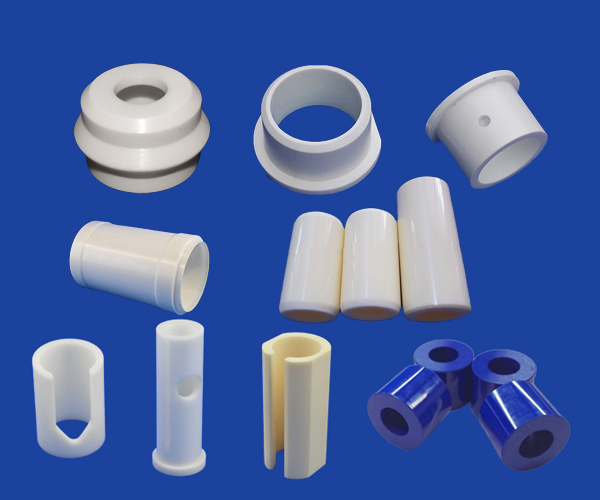

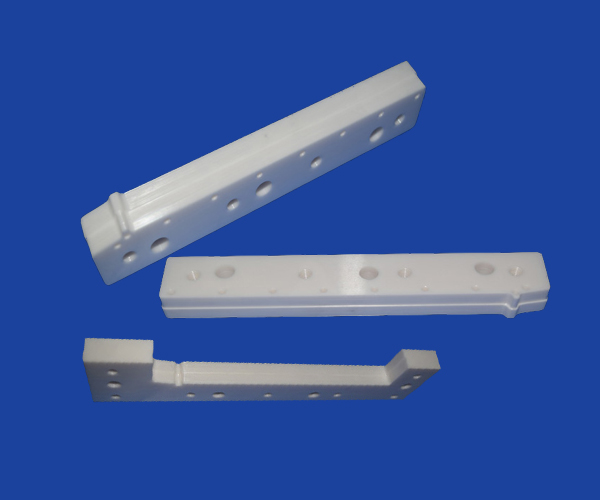

Alumina ceramic part type:

Alumina ceramic tube part

Alumina ceramic rod part

Alumina ceramic plate part

Alumina ceramic bushing part

Alumina ceramic flange part

Alumina ceramic gear part

Alumina ceramic sheet part

Alumina ceramic pump part

Alumina ceramic shaft part

Alumina ceramic sealing part

Alumina ceramic ring part

Alumina ceramic insulator part

Alumina ceramic liner part

and other types

Properties of Alumina/Aluminum Oxide (Al2O3)

1.Very good electrical insulation (1x1014 to 1x1015 Ωcm)

2.Moderate to extremely high mechanical strength (300 to 630 MPa)

3.Very high compressive strength (2,000 to 4,000 MPa)

4.High hardness (15 to 19 GPa)

5.Moderate thermal conductivity (20 to 30 W/mK)

6.High corrosion and wear resistance

7.Good gliding properties

8.Low density (3.75 to 3.9 g/cm3)

9.Operating temperature without mechanical load 1,000 to 1,500°C.

10.Bioinert and food compatible

User industries

automotive, aviation, space travel

electrical and thermal insulation

electronics and sensors

energy technology, power generation

environmental technology

fluid technology

friction-reduction, wear- and corrosion -protection

high temperature applications

laboratory technology

laser technology

mechanical and chemical process engineering

metal industry

optics

semiconductor processing equipment

surface treatment

vacuum technology

|

|

|

|

Alumina ceramic component parts customization:

Parts customization, due to the product size, material, processing accuracy and other requirements, resulting in the cost of materials, processing costs, packaging logistics costs will be different.

Please be sure to contact us when ordering, as much as possible to provide parts information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.), we will recommend for you to meet your requirements of the product program and quotation.

Our official e-mail: admin@cerampart.com

Alumina Ceramic Part Parameters

| Properties | Unit | Alumina (AL2O3) | |||

| AL2O3≥95 | AL2O3≥99 | AL2O3≥99.5 | AL2O3≥99.8 | ||

| Volumetric density | g/cm3 | 3.7 | 3.80-3.85 | 3.85 | 3.9 |

| Hardness | HRA≥ | 86 | 88 | 88 | 88 |

| Flexural Strength | Mpa≥ | 300 | 350 | 400 | 400 |

| Maximum temperature | ℃ | 1500 | 1500 | 1500 | 1500 |

| Line expansion coefficient | ×10-6/℃ | 7.5 | 8.2 | 8.2 | 8.2 |

| Dielectric constant | εr(20℃,1MHz) | 9 | 9.2 | 9.2 | 9.2 |

| Media loss | tanδ×10-4,1MHz | 3 | 2 | 2 | 2 |

| Volumetric resistivity | Ω·cm(20℃) | 1013 | 1014 | 1014 | 1014 |

| Breakdown strength | KV/mm,DC≥ | 20 | 20 | 20 | 20 |

| Acidic resistance | mg/cm2≤ | 0.7 | 0.7 | 0.7 | 0.7 |

| Alkaline resistance | mg/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Abrasion resistance | g/cm2≤ | 0.2 | 0.1 | 0.1 | 0.1 |

| Compressive strength | Mpa≥ | 2500 | 2500 | 2500 | 2800 |

| Flexural Strength | Mpa≥ | 200 | 350 | 350 | 350 |

| Thermalcoefficient | W/m·K(20℃) | 20 | 25 | 25 | 25 |

| Precision of manufacture | |

| Dimensional accuracy | Up to 0.001mm |

| Smoothness | Highest possible mirror |

| Concentricity | Up to 0.003mm |

| Parallelism | Up to 0.002mm |

| The inner hole tolerance | The minimum 0.005mm |

| Straight flute | The narrowest 0.1x100mm |

| The thickness of the size | Minimum to 0.02mm |

| The screw thread | Minimum internal thread M2 |

| Cylindricity | Up to 0.004mm |

| The linear tolerance | Up to 0.001mm |

| The smallest aperture | The minimum 0.07mm |

| Precision process | CNC maching,grinding,lapping |

| Surface finish | Glazed,polishing or metallized |

|

Visual quality: 1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

| For more information about alumina ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS