Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730The machining method of ceramic parts surface depends on the technical requirements of ceramic parts surface.However, it should be noted that these technical requirements are not necessarily the requirements specified in the ceramic part drawing, and may be higher than the requirements on the ceramic part drawing in some way because of the ceramic part technology.For example, the machining requirements on the surface of some ceramic parts are raised due to the non-coincidence of the datum.Or because it is used as a fine benchmark and may put forward higher processing requirements.

When the technical requirements of the machining surface of each ceramic part are clarified, the final machining method that can guarantee the requirements can be selected accordingly, and the number of working steps and the machining method of each working step can be determined.The selected machining method of ceramic parts should meet the requirements of parts quality, good machining economy and high production efficiency.To this end, the following factors should be considered when selecting the processing method:

1. There is a large range of machining accuracy and surface roughness that can be obtained by any method of ceramic parts, but it is economical only within a narrow range, and the machining accuracy of this range is economical machining accuracy.Therefore, when selecting the machining method of ceramic parts, the corresponding machining method that can obtain the economic machining precision should be selected.

2. The nature of the materials used to process ceramic parts should be considered.

3. The structure shape and size of ceramic parts processing should be considered.

4. The productivity and economic requirements of ceramic parts should be considered.When producing in large quantities, advanced technology with high efficiency should be adopted.Even can fundamentally change the blank manufacturing method, can reduce the amount of machining labor.

5. Take into account the existing equipment and technical conditions in the ceramic parts factory or workshop.Selection of processing methods should make full use of the existing equipment, mining enterprise potential, give play to the enthusiasm and creativity of workers.However, continuous improvement of existing processing methods and equipment, adoption of new technologies and improvement of process level should also be considered.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

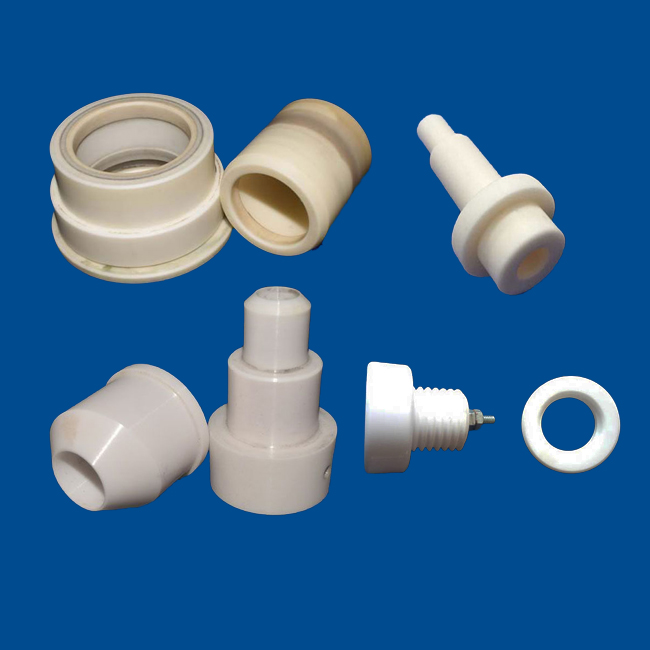

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS