Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730Ceramic mould for machining ceramic workpiece

Ceramic precision mold machining ceramic workpiece CNC machining experience improvement project

Recent company to undertake a ceramic precision mold processing project high precision requirements, the mould size accuracy within 0.01 mm, in not only runs the largest CNC process using optimization technology to ensure precision, also at the scene of the ceramic workpiece processing to optimize the management to ensure the processing quality of qualified, will now be part of the process implementation countermeasure summary is as follows:

Visual management of ceramic precision mold machining of precision ceramic parts:

1. Measures: Set up independent logistics and storage area for precise ceramic workpiece;

2. Role: Distinguish the high-precision ceramic parts clearly to ensure that the machining personnel clearly know the accuracy requirements of the workpiece, and carry out necessary control and protection from each link of the processing

3. Confirmation of ceramic precision mold processing equipment and personnel

1. Measures: test the accuracy of machine tools before ceramic processing, screen the machine tools with excellent accuracy, and assign excellent operators with ceramic parts processing skills to take on the processing tasks;

2. Role: Ensure the machining precision from the aspects of human and machine, avoid the influence of equipment precision and personnel skills on the precision;

Ceramic precision mold processing Ceramic parts processing tool to increase the detection accuracy in the machine steps:

Measures:

(1) After the tool library is installed, use the tool tester to detect the tool, the accuracy is guaranteed within 0.01;

(2) After loading the tool into the spindle, the detection tool can be placed within 0.01 before starting the processing;

Role: Tool precision is very important to CNC machining precision. It can eliminate the influence of abnormal tool precision caused by twice assembly of the tool on machining quality through the second confirmation of the tool in the machine.

The precision of ceramic precision mold is confirmed three times before, during and after processing:

Measures:

1. The main insert of each ceramic part shall be tested for three times during the processing:

Incoming material accuracy detection.

2. In-machine detection of workpiece accuracy after ceramic parts processing is completed.

3. Three-dimension test of IPQC process.Three tests using the same photoelectric probe!

Objective: The workpiece with error within 10 in the three tests is qualified.Before to after, the whole process to control the workpiece accuracy;Facilitate the first time to take corrective action.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

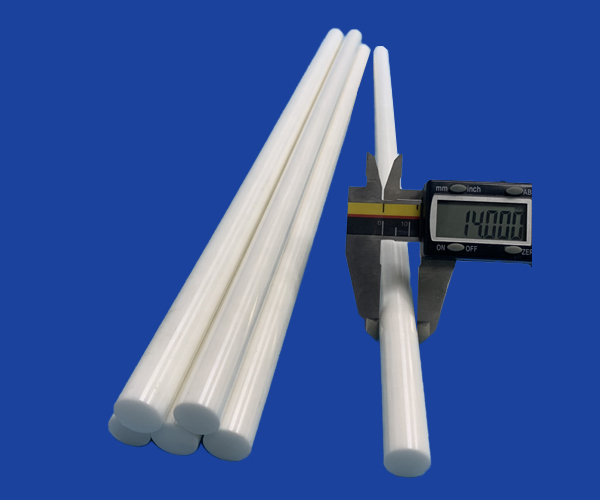

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS