Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 181229747301. Actively innovate the processing equipment of ceramic parts

In order to maximize the application effect of ceramic parts processing technology, it is necessary to combine the characteristics of ceramic parts processing technology, analyze the processing equipment of ceramic parts, and innovate the processing equipment and technology of ceramic parts.Innovation is the key content to lead the development, ceramic parts processing and manufacturing enterprises must actively realize self-innovation, the original ceramic parts processing equipment for innovative transformation, so that ceramic parts processing equipment more suitable for CNC machining machine, so as to enhance the actual efficiency of ceramic parts processing.Mastering key technology, the research and development personnel must be active to raise their scientific research level, and draw lessons from, learning experience and technology, actively into the cause of ceramic parts processing equipment innovation, timely find ceramic parts processing equipment, the aging problems, and targeted to solve the problem, ensure that innovative ceramic parts processing equipment.

2.Fully realize automatic editing of ceramic parts processing

Intellectualization is the only way to develop in the field of ceramic parts processing and manufacturing. In the production process of many ceramic parts processing and manufacturing enterprises, the program is generally set by the personnel in advance, so as to control the equipment parameters and processing steps of ceramic parts.In the current Internet innovation, technological innovation, the traditional form of artificial programming has been gradually replaced.Manual setting of ceramic parts processing procedures can ensure production efficiency, but it is easy to have errors, and it needs to adjust the time.In view of the future development stage, the ceramic parts processing automatic programming trend is ready for development, in order to achieve the efficiency of ceramic parts processing and manufacturing enterprises, it is necessary to actively integrate artificial intelligence technology, automatic programming technology, automatic ceramic parts processing programming, and put it into the production practice quickly.

3. Rational choice of machine tools

In the processing of modern ceramic parts, the quality of cutting tools directly affects the processing quality of ceramic parts.Then you can use ceramic parts processing technology, rational choice of tool for the machine tool, from the level of precision and quality, the choice of tool is highly valued.Ceramic parts manufacturing enterprises must combine different processing requirements of ceramic parts, select the corresponding machine tools, on the basis of meeting the processing needs of ceramic parts, to avoid the impact of machine tool errors on the processing products of ceramic parts.For example, in the cutting process, the appropriate choice of flat cutting tools to enhance the cutting efficiency, to ensure the quality of parts processing.

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

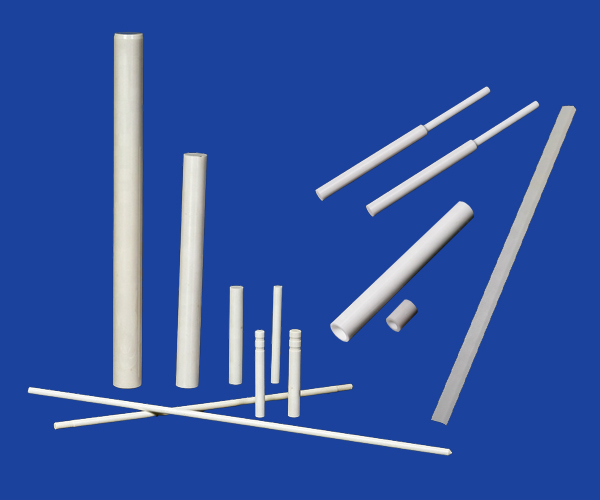

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS