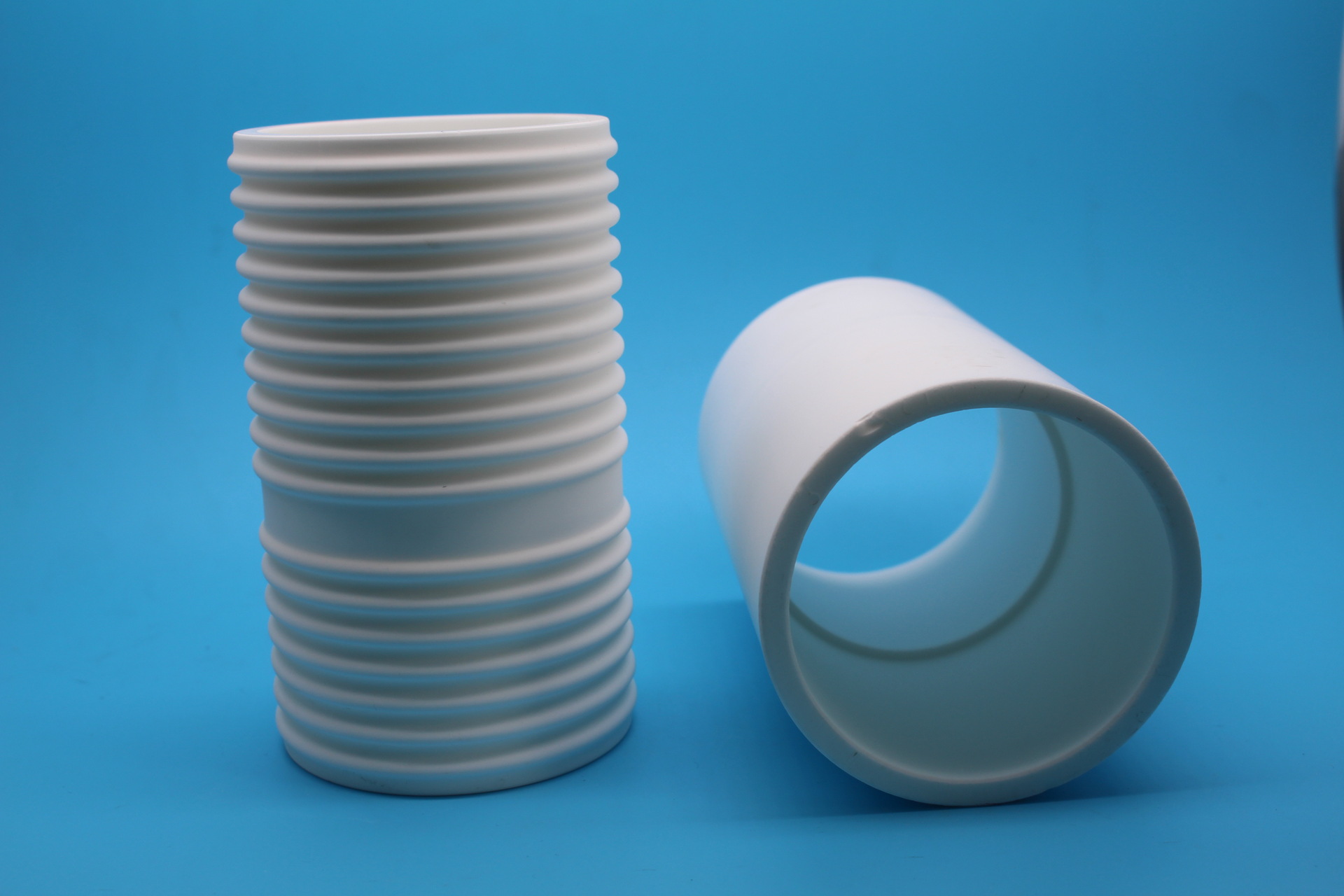

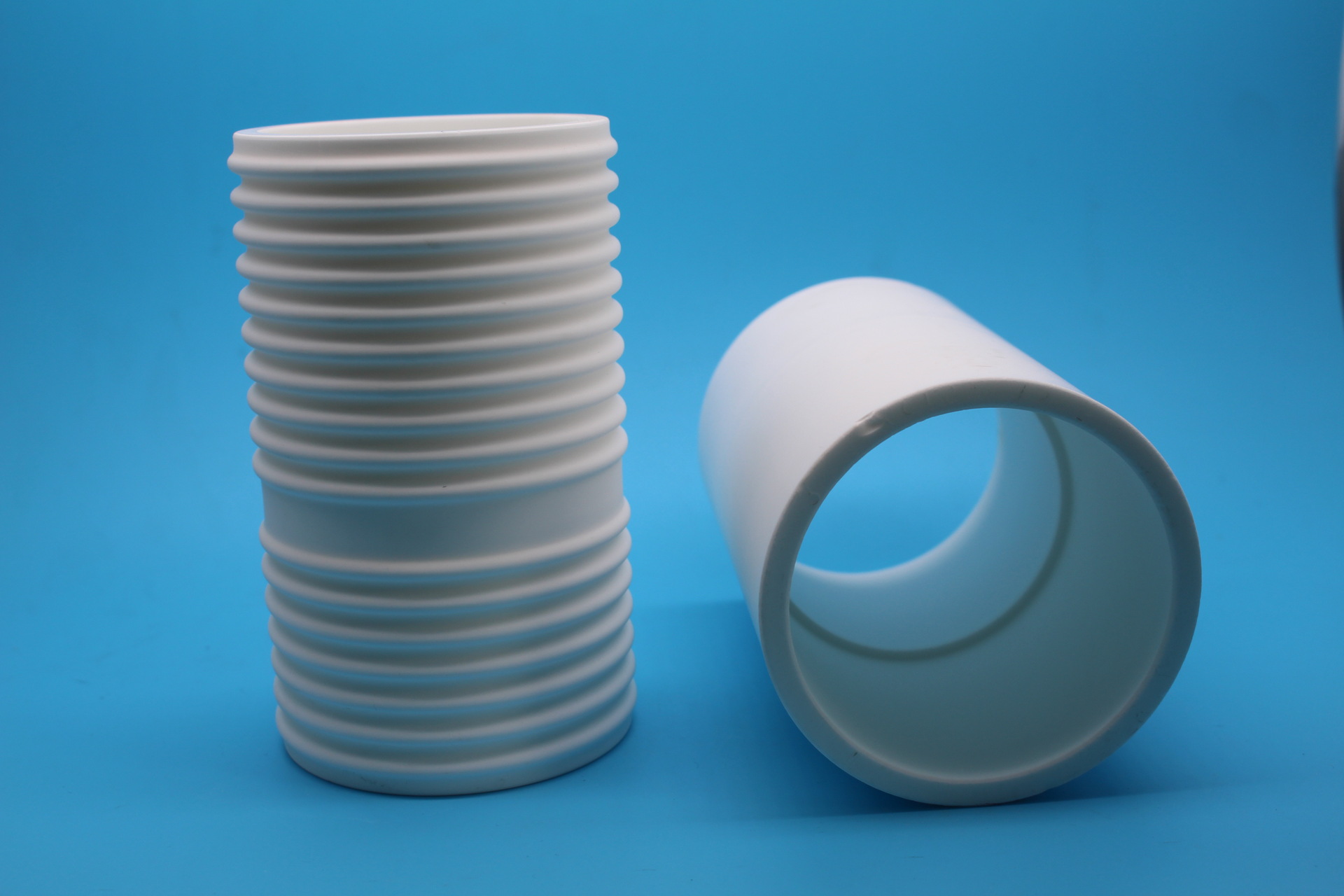

Type of thread machining for ceramic parts

Thread milling of ceramic parts

Ceramic parts processing center can use thread milling cutter for thread direct processing, which is also a relatively common treatment scheme in the market at present, in more complex ceramic parts thread processing and large hole thread processing operations are widely used, the advantage is also very obvious.

The thread milling method in CNC ceramic parts processing mode can obtain high machining precision of ceramic parts and at the same time ensure a fairly fast machining speed.

For ceramic parts, the same tool can be used for right or left thread treatment.

Because the thread milling of ceramic parts has outstanding economic benefits, it has become a common process in CNC machining center.

Thread milling of ceramic parts can also be applied to the processing of different materials and complex materials, such as copper or stainless steel materials, thread milling method can ensure the processing accuracy.

Tap machining of ceramic parts

Ceramic parts tap processing is also a common ceramic parts processing technology, generally suitable for small diameter thread processing, but the accuracy is relatively poor.

So if you meet the high precision requirements of ceramic parts processing needs, should avoid using tap processing method.

In order to keep the tap processing method of ceramic parts, should choose the appropriate drilling tie-in corresponding bit diameter, to ensure that the diameter of the tap on the ceramic parts tolerance limit can coordinate with each other, this can effectively reduce the follow-up work, tap processing workload of ceramic parts, at the same time reduce the tap processing method in the actual processing of the damage probability of the tap.

The damage of taps is mainly due to the difficulty in forming a harmonious relationship between taps and processed materials, which can easily lead to damage of taps or deterioration of durability.

At present in the actual production, there are mainly through hole tap and blind hole tap which are widely used.

In the production of ceramic parts should be combined with the needs of thread processing for a reasonable choice.

3. Bucking process for ceramic parts

The bucking method of ceramic parts is seldom used in the actual production and processing. It is generally used as an emergency method in the absence of thread milling tools and taps.

Generally used in the case of ceramic box parts need to make a large threaded hole, the need to use the screw turning tool and boring tool bar to boring pin processing.

In the process of ceramic parts processing, we should first pay attention to the spindle speed, for the spindle rotation early prone to delay and other phenomena, to carry out effective control, so as not to affect the thread processing because of the improper speed.

In the processing of multiple knife rods, the positions between the knife rods should be ensured, and the corresponding positions between the knife rods and the knife groove should be consistent, so as to avoid the phenomenon of disorderly buckle, which will affect the processing effect of the final product.

In the processing method, to avoid a knife pick, as much as possible for the treatment of multi-knife operation, in order to better improve the effect of thread processing.

In actual production, due to low efficiency, it is not suitable for large-scale promotion and application in ceramic parts processing, so it can only be used as an emergency backup plan.

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730