Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730

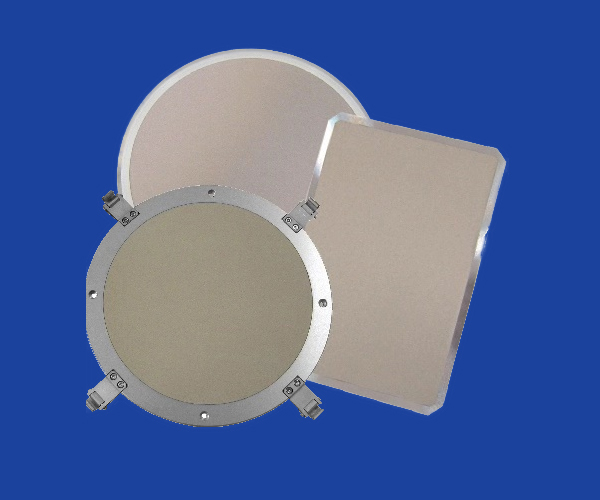

Ceramic Vacuum Chuck Widely used as the basic materials of various industrial products, such as filter, refractory, kiln furniture, absorbent, sound absorbent, lightweight structural materials, thermal insulation materials.

In particular, vacuum absorption technology with high precision and high performance is an ultra-thin object required for semiconductor, LED and display production.

Round

Rectangular

Multi-zone

The Ceramic Vacuum Chuck can be made flat and parallel to 0.001 "across the surface.Customers only need to provide vacuum pump or internal vacuum with 1 "or -" NPT accessories.Alternatively, light machining provides a vacuum pump containing all the tubing and fittings required for operation (see below).

The units are less than 1.5″ in height, and are all “lightweight.”

6″ Square vacuum surface with 20 micron pore

6″ Round vacuum surface with 20 micron pore

12″ vacuum surface with 20 micron pore

Drawing for the 6 inch square, 6 inch round, 12 inch square and 12 inch round.

6″ < x < 12″: (square or rectagular)

x < 6″: (square or rectangular)

6″< x < 12″: (round)

< 6″: (round)

|

Customization & Machining Service: As a ceramic plates manufacturer,us offer a wide of the ceramic specification,and customized&machinables. Get a Quote On Your Customized Now!! or up a files by EMAIL. Our Custom Capabilities: 1.High Purity Martoxid Powder 2.OEM Support, More Than 10 Technicians With 5-Year R&D Experience 3.35000 ㎡workshop, annual output could reach hundred million pieces. 4.All crafts are inspected strictly based on drawings,checked each month. 5.Best Service And Quick Delivery Via Fedex,DHL,UPS,TNT Etc. |

|

|||||||||||||||||||||||||||

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.

Feedback

1. For any query or doubt, please contact us firstly, we will update with you soon;

2. For any other satisfaction, please also feedback to us, which could improve our service better and better.

| For more information about ceramics parts,please contact our engineers in time >>> |

|

Ceramics quality Ceramics Process Ceramice after-sale Customer witness Patent Certificate

Ceramic Flange Ceramic BushingS Ceramic PlungerS Ceramic Pump ValveS