Ceramic Roller Tube

- Materials:Alumina (Al2O3)/ Zirconia(ZrO2) /Si3N4 /SiC ...etc

- Sizes:Mini ID:0.3mm;Mini length:0.5mm;Max length: 4800mm

- Delivery times:2 -25 days(depends on the quantity)

- Precision:Ra 0.1um tolerance: 0.001mm... etc

- Features:Heat resistance / Wear resistance / High purity / Refractory / High Corrosion / Good Insulation

- Customized:Can be custom for special sizes and shapes

1. Factory price and shipment within 24 hours In stocks

2. MOQ:1qty

3. Payment Term: PayPal; T/T; L/C etc.

4. Shipment: by sea by air by courier by post etc.

Ceramic Roller Tube With Refractory Heat Temperature Alumina Ceramic Roller

As a Professional Advanced Technology Ceramic Manufacturers,

Us Support To Customize Different Specifications Of Ceramic Components

Ceramic roller is produced by technical ceramics such as Alumina Oxide (Al2O3),Silicon Nitride (Si3N4), Zirconium Oxide (ZrO2) or Silicon carbide (SiC)... etc. which is suitable for the production of daily porcelain in the roller kiln and electric furnace.

Ceramic roller has excellent bending strength at high temperatures, products for fire within 1750 ℃ (extremely reliable thermal stability and excellent thermal shock performance.

Alumina ceramic roller is an essential component of modern high temperature roller kilns.

Ceramic roller is a kind of high temperature and high strength, high hardness, wear resistance, corrosion resistance and can be self lubrication of high temperature ceramics, using temperature as high as 1750 ℃, with excellent corrosion resistance, except hydrofluoric acid, and other kinds of acid corrosion, and alkali resistance, all kinds of metal corrosion, and it has excellent electrical insulation and radiation resistance.

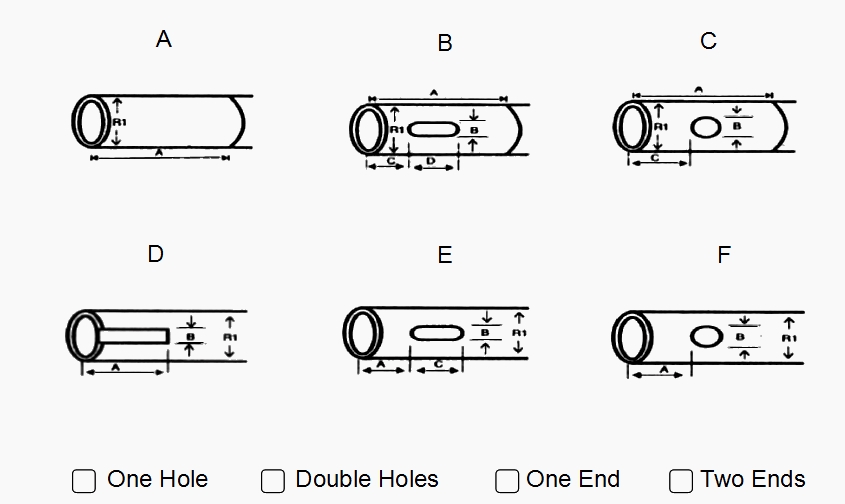

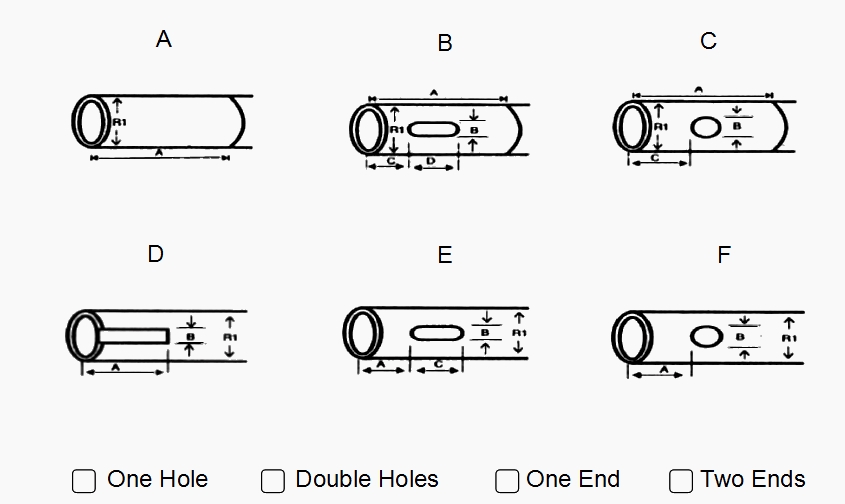

Part of ceramic roller sizes:

|

Diameter (mm) |

Length (mm) |

Diameter (mm) |

Length (mm) |

|

65--75mm |

3000--4820 |

40mm |

2000--3500 |

|

60mm |

2700--4800 |

36mm |

2000--3300 |

|

55mm |

2700--4700 |

35mm |

2000--3200 |

|

50mm |

2400--4600 |

33.7mm |

1800--3100 |

|

45mm |

2200--3800 |

30mm |

1600--3100 |

|

42mm |

2200--3800 |

25mm |

1600--3100 |

The ceramic roller of the above sizes , we have available stocks. We can also custom cut shorter lengths to your specifications. Other sizes available on request.

Product features: |

|

1. The hardness

Alumina ceramic roller rockwell hardness of hra80-90, hardness is second only to diamond, far more than the wear resistance of steel and stainless steel.

2. Excellent wear resistance

Wear resistance is 266 times that of manganese steel and 171.5 times that of high chromium cast iron.Under the same working condition, the service life of the equipment can be extended by at least 10 times.

3. Light weight

Its density is 3.6g/cm3, only half of the steel, which can greatly reduce the load of equipment.

Ceramic materials:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2) · YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)...

|

Properties |

Units |

AL2O3 |

ZrO2 |

SiC |

Si3N4 |

|

Density |

g/cm3 |

3.65-3.93 |

5.95-6.0 |

3.12 |

3.23 |

|

Water absorption |

0 |

0 |

0 |

0 |

0 |

|

Coefficientof thermal expansion |

10-16/k |

7.9-8.5 |

10.5 |

3 |

3.2 |

|

Modulus of elasticity young`s mod |

GPa |

280-340 |

210 |

440 |

300 |

|

Poission`s ratio |

/ |

0.21-0.22 |

0.3 |

0.17 |

0.26 |

|

HV hardness hv |

MPa |

1650 |

1300-1365 |

2800 |

1500 |

|

Flexural strength |

MPa |

310 |

950 |

390 |

720 |

|

Flexural strength(700℃) |

MPa |

230 |

210 |

380 |

450 |

|

Compressive strength |

MPa |

2200 |

2000 |

1800 |

2300 |

|

Fracture toughness |

MPa*m1/2 |

4.2 |

10 |

3.9 |

6.2 |

|

Heat conductivity |

W/m*k |

26-30 |

2-2.2 |

120 |

25 |

|

Electrical resistivity |

Ω*mm2/m |

>1016 |

>1015 |

>103 |

>1013 |

|

Max use temperature |

℃ |

1750 |

1050 |

1550 |

1050 |

|

Resistance to acid alkaline |

/ |

high |

high |

high |

high |

|

Dielectric constant |

/ |

9.6 |

29 |

9.66-10.03 |

/ |

|

Dielectric strength |

KV/mm |

8.7 |

9 |

/ |

/ |

|

Thermal shock resistance |

△T(℃) |

180-220 |

280-350 |

230-260 |

/ |

|

Tensile strength |

MPa |

248 |

250 |

/ |

/ |

If a ceramic roller in specials of ceramics is required, please advise and we will be happy to quote. Larger or smaller size available by quotation.

|

Precision of manufacture |

|

Dimensional accuracy |

Up to 0.001mm |

|

Smoothness |

Highest possible mirror |

|

Concentricity |

Up to 0.003mm |

|

Parallelism |

Up to 0.002mm |

|

The inner hole tolerance |

The minimum 0.005mm |

|

Straight flute |

The narrowest 0.1x100mm |

|

The thickness of the size |

Minimum to 0.02mm |

|

The screw thread |

Minimum internal thread M2 |

|

Cylindricity |

Up to 0.004mm |

|

The linear tolerance |

Up to 0.001mm |

|

The smallest aperture |

The minimum 0.07mm |

|

Precision process |

CNC maching,grinding,lapping |

|

Surface finish |

Glazed,polishing or metallized |

Visual quality:

1. No cracks, no dark dots, no contamination and sharp edges;

2. Evenly distributed glaze with very smooth surface |

|

Ceramic roller precision process:

Raw materials-Molding process - Sintering - Machining & Grinding - Quality Inspector

Additional Information:

·Discounts on large quantities of Ceramic rollers

·In stock items will typically ship in a few working days.

·Unit price and estimated ship dates will be calculated when the length and quantity are specified.

·The length and special sizes can be customized

Customization:

As a manufacturer of ceramic parts, we offer customization of ceramic roller of special sizes and shapes.High Precision, Fast Delivery Time, High Composition (with test report).Get a Quote On Your Customized Now!! or attachs a specifications by EMAIL.

Lead time:

10-20 working days after comfirmed order. the samples within 3 days |

For more information about ceramics parts,please contact our engineers in time >>>

Moble: +86 18122974730

Moble: +86 18122974730 Phone: +86 746 3386888

Phone: +86 746 3386888 Email: admin@cerampart.com

Email: admin@cerampart.com Skype: +86 18122974730

Skype: +86 18122974730 Wechat: +86 18122974730

Wechat: +86 18122974730